3.1. Comparison of Metal Removal Efficiency

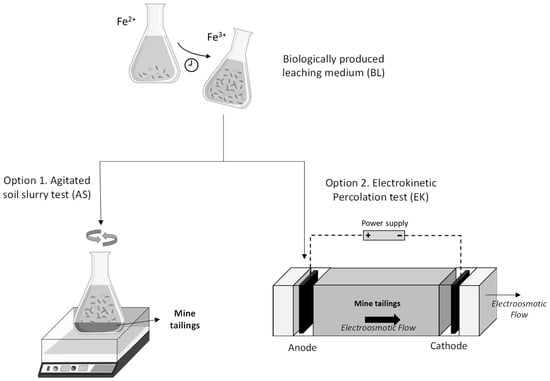

Figure 2 shows the percentages of metal leached from tailings corresponding to the agitated soil slurry system for the two treatments applied, i.e., with use of the BL medium and without it (using iron-free TK medium, which acts as the reference test). Throughout the experiment, the temperature and pH were maintained at 30 °C and 2.1 ± 0.1, respectively, to prevent the precipitation of solubilized metals. The concentration of Fe

3+ varied between 300 and 450 mg L

−1, while the redox potential ranged from 500 to 600 mV. After 15 days of bioleaching, a clear enhancement in metal solubilization when the BL medium was used, as compared to the reference tests, can be seen in

Figure 2 for Zn, Mn, Co, Ni, and Cr, while that effect was practically negligible for Cd.

It can be also observed in

Figure 2 that most of the leached metals were extracted within the first five days of the experiment and a plateau was reached from day 8 onwards, indicating that leaching nearly stopped. Our earlier research on the bioleaching of the same mine tailings used in the present work demonstrated that the presence of microorganisms in the tailings was poor. Therefore, the bioleaching rate is quite limited until the activation of the native microorganisms is accomplished [

21]. Thus, it can be said that the metal solubilization observed in the reference test was mainly caused by chemical leaching because of the acidity of the TK medium; the fact that the plateau after day 5 has a similar shape in the two treatments clearly shows the low degree of contribution of native microorganisms to metal leaching. Furthermore, the differences observed between the two treatments for each metal were due solely to the leaching effect caused by the BL medium; the Fe

3+ concentration coming from the BL medium was high enough throughout the experiment to be considered not to be a limiting reagent.

A previous study by Van Yken et al. [

23] investigated metal leaching from solid wastes, such as printed circuit boards, and compared the effectiveness of chemically versus biologically produced ferric sulfate; the results showed no significant differences between the two methods. This implies that the biologically produced lixiviant agent, mainly composed of sulfuric acid and ferric iron, can be used as an environmentally friendly leaching agent. Furthermore, Muravyov et al. [

24] studied the production and regeneration of ferric iron by acidophilic microbes for the processing of sulfidic ores with the aim of achieving an economical and sustainable two-step leaching process. They found that the bioregeneration of ferric iron was rapid and efficient and allowed for cost savings. This would reinforce our strategy of using the BL medium.

The leaching patterns corresponding to the EK-percolation treatment are shown in

Figure 3. It can be seen that Mn, Cd, Cr, and Zn exhibited similar patterns to those found for the slurry agitated system: that is, a maximum metal leaching rate was achieved in the first 5 days until reaching a plateau on day 8, when leaching practically stopped. On the contrary, the behavior of Ni and Co is different, with leaching increasing even after 15 days. Although not studied, it can be suggested that those differences may be due to the different standard reduction potentials, geochemical partitioning in mine tailings, and electrochemical properties of the metal sulfides. The dissolution of each metal occurs due to redox reactions, and metal sulfides with lower reduction potentials would dissolve better [

25,

26].

To determine the total metal concentration in the soil, once the experiment was concluded the soil was separated into five portions to examine the metal concentration along the soil and to confirm the metal transport from the anode to the cathode. A consistent increasing concentration curve was observed for the majority of the metals studied (

Figure S1 in Supplementary Materials); it agrees with the transport direction caused in metals by the electrokinetic fluxes, i.e., electroosmosis and electromigration [

27]. Therefore, it can be concluded that the application of the electric field achieved the effective transport of the metals solubilized from the mine tailings to the cathode well, where they were removed; in addition, the precipitation of metals in the area close to the cathode was avoided because the acidity was maintained through correct pH control.

Figure 4 shows the final extraction efficiencies for the different metals after 15 days in all the treatments applied. It can be observed that using the BL medium led to higher extraction yields as compared to the reference tests. Most metals showed higher efficiencies in the EK-percolation treatments than those in the agitated slurry ones; only Zn had an opposite behavior, probably due to its high initial concentration and availability in the mine tailings. This result reinforces the interest to further explore the feasibility of EK-percolation through a more detailed analysis of the operating conditions in order to understand the advantages or disadvantages of the EK system compared to the agitated slurry one.

For the analysis of the operating conditions (T, pH, or electroosmotic flow) in the EK-percolation treatments, we will use data previously reported in a previous work by our research team whose objective was to study the influence of the voltage gradient [

15]. The pH was maintained at sufficiently acidic values in all the treatments, although it was easier for the slurry system (in which it was maintained at pH 2.1); for EK treatments, the pH ranged between 2.5 (at the beginning of the test) and approximately 0.5 (at the end). Regarding the temperature, it was maintained at 30 °C in the slurry system while in the EK treatments it rose to approximately 35 °C from day 5 to day 10, due to ohmic heating of the soil. This heating would be much greater if voltage gradients above 2 V cm

−1 (to accelerate the bioleaching) were used, which would be a clear disadvantage for the development of microorganisms that conduct conventional bioleaching; this was actually the reason why it was decided to use the BL medium for the EK-percolation tests. Similar redox potential values and an excess of Fe

3+ (the active species for metal solubilization) in both EK-percolation and agitated slurry treatments using the BL medium were observed. The availability of atmospheric oxygen was high in the agitated slurry system and therefore the acidophilic microorganisms grown in the BL medium could contribute, at least to a small extent, to the leaching effect; however, aeration of the in situ EK treatments was not possible, which means that the only microbiological contribution to be considered in the bioleaching process was that carried out in the previous step of generating the BL medium.

The two main differences between the two types of treatment were the ratio of leaching medium to solids (mL g−1) and the hydrodynamics of the systems. After 15 days, the slurry system used a total of 100 mL of BL medium per gram of tailings, while the EK treatment used only 0.44 mL per gram (the total volume of BL medium, 1300 mL, was added as an anolyte as the electroosmotic flow through the cathode well was withdrawn). These data would represent a large water saving and a significant cost reduction in the generation of the BL medium in the case of the EK system. Regarding hydrodynamics, the AS treatment used 150 rpm (corresponding to a Reynolds number of approximately 6 × 103) while the EK treatment slowly transported the water by electroosmosis without the need for agitation (approximately 1 cm per day, with a Reynolds number of approximately 2 × 10−3). These results indicate the effectiveness of EK-percolation in terms of BL medium requirements, which is even more valuable when considering that the contact between the leaching medium and the mine tailings was much smaller than in the case of agitated slurry treatments.

3.2. Kinetic Analysis

In order to perform a comparative analysis of the kinetics in both treatments (AS and EK), the experimental leaching data for the different metals have been fitted to a simple mathematical model proposed in the literature [

8,

16]. Such kinetic modeling analysis is important to determine important kinetic features of bioleaching, such as the reaction time, reaction rate, or reaction favorability.

During leaching or bioleaching, oxidants such as H

+ and Fe

3+ react to extracted metal. This oxidation process can be controlled by one of the three following steps, with the slowest step typically being the rate-controlling process: (i) formation of the product layer (around the material), which creates resistance to the diffusion of oxidants to the material’s surface (diffusion-controlled process); (ii) reaction of the oxidants at the particle surface, which will be slower than their diffusion when no product layer is formed or it does not affect the free movement of oxidants to the particles’ surface (chemically controlled process); and (iii) liquid film diffusion, in which the leaching solution may resist the transport of oxidants to the surface, controlling the overall observed rate. Srichandan et al. [

8] suggest that considering film diffusion as the controlling step may not be prudent; instead, the chemical and product layer diffusion processes should be evaluated to determine the rate-controlling step. If the reaction rate is controlled by solid product layer diffusion, it can be described using the shrinking core model theory (Equation (1)). Conversely, if the leaching rate is controlled by a chemical reaction at the particle’s surface, Equation (2) is used to represent leaching kinetics [

16]. Both equations describe a linear plot with gradient k, where Ft represents the fraction of metal mobilized at time t, calculated from the solubilization data and the initial total metal concentration in tailings. It was assumed that the concentration of the leaching agent (Fe

3+) was high enough to not be a limiting reagent, which is a necessary condition for using these two conventional models [

16].

Figure 5 shows the fitting of experimental data to Equations (1) and (2) in the case of Mn leaching (Mn is used as an example, and the following discussion applies to other metals as well). Lizama [

28] proposed that plotting these equations in a bioleaching process reveals two stages: the first stage shows a progressive increase in the slope (k), while the second stage exhibits linear behavior with a constant and maximum k value. The first stage would correspond to an initial microbial colonization or activation phase, during which an acidophilic microbial biofilm is forming. In the second stage, the biofilm would be fully developed, colonization is complete, and the leaching rate reaches its maximum and remains constant, depending on the availability of the mineral surface area. In the present work, the first stage was not considered to occur for obvious reasons: leaching was induced by the addition of chemical oxidants in the BL medium and, therefore, the microbiological contribution may be considered negligible.

Figure 5 shows that the slope of the straight lines (k) is consistently higher when using the BL medium, aligning with the results presented in

Section 3.1. The values of k obtained for all metals are displayed in

Figure 6, where only the values for the treatments using the BL medium are plotted for simplicity. Previous studies [

16] have used correlation coefficients (R

2) to differentiate which model best fits the experimental data, suggesting that the primary controlling mechanism would correspond to the model with the best mathematical correlation. In the present work, the differences in R

2 are minimal (which could be due to the small number of experimental data used in the mathematical fitting), making it difficult to definitively identify the rate-controlling mechanism.

Figure 6 shows that the kinetic constants obtained for the EK treatments are higher than those obtained for the AS ones, for all metals except Zn and Mn (with a very small difference for Mn). These results are consistent with those shown in

Figure 4. Additionally, the k values range approximately between 10

−3 and 10

−2 d

−1, whereas Lizama [

28] reported k values for bioleaching in the range 10

−4–10

−3 d

−1. It can be suggested that the values obtained in this study are somewhat higher because chemical leaching has been used, which may be faster than biological leaching.

Overall, the efficiency and rate of the EK-percolation treatments do not appear to be lower than those of the classical agitated slurry system, suggesting a promising potential for the viability of electrokinetic-assisted percolation. Schippers et al. [

29] observed similar sphalerite bioleaching rates when comparing shake flasks to percolators; they attributed these similar rates to the comparable available surface area in both systems, indicating that the kinetics of bioleaching were controlled by the solid particle surface area. A similar situation could be considered in the present work.

Additional factors should be considered to evaluate the potential advantages of using EK-percolation. Electrokinetics is particularly recommended for water percolation in low-permeability soils, as it facilitates water flow through mineral ores with small particle sizes. This results in a high availability of particle surface area and increased reaction rates. Bakthi et al. [

30] reported limitations in vertical percolation flow by gravity, necessitating the agglomeration of fine-grained ore samples to facilitate percolation. Additionally, water consumption in EK-percolation and the requirements of the BL medium appear to be very low compared to conventional agitated systems. However, pH control in the soil zone near the cathode compartment is crucial to remove leached metals and prevent metal precipitation. Furthermore, the rise in temperature due to ohmic heating when using higher voltage gradients can lead to significant energy losses. Beyond the current analysis, which focuses on the comparative influence of various factors on the rate and efficiency of both systems, future pilot and full-scale studies should consider other factors such as the cost of excavation, transport, soil washing and separation, or electricity consumption.