3.3. Numerical Parametric Results

Following the validation of the damaged numerical cases, a parametric investigation was conducted using the parameters outlined in

Table 2. The analysis considered W-Type and WF-Type corrosion damage; the results are depicted in

Figure 8 and

Figure 9. For W-Type corrosion,

Figure 8 demonstrates that post-buckling strength remains unaffected until the corrosion length ratio (Lc/L0) reaches 0.5, corresponding to corrosion affecting half of the panel’s length. Beyond this point, a gradual reduction in post-buckling strength is observed. Conversely,

Figure 9 shows that WF-Type corrosion patterns exhibit negligible impact on post-buckling strength up to 40% of the panel’s length (WF40). However, corrosion exceeding this threshold results in a rotation of the inclination angle, resulting in a pronounced strength reduction which is attributed to a localized yield formed in the fracture point near the flange damage.

The post-buckling behavior for both corrosion patterns, along with experimental data for the WF50 case, is presented in

Figure 10. For W-Type corrosion, post-buckling strength starts to decline once corrosion progresses to half of the panel’s length L

HC/L

0 ≥ 50% due to the damage of the plastic hinge (Ct), located on the lower flange affecting the anchorage of the tension field.

In contrast, WF-Type corrosion shows a marked decline in strength beyond LHC/L0 ≥ 40%. The decline between 40% and 50% is abrupt and driven by the initiation of the localized yielding causing a hinge-like rotation of the inclination angle in the vicinity of the flange cut. The mechanisms underlying these reductions are further discussed in the subsequent section.

3.4. Mechanism of the Decline in Post-Buckling Strength

To explain the effect of corrosion on web panels, the out-of-plane deflection curve showing the mode of buckling for the Base case is presented in

Figure 11. It can be seen that the width of the tension field corresponds to the inflection points of the out-of-plane deflection curve. In an undamaged web panel, the width of the tension field can be theoretically determined based on Basler’s Equation (3) [

10].

here () is the inclination angle of the tension field as shown in the figure, (B) is the height of the web panel, and shows the panel’s aspect ratio and plastic hinge location relationship.

the Cc and Ct are the plastic hinge locations on the tension and compression flanges with () being the plastic bending moment of the upper and lower flanges, and () is the stress causing yield of the tension field [8].

- a.

W-Type

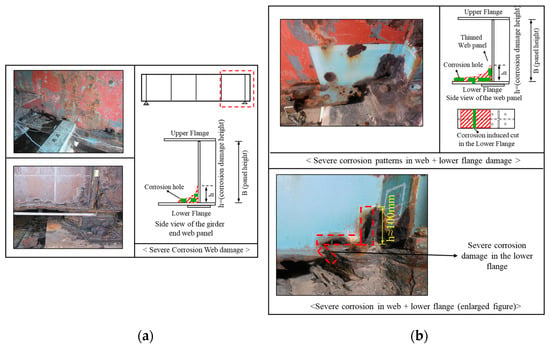

When corrosion progresses horizontally along the web’s longitudinal direction and disconnects the web from the lower flange (W-Type), the post-buckling strength begins to decline gradually, as illustrated in

Figure 8. This decline becomes significant once corrosion propagates beyond half the panel’s length. Prior to reaching this limit, the post-buckling strength remains unaffected due to the absence of a reduction in the tension field width (S), as described by the equation

.

However, as corrosion extends beyond half of the panel’s length, the post-buckling strength declines, as shown in

Figure 8. This decline is attributed to a reduction in the tension field width, which in this study is defined as the distance between the inflection points of the out-of-plane deflection curve. As described in Equation (3), the tension field width is directly related to the inclination angle of the tension field and the position of plastic hinges, as further detailed in Equation (3b). With the progression of corrosion that disconnects the web and lower flange, the tension field width decreases, causing the panel’s horizontal axis (

x-axis) to extend closer to the height of the web (

), as shown in

Figure 7. Consequently, the length of the plastic hinge (Ct) declines, as depicted in

Figure 12, resulting in a rotation of the tension field’s inclination angle, as shown in

Figure 13, as well as panel’s diagonal angle.

Figure 14 shows the rotation of the inclination angle as corrosion progresses as depicted in

Figure 13. From around L

HC/L

0 ≥ 50%, the plastic hinge on the lower flange gets damaged by corrosion. The tension field width gradually becomes narrower and due to the damaged (Ct), the inclination angle starts to rotate and decline. Therefore, due to the rotation of the tension field angle, its effective area reduces, and post-buckling strength declines. This behavior can be explained by the dependence of post-buckling strength on the tension field width, which, in turn, is influenced by the inclination angle and the plastic hinge length. Consequently, in W-Type corrosion cases, the post-buckling strength starts to decline as soon as the plastic hinges of the lower flange (Ct) are damaged by corrosion, resulting in rotation of the tension field inclination angle and a shift in the anchorage.

- b.

WF-Type

As illustrated in

Figure 9, when corrosion damages both the web and lower flange (WF-Type), the post-buckling strength remains relatively unaffected until the corrosion extends to 40% of the panel’s length. Starting at approximately L

HC/L

0 = 45%, a gradual decline in post-buckling strength is observed. However, at L

HC/L

0 = 50% the decline becomes more abrupt and severe. In W-Type corrosion cases, post-buckling strength remains stable until corrosion compromises the plastic hinge (Ct). However, as shown in

Figure 12, the plastic hinge length remains unaffected by WF-Type corrosion until the damage reaches half the panel’s length. Still, the tension field inclination angle is observed to decline starting from around L

HC/L

0 = 40%, becoming more pronounced from 45% as shown in

Figure 13, while the position of the plastic hinges on the lower flange (Ct) is observed to be unaffected. This is further confirmed in

Figure 15, where no significant changes in tension field action are observed up to L

HC/L

0 = 50%.

The decline in post-buckling strength starting from around L

HC/L

0 = 40% is primarily attributed to excessive damage to the web and the lower flange, which reduces the overall load-carrying capacity of the panel. Although the plastic hinge in the lower flange remains unaffected at this stage, the localized yielding of the web in the vicinity of the flange damage, shown in

Figure 15, causes an abrupt rotation of the tension field inclination angle, as shown in

Figure 13. Hinge-like behavior results in the decline of post-buckling strength, as shown in

Figure 16a. Excessive damage to both the web and lower flange contributes to the decline in post-buckling strength and is marked as Point 1 in

Figure 16a. At Point 2, which represents the peak strength, the rotation in the fracture point formed in the web in the vicinity of the flange cut, results in a rotation in the inclination angle causing a decline in strength, as indicated at Point 3. A comparison of the von Mises stress contours for the Base case and the WF50 corrosion case in

Figure 16c highlights the underdeveloped tension field and the location of the localized yielding of the web.

In WF-Type corrosion cases, the decline in post-buckling strength becomes more pronounced when the corrosion extends beyond LHC/L0 ≥ 40%. The damage to the lower flange leads to localized yielding at the fracture point in the vicinity of flange damage, resulting in a hinge-like rotation. This rotation results in altering the inclination angle, resulting in a reduction of the effective tension field area and, consequently, a decline in post-buckling strength.

As the current study has studied the effect of severe corrosion over steel girder ends, maintenance possibility and repair will be investigated as a part of future work.