1. Introduction

Finally, this work presents a novel trigeneration system for the simultaneous production of water, cooling, and electric power, integrating a hybrid MSF/MED desalination and cooling subsystem. This system proposes the energetic and mass integration of two thermal desalination technologies: Multi Stage Flash (MSF) with 8 stages and Multi Effect Distillation (MED) with 6 effects. The technological contribution of this hybrid MSF/MED system lies in the extension of the operating range, with a top brine temperature (TBT) of 68 °C and a bottom brine temperature (BBT) of 4 °C in the sixth effect. The elimination of preheaters in the MED section allows all generated steam to be used for brine evaporation in the subsequent effects. Additionally, an electrical expansion-generation subsystem is integrated, which extracts a fraction of the mass flow from the first flash stage to generate electricity and meet the system’s electrical demand. The expanded steam is reinserted into the first effect of the MED section, increasing capacity and efficiency in both desalination and cooling. Furthermore, a condensation process using two barometric ejectocondensers is employed instead of a conventional condenser, facilitating the extraction and adaptation of cold steam to produce desalinated water. The 4 °C product water stream from the final MED effect is then used to generate a cooling effect, further enhancing system efficiency.

The proposed trigeneration system introduces an innovative technology that simultaneously produces desalinated water, cooling, and electrical power. Key innovations include the elimination of seawater preheaters in the MED section, improving overall system efficiency, and the integration of components that optimize energy use. This configuration provides a sustainable approach to meeting water, cooling, and electricity demands simultaneously.

2. System Description

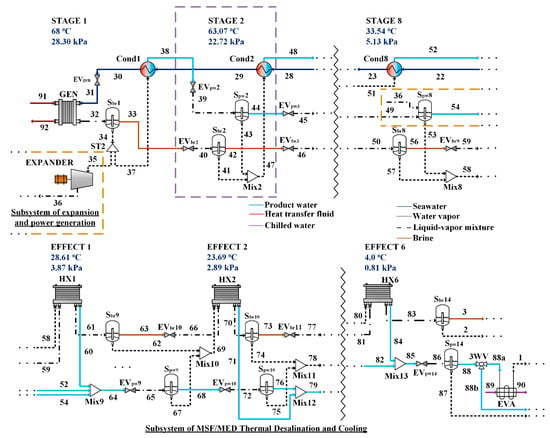

The operation of the hybrid MSF/MED thermal desalination and cooling subsystem begins when the seawater stream (18b) is drawn from the Seawater Tank and pressurized to the transport pressure (3 to 5 bar) by the hydraulic pump (PSW2), exiting as stream (22). This is introduced to the condenser (Cond8), where it absorbs the latent heat of condensation of the water vapor stream (51), preheating in the process. Then, the seawater stream (23) passes through the condensers of the subsequent stages, gradually increasing its temperature by acquiring the latent heat of condensation. This process continues until it reaches the maximum preheating temperature (65.5 °C) in the condenser (Cond1), exiting as the seawater stream (30). Subsequently, it is introduced to the expansion valve (EVgen), where a sudden pressure drop is performed until it reaches the saturation pressure of the TBT of the MSF/MED hybrid desalination subsystem. The stream (31) then enters the generator, where it receives both sensible and latent heat from the heat transfer fluid, which can come either from the solar collector field (stream 91) or from another thermal source. At the generator (GEN) outlet, the seawater stream (32) is in a two-phase (liquid-vapor) state and is introduced into a liquid-vapor separation chamber (SBr1), where it is divided into two streams: the concentrated brine (33) and the vapor (34). The concentrated brine stream (33) is directed to the second flash distillation stage, where it is introduced into the expansion valve (EVBr2). This valve suddenly reduces the pressure to the operating condition of stage 2, causing the flashing effect and steam generation, which leads to the concentrated brine stream (40) being in two phases. In turn, the mass flow of the water vapor stream (34) is divided by the splitter (ST2) which directs a fraction of the mass flow to the expander (stream 35) and another to the condenser (Cond1) (stream 37). The water vapor stream (37) is completely condensed in the condenser (Cond1) and then directed to the second flash distillation stage, where it is introduced into an expansion valve (EVPW2) to suddenly reduce its pressure to the operating condition of stage 2, which causes the flashing effect and vapor generation, resulting in a two-phase product water stream (39). The flashing vapors generated by the sudden pressure drop in the brine and product water of stage 2, are directed to their respective liquid-vapor separators (SPW2) and (SBr2), and then mixed in the mixer (Mix2) and subsequently condensed in the condenser (Cond2). The liquid streams of brine and product water are directed to the expansion valves of the next stage (EVBr3) and (EVPW3) to repeat this process successively until the eighth flash distillation stage.

At the end of the eighth flash distillation stage, multiple distillation effects (MED) are initiated. MED effects involve the use of heat exchangers for the evaporation or release of water from brine streams, using the water vapor generated in a previous effect. In addition, two liquid-vapor separators are used in each effect; one for the product water and one for the concentrated brine, as well as two expansion valves. It is important to note that, in the multiple distillation effects, due to their respective operating temperatures, seawater preheating equipment cannot be used, which is characteristic of high vacuum systems. The water vapor that activates the MED section is obtained from the sudden expansion of the brine and product water from stage eight of the MSF section, where the two-phase product water stream (49) enters the liquid-vapor separator (SPW8) and splits into two: a vapor stream (53) and a product water stream (54).

The two-phase concentrated brine stream (50) enters the liquid-vapor separator (SBr8), where it is divided into a vapor stream (57) and a brine stream (56). The streams (53) and (57) are mixed in the mixer (Mix8) and exit as stream (58), which will activate the first MED effect by releasing its latent heat and condensing in the heat exchanger (HX1), leaving as stream (60).

The concentrated brine stream (56) enters the expansion valve (EVBr9), where this valve suddenly reduces the pressure to the operating conditions of effect 1, in addition to causing a flashing effect and the generation of steam, this pressure reduction also leads to a decrease in the temperature of the stream (59). The two-phase stream (59) is directed to the heat exchanger (HX1) where it receives the latent heat of condensation from the steam streams (58). This heat exchange is possible since the aforementioned vapor stream (stream 58) are at a higher temperature than the two-phase brine stream (59), maintaining a minimum approach temperature of (∆Tmin = 2.5 °C) to carry out the heat transfer.

After exiting the condenser (Cond8), the product water stream (52) is directed to the mixer (Mix9) together with the product water streams (54) and (60), exiting as the product water stream (64). The product water stream (64) enters the expansion valve (EVPW9), where the pressure is suddenly reduced to effect 1 operating conditions. Simultaneously, the two-phase concentrated brine stream (61) is directed into the liquid-vapor separator (SBr9) and splits into two: a vapor stream (62) and a concentrated brine stream (63), where the latter enters the expansion valve (EVBr10), where the pressure is suddenly reduced to the operating conditions of effect 2. This process is repeated sequentially until the sixth multiple distillation effect is reached. The expansion and power generation subsystem begins by receiving a fraction of the vapor mass flow (stream 35) from the brine vapor-liquid separator (SBr1). The vapor stream (35) is then introduced into the volumetric expander, where it is drawn in and admitted into an expansion chamber. During this expansion process, the specific volume of the vapor increases (v36 > v35), resulting in a simultaneous decrease of its pressure and temperature. The study of the expansion subsystem details two different modes of operation, characterized by working with different discharge pressures. In mode 1, the specific volume of the stream (35) is expanded to reach the operating pressure of MED effect 1, while in mode 2 it is expanded to reach the operating pressure of MED effect 6. Finally, the subsystem concludes with the insertion of the two-phase stream (36) in the liquid-product water vapor separator corresponding to the effect in which the outlet pressure of the volumetric expander coincides. By reinserting the two-phase stream (36), the vapor mass flow of that stream is combined with the vapor mass flow fraction of the two-phase stream (65) within the vapor-liquid separator (SPW9). This results in an increase in the mass flow in the vapor stream (67) and, consequently, in a higher heat transfer within the exchanger (HX2), which causes a higher generation of water as vapor from the two-phase sea brine stream (66). The described phenomenon is repeated successively in the subsequent MED effects, which increases the product water generation and cooling capacity of the proposed trigeneration system.

It is worth mentioning that the kinetic energy of the fluid (stream 35) is extracted by the expansion process and converted into mechanical work. This mechanical work is transferred to the rotary motion by the rotor to the shaft, then the shaft work is channeled to an electric generator for final conversion into usable electrical energy. The electrical energy produced by the expander is used for the self-consumption of the proposed system.

After leaving the sixth effect, the product water stream (84) is mixed in the mixer (Mix13) with the accumulated product water stream (82) from previous distillation stages and effects, resulting in the final product water stream (85). The latter passes to a 3-way valve (3WV), whose main function is to control the direction and/or division of the product water stream (85). It is important to note that the product water stream (88a) is used as the cooling fluid because it is in a saturated state, with a temperature of 4 °C and a pressure of 0.81 kPa. The supply of the cooling fluid to the (stream 88a) is conditioned by the 3-way valve (3WV), allowing its partial or total use, depending on the cooling needs required by the user. On the other hand, the product water stream (88b) is directed to a barometric column (BC2) where its pressure is increased and discharged into the product water tank. The vapor streams (1) and (2) at low temperature and vacuum pressure are conducted to the ejector condenser (EJ1) for condensation by pressure increase.

Inside the mixing chamber of the ejector, a shock wave is produced due to the deceleration of the mixed stream, resulting in an increase in pressure and temperature of the mixture, all as a result of the transport phenomena mentioned above. Subsequently, the mixture of motive and suctioned fluid (also called primary and secondary) enters the diffuser, where, by increasing the cross-sectional area of the ejector, its velocity decreases, causing a pressure increase and thus achieving total condensation of the water vapor. Finally, the condensed mixture (10 and 15) is directed towards the barometric columns (BC1 and BC3) because it is under vacuum pressure, before being deposited in the product water storage tank at atmospheric pressure.

The ejectocondensation process causes a temperature increase in the mixed streams at the outlet of the ejector due to the transfer of condensation heat from the secondary fluid to the primary fluid. This increase in temperature causes energy accumulation in the product water storage tank, from which the motive fluid is extracted. To counteract the temperature increase, the heat exchangers (HXBrine) and (HXSW) are used in their respective condensation circuits. The heat exchanger (HXBrine) uses the concentrated brine stream (3) as a cold stream (4 °C), which makes it possible to reduce the temperature of the motive fluid stream (9) to 9 °C. On the other hand, the heat exchanger (HXSW) uses the seawater stream (19) as the cold stream (25 °C), allowing a temperature of the motive fluid stream (14) of 28.5 °C. The two-phase brine stream (4) is split into two in the vapor-liquid separator (SBr15). The concentrated brine stream (17) is directed to the barometric column (BC4), to increase its pressure and be subsequently deposited in the brine dissolution tank, where it joins with the seawater stream (20). The steam stream (5) enters the flow splitter (ST1) to control the steam mass flow to be condensed in both ejectocondensers. The ejectocondenser (EJ1) condenses the vapor stream (6), which consists of the sum of the vapors coming from the evaporator (1), the sixth effect (2) and the vapor stream (5b). On the other hand, the ejectocondenser (EJ2) is in charge of condensing the remaining vapor (88) that was not introduced in the first ejectocondenser.

Main Characteristics of the System

The system combines an 8 stage Multi Stage Flash (MSF) process and a 6 effect Multiple Effect Distillation (MED) process, operating under high vacuum conditions. With MSF pressures ranging from 28.3 to 5.1 kPa and MED pressures from 3.8 to 0.8 kPa, the system enhances desalination efficiency and expands operational capabilities compared to conventional designs.

Two two-phase ejectors operating at different temperatures extract and condense low-temperature steam from the final MED effects, improving energy recovery and efficiency. The concentrated brine stream acts as a heat dissipating fluid in the first ejectocondensation circuit, further enhancing water production.

The system eliminates seawater preheaters, as the absence of a temperature gradient allows direct use of generated steam for brine evaporation in subsequent effects. This simplifies the system, reduces heat losses, and increases water production capacity.

An expander-generator subsystem uses stage 1 flash steam to produce electrical power, with the expanded steam reintroduced into the MED effects. This dual-use of steam optimizes energy integration and supports the system’s trigeneration capabilities.

The final product water, in a saturated state at 4 °C, is used as a cooling fluid for the evaporator, minimizing the need for external cooling resources and increasing system efficiency.

The system incorporates control measures to limit steam generation and prevent calcium sulfate (CaSO4) precipitation, ensuring operational stability and maintaining long-term system reliability.

5. Analysis and Discussion of Results

The parametric study presented in this work on the proposed trigeneration system is divided into two parts: the analysis of the system’s behavior in cogeneration mode and its behavior in trigeneration mode.

5.1. Operational Study of the System in Cogeneration Mode

To operate in cogeneration mode, cooling production is eliminated in the MSF/MED hybrid thermal desalination subsystem under high vacuum conditions. This is achieved through the control of the 3-way valve (3WV), which diverts the condensed product water stream (88), preventing its entry into the evaporator (EVA) and thereby stopping the generation of the cooling effect in the system. The bypassed condensed product water stream (88b) is directed to the barometric column (BC2). The function of this column is to maintain the hydraulic vacuum seal of the system and increase the pressure to atmospheric levels, preparing the water for storage in the product water tank.

5.2. Operational Performance Results of the MSF/MED Thermal Desalination Subsystem Under High Vacuum in Cogeneration/Trigeneration Modes

In the MSF section, heat transfer occurs only in the first stage due to the presence of the generator, which produces the steam necessary to reach the preheating temperature. The excess steam generated when operating above Qgen = 50 kW is used for the expander to produce electrical energy. As activation heat increases, the heat transferred for seawater preheating decreases, since the required heat is supplied by the mixture of flashed vapors from the product water and brine within the MSF. More steam generated in the generator reduces the brine flow to the second stage, decreasing the amount of flashed steam and, consequently, the heat transfer for preheating. This results in an increased steam flow to the condenser (Cond1) to achieve the maximum preheat temperature.

After the MSF section, the flashed vapors are no longer used to preheat the seawater due to the lack of a minimum temperature (ΔTmin = 2.5 °C) difference Instead, they are used to boil off the brine in the first effect of the MED section, gradually increasing heat transfer. Additionally, the reinsertion of steam expanded by the expander into the eighth stage of the MSF increases the mass of available steam, enhancing heat transfer in the MED section and creating a cascading effect throughout the other effects in the system.

By increasing the activation heat, more steam is generated in the generator. The excess steam produced, which is not required to feed the Condenser (Cond1) in stage 1, is used as a working fluid for the expander and is reintroduced in the eighth stage. The MED section is activated by utilizing the expanded steam from the expander, along with the vapors generated by the flashing of product water and the brine flow from the eighth stage. This creates a cascading effect, where the vapors generated by flashing are no longer used for preheating, but instead for boiling, allowing more water to be extracted from the brine stream as it passes through the effects. The increase in heat added to the generator leads to an increase in product water production capacity and, consequently, to a higher cooling capacity of the system in trigeneration operation.

5.3. Operational Performance Results of Subsystems: Product Water Extraction, Adequacy, and Cooling of the Motive Fluid in Cogeneration Mode

5.4. Overall Operating Performance Results in Cogenerative Mode

5.5. Operational Study of the System in Trigenerative Mode

To operate the proposed system in trigeneration mode, the condensed product water stream (84) exits the sixth effect in a saturated state at 4 °C and 0.81 kPa. This stream is directed to a three-way valve (3WV) that regulates its flow based on cooling demand. When cooling is required, the valve redirects stream (88a) to the evaporator (EVA), where its low temperature efficiently absorbs heat to produce the cooling effect. If cooling is not needed, the valve diverts stream (88b) to a barometric column (BC2), where it undergoes a controlled pressure increase before being discharged into a product water tank. Additionally, low-temperature vapor streams (1) and (2) from earlier stages are processed in the ejectocondenser (EJ1), where they mix with a high-pressure driving fluid. This process condenses the vapor, releasing latent heat and maintaining vacuum conditions, while the condensed fluid is directed to BC2. By combining chilled product water and vapor condensation via the ejector, the system achieves efficient and flexible cooling production, optimizing its performance in trigeneration mode.

This trigeneration operation, involving the simultaneous production of product water, cooling, and electrical energy, has a direct impact on all subsystems, particularly in the cooling of the motive fluid and brine dilution. Power generation requires the production of additional steam in the generator, which is used as the working fluid to feed the expander. Subsequently, the expanded steam at the expander outlet is reinserted into the vapor-liquid separator (SPW9), increasing product water production and cooling capacity, as a greater mass flow of steam is available for boiling the concentrated brine stream (66) entering the heat exchanger (HX2). This leads to a higher concentration of brine at the outlet of the sixth effect. These factors result in a reduction of the maximum limit of the reinjected steam mass flow percentage and a decrease in the final concentration of the brine entering the brine dilution tank.

5.6. Operational Performance Results of Subsystems: Product Water Extraction, Adequacy, and Cooling of the Motive Fluid in Trigeneration Mode

Additionally, the dissipation of condensation heat from the motive fluid by the saturated brine stream (stream 3) causes this stream to enter the saturation region, releasing water vapor and resulting in a higher concentration. The brine concentration at the outlet of the heat exchanger (HXBrine) shows an average increase of 203.01% compared to the concentration at the outlet of effect 6, exceeding the limiting concentration of 350.00 ppm when operating at QQgen = 350 kW, with a reported concentration of 386.959 ppm.

Furthermore, heat transfer in the heat exchanger (HXBrine) and the secondary flow (FsEJ1) tend to decrease due to the reduction in brine flow, resulting in a diminished capacity to remove condensation heat. This reduces the condensing capacity of the ejectocondenser (EJ1) from 0.1758 to 0.0869 kg/s, directing the remaining cold vapor to the second ejectocondenser (EJ2).

The increase in secondary flow (SfEJ2) requires a higher motive flow to achieve condensation, leading to an average increase of 17.86% in the electrical demand of the hydraulic equipment (PPW2). Conversely, the reduction in secondary flow (SfEJ1) results in an average decrease of 24.9% in the electrical demand of the hydraulic equipment (PPW1). Additionally, heat exchange follows the trends of both secondary and motive flows. As mentioned, condensing a larger amount of steam requires a higher motive flow, resulting in increased heat transfer in the heat exchanger to remove the condensation heat generated in the ejection-condensation process. The heat transfer in the heat exchanger (HXBrine) decreases from 1974.25 kW to 459.35 kW, while the heat transfer in the heat exchanger (HXSea) increases from 979.02 kW to 2954 kW.

5.7. Overall Operating Performance Results in Trigenerational Mode

The power demand of the proposed system is primarily driven by the hydraulic pumping equipment in the product water extraction and adaptation subsystem. In trigeneration mode, the electrical demand increases due to the higher flow of motive fluid required for the condensation of the product water stream (88a) evaporated in the ejectocondensers (EJ1 and EJ2).

This is because the electrical generation provided by the expander is less than the increase in the electrical demand of the system’s hydraulic equipment, which is caused by the impact of the expanded steam on the MSF/MED thermal desalination subsystem operating at high vacuum, as well as the increase in cold steam mass flow from effect 6 and the evaporator. The system’s electrical demand increases to a maximum of 351.14 kW, but the power generated by the expander reduces the system’s overall electrical consumption by an average of 5.32%. Additionally, the self-consumption electrical coverage varies between 2.11% and 7.18%.

Although the product water capacity increases from 1128 to 1304 m3/day, this increase is not significant. The additional steam production in the generator leads to a rise in both water production and cooling capacity, increasing the power demand, which the expander fails to fully compensate. As a result, SEC indicator increases from 53.16 to 143.95 kWh/m3, reflecting higher energy consumption relative to the activation heat.

5.8. Operational Performance Results of the Ejectocondensation Process

A study based on the second law of thermodynamics was conducted on the barometric ejectocondensation process, with the objective of determining the operating parameters of the motive pressure for the hydraulic pumping equipment (PPW1 and PPW2). The study assumed constant thermodynamic properties for the secondary fluid, with a pressure of 0.804 kPa, temperature of 4 °C, and mass flow of 0.2167 kg/s. For the motive fluid, an initial mass flow rate of 130 kg/s was considered. However, as mentioned, the hydraulic pumping equipment features a flow variator that adjusts to ensure condensation.

5.9. General Comparison

5.9.1. Operating Mode Comparison

The technological system developed in this work exhibits a distinctive operating behavior in terms of water production and electrical demand, depending on the operation mode.

In trigeneration mode, the condensed water in the MED section is sent to the evaporator (EVA), where it changes phase to steam. This additional steam is directed to the ejectocondenser (EJ1) for condensation, increasing the motive flow (FmPW1) and heat dissipation in the heat exchanger (HXBrine). The saturated brine (stream 3) is further heated and separated in the liquid-vapor separator (SBr15). Water vapor extraction in trigeneration mode varies from 0.791 to 0.1915 kg/s, while in cogeneration mode it ranges from 0.211 to 0.099 kg/s. This process reduces the final brine flow (stream 17), enhancing the potential for valuable mineral extraction and achieving zero liquid discharge.

5.9.2. Literature-Based Operating Comparison

In terms of energy demand, the MSF/MED-HV system requires 150 kW of generator heat input (Qgen), 21.71% lower than the Qgen reported by La Torre et al. and 13.5% lower than that of López-Zavala et al., highlighting its improved thermal efficiency. However, the total power requirement for hydraulic pumps (Wpumps total) is higher (231.98 kW), primarily due to the dual barometric ejectocondensation process. Despite these demands, the system achieves superior global performance indicators, with a PRglobal of 6.99 and a COPglobal of 10.43, representing an improvement of 50.32% and 11.84%, respectively, compared to López-Zavala et al. system. These advances highlight the significant thermodynamic and operational efficiency of the proposed design.

6. Conclusions

This study presents a novel trigeneration system that simultaneously produces desalinated water, electrical energy, and cooling, addressing critical challenges related to water scarcity and energy demand in coastal regions. The system integrates hybrid MSF and MED technologies under high vacuum, coupled with ejector-condensation mechanisms and an expander-generator subsystem. These innovations enhance energy recovery, operational flexibility, and resource efficiency.

Simulation results using Aspen Plus demonstrated the system’s technical feasibility and superior performance across different operating modes. In trigeneration mode, the system achieved a RR of 80%, a PR of 17.81, and a cooling capacity of 1225 kW while producing 99,273.6 L/day of desalinated water. In cogeneration mode, the system achieved a PR of 12.06 and reduced electrical consumption by 12.03%, emphasizing its adaptability to seasonal and demand-based operational shifts.

Key innovations include the elimination of seawater preheaters in the MED section, which reduces heat losses and increases desalination capacity, and the use of barometric ejector condensers, which optimize steam utilization and cooling production. These features not only improve energy efficiency but also simplify system design, making it more cost-effective and scalable for real-world applications.

The proposed system demonstrates significant potential for mitigating water and energy challenges while promoting sustainability. Future research should focus on validating the system under experimental and field conditions, assessing its long-term reliability, and exploring opportunities for scaling up to meet larger community needs. Additionally, economic analysis and life-cycle assessments would provide deeper insights into the system’s commercial viability and environmental impact.

Source link

Francisco J. Caballero-Talamantes www.mdpi.com