1. Introduction

Eggs are an excellent source of nutritional and biologically active substances—proteins and lipids, as well as all essential amino acids. They are defined as the cheapest animal source of protein [1]. Apart from being nutritious, eggs also have functional properties, such as foaming, emulsifying, and gelling ability [2].

Approximately 30% of the egg supply in developed countries is processed into various processed products and not sold as shell eggs [3]. This percentage reaches up to 50% in some countries of the European Union [4]. Egg products are eggs that have been processed and packaged in a convenient form. Some examples of egg products include dried, liquid, or frozen egg white, yolk, or whole egg. These egg products are used in the food industry after heat treatment to remove bacterial contamination [5,6]. Industrialized production of egg products offers economic benefits, but a significant amount of waste is generated [7].

Under the European Commission’s proposals, the circular economy package will aim to minimize waste so that when a product reaches the end of its life, its materials remain in the economy as much as possible. Therefore, what was previously considered “waste” becomes a valuable resource [8]. The 3R principles (reduce, reuse, and recycle) are at the heart of the “circular economy” [9].

Food waste is one of the important factors for the carbon footprint. The consequences of increasing greenhouse gas emissions are climate change, water scarcity, pollution, soil erosion, and a reduction in biodiversity above and below ground. The treatment of food waste through various sustainable methods is of primary importance to reduce the anthropogenic impact on nature [10]. The wastes in the production of egg products are eggshell ~70%, eggshell membrane ~10–15% (solid waste), and adherent (technical) egg white ~10–15% (liquid waste) [11]. It can be estimated that at least 7,894,962 t of egg processing waste is produced annually worldwide, of which 777,000 t is low in the Union [12]. According to European legislation, waste from the processing of eggs with animal by-products is category 3, and the legislation allows it to be processed into feed [13]. Feed materials from egg products are present in the EU feed materials catalog [14].

The conversion of food waste into animal feed is preferable to composting and anaerobic digestion for biogas production or disposal in landfills [15]. Technical albumen (TA) is a viable animal feed after proper processing due to its excellent amino acid profile, energy content, and presence of antimicrobial proteins, but it has received little attention from the industry [16]. The proteins contained in the technical egg white are identical to those of the egg white proteins [12]. An example of protein utilization from this waste product is application in feed for broiler chickens [17] and weanling pigs [18]. Egg waste spray drying technology is a common method of producing animal feed from this type of waste. According to Banožić et al., spray drying is used to process egg by-products into feed, but the biggest disadvantage of this type of processing is the high investment costs [19].

In our previous research, we found that acid–thermal coagulation is a possible alternative way to treat liquid waste from egg processing. In our preliminary study, we used four different types of acids. From them, the most suitable acids for pH correction are citric acid (CA) and phosphoric acid (PA), which showed the best values of the production indicators yield and pressing efficiency [20]. In this study, we characterized the raw TA and the final product from it. We evaluate the most suitable pretreatment to reduce moisture before drying in order to reduce the cost and heat impact on dry egg products. The initial characteristics of produced dried egg products from TA will be evaluated, as well as their changes during storage. We describe and compare the obtained characteristics of the finished product

4. Discussion

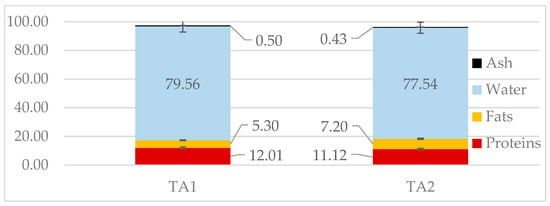

Waste from egg processing plants constitutes a significant amount of the food processing industry. The second in quantity of these wastes is liquid TA waste [12]. Egg waste products are animal by-products (ABP) category 3. The management of these products, due to safety reasons, is strictly regulated by European legislation. The ABP regulations set out rules for the collection, transport, storage, handling, processing and marketing, import, export, and transit of crude ABPs and products derived from them, which are among the strictest in the world. Feed costs are the largest cost of farming livestock in Europe, mainly due to the need to use imported protein ingredients (soybean and fishmeal), and can be reduced by investing in other protein-rich sources. Also, egg products circumvent the prohibitions of Regulation 999/2001 [40] on feeding farm animals with feed containing sources of animal origin. Feed ingredients from egg waste products can be fed to all categories of animals, including ruminants. [41]. European legislation allows the use of ABP category 3 as animal feed, and TA is particularly suitable due to its chemical composition (Figure 1). It contains a significant amount of water but also nutrients—mainly proteins and fats.

It is known that all the fat in eggs is found in the yolk. During the mechanical breaking of eggs in egg processing plants, the vitelline membrane of the yolk is broken, and part of it falls into the TA. The different amounts of fat in the samples may be due to the different eggs used as raw material. Other factors that have an influence are the speed of breaking the temperature of the eggs. The fat content of this product varies and cannot be predicted. The established amino acid composition confirms the statement that the nutritional completeness of the TA is no less than that of egg white intended for human consumption [42]. The pollution of TA with yolk during processing is the most logical explanation for the increase in the yellow component of the color (b*).

In the context of the circular economy, this waste should be considered as raw material for animal feed after appropriate processing meets the feed criteria [8]. The raw TA has an unstable composition and is microbiologically inoculated but does not contain the pathogenic Salmonella spp. The high microbial contamination is a consequence of the method of obtaining this product by crushing the eggshells. For this reason, ref. [43] prohibits its use for human consumption. Our microbiological results of the raw product for TPC, coliforms, and Enterobacteriaceae indicators confirm that TA does not meet the criteria and should be used after heat treatment (Table 3). In order for ABPs to be used, they must first be processed to meet the microbiological criteria specified in Regulation 142/2011 [21]. A method based on acid–thermal coagulation is suitable for processing this material. Heat treatment and subsequent drying of the product ensure a reduction of the microbial population. In the final product, after a month of storage, bacteria from the family Enterobacteriaceae, coliforms, and E. coli are not detected, and TPC has decreased to an acceptable level (Table 7).

Our results show that in the pretreatment before drying, the product is partially dehydrated. In the pressing process, the product loses up to 45% of its water content. This treatment facilitates drying because it starts from a lower moisture level. In addition, due to the low energy costs, the drying time and the impact of high temperatures on the product are reduced. This, in turn, reduces the formation of unwanted compounds that can be monitored by measuring the color characteristics.

The best yields are obtained using CA 97.79%; this value indicates that the dry matter losses during the whole processing process for this sample are about 2.2%. The dry matter losses in this method of processing liquid egg processing waste are in the serum obtained during pressing. This serum contains varying amounts of non-coagulated soluble proteins and fats. Preliminary degreasing of the product does not lead to improvement of the production parameters. The dry end product contains over 46% protein and about 33% fat. These values are close to the stated protein and fat content of dry egg feed materials of 50.9% and 31.1%, respectively [44]. Also close are the values for protein and fat processed differently reported in the study (Figure 4). It can be concluded that the raw material and the type of processing do not have a significant impact on the fat and protein content of the final product. Norberg et al. and Song et al. also investigated the amino acid profile of spray-dried ABPs from eggs [44,45]. The results of the authors for the presence of amino acids in these products differ significantly from each other. Our repeated results for amino acid content also differed significantly for some amino acids. With these data, we can state that the amino acid profile of dry egg products is different depending on the raw material and the method of processing. The non-constant amino acid composition of the product can create difficulties in its dosing in feed production.

Our final products had low moisture and low water activity. These low values contribute to the easy storage and transport of the obtained product [33]. The increase in water binding capacity during the storage period is a potential result due to the observed moisture loss of the investigated samples. All samples were found to be characterized by about 3–4% moisture at the end of storage, which was significantly lower (p ≤ 0.05) than the initial one (Figure 1). A potential explanation is that samples containing less moisture retain more water upon rehydration to compensate for losses during storage. Water binding capacity is the ability of a material to retain free water in its structure. It depends on the physical and chemical properties of the specific material, including the structure of proteins and polymers. This is important for food, cosmetics, and other materials where humidity plays a key role. Water activity (aw) is a measure of the availability of free water, which can participate in various microbiological processes and chemical reactions in a given system. It is expressed as a ratio between the partial pressure of water in the system and the partial pressure of pure water at the same temperature [33].

The color brightness L* of dry egg products is directly related to the initial characteristics of the raw material and the applied heat treatment. The reported decrease in L* values may be a consequence of the Maillard reactions that took place during the drying process at high temperatures [32]. This type of reaction is also known as non-enzymatic browning of foods that have a high protein content. Color characteristic values can also be an indicator of changes in the product during drying. In the raw product, the L* value was around 66 (Table 2), but after drying, the value reached over 80 in three of the samples (Table 5). As a new method of processing this raw material, further research can be directed towards process optimization and reduction of pressing losses. It is also reasonable to monitor the chemical parameters during a longer period of storage and the factors affecting the AA profile in order to create a predictable product composition.

Changes in the lipid and protein fraction occurred during storage, but the values obtained for TBARS and PC were low. Some authors reported an increase in lipid oxidation and formation of TBARS in dried egg products with very low water activity (aw < 0.300) [32]. In our case, we cannot conclude such a correlation. It is necessary to test these indicators for a longer period of storage since, after drying, the product is durable from a microbiological point of view, but the processes of changes in the lipid and protein fractions continue. These changes can lead to unacceptable changes in organoleptic indicators and the formation of a significant number of toxic substances [46].

Last but not least, the microbial status of the dried egg products from TA is stable during storage. This is most likely due to both the thermal treatment of the raw material and also the low moisture content and water activity. The absence of Salmonella spp. is a clear statement for the safety of the final products [47].

Source link

Plamen Saraliev www.mdpi.com