1.1. Research Background

Elevators are a fundamental feature in buildings, serving as a crucial element of connection within different floors. Elevators not only facilitate vertical movement but also determine the accessibility and functionality of a building, impacting the flow of people and goods across multiple floors. Elevator technology has been essential for developing multi-story buildings, overcoming height limitations related to comfort and practicality [

1]. By optimizing space and improving efficiency, elevators have transformed urban landscapes, making it possible to house more people and businesses in a smaller footprint and significantly shaping the way individuals experience and interact with urban environments.

Elevators are mass-produced yet highly customizable products. As of 2024, estimates suggest that there are about 14 million elevators in the world [

2], with China having the highest number. In addition, before the current real estate crisis, the annual installation rate of new elevators approached 1 million. In comparison, Italy and Spain, the second- and third-largest countries by number of elevators, have approximately 1 million each with new installations ranging in the 8 k–12 k figure per year [

3].

These numbers are the consequence of estimations available within the industry by comparing different sources. Unlike cars, elevators are unregistered items in almost all countries, and consequently, there are no complete inventories of the number of installed elevators, and how many are still in operation or have been decommissioned.

As mass-produced products, certain design elements are standardized, yet it remains crucial for designers to carefully integrate these systems into the building’s architectural and functional framework. This involves considering not only practical aspects but also ergonomic, aesthetic, and safety features that contribute to the overall coherence and operational performance of the building.

Boesso [

4] suggested that the elevator car should at least have a modern appearance, given that people tend to trust older-looking elevators less, as they associate them with a higher likelihood of entrapments or accidents. There have been occasional reports of elevator accidents or malfunctions in every country, which can contribute to public safety concerns. Incidents like breakdowns, getting stuck between floors, or door malfunctions may heighten anxiety among users [

5]. This is directly connected to the “elevator phobia” [

6], a persistent fear of elevators that may stem from a fear of heights (acrophobia) and enclosed spaces (claustrophobia) and that is often associated with panic symptoms [

4].

Elevators have been recognized as essential vertical transportation systems and as key in facilitating access, particularly for individuals with varying mobility needs. Marshall et al. [

7] emphasize that elevators are integral for designing inclusive and adaptable spaces, ensuring independent and safe navigation in buildings for all users. However, the self-perceived safety of elevators can be a significant concern for some individuals. A previous study by the authors [

8] found that nearly half of the deaf and hard-of-hearing individuals who responded to a questionnaire perceived elevator use as unsafe. This sense of insecurity was primarily linked to the risk of getting stuck during an emergency stop and the inability to communicate with the outside.

Safety considerations have also been a focal point of studies analyzing elevator-related accidents and proposing improvements in safety management. Research by Lee et al. [

9] reviewed elevator accident cases to strengthen safety management practices, emphasizing the need for enhanced design and maintenance protocols.

A Chinese study [

10] examined factors influencing elevator comfort, including operational noise, stability, interior conditions, and ventilation systems. It also discussed integrating sensors to monitor the indoor environment of passenger elevators, aiming to enhance both safety and comfort levels.

Ergonomic considerations in elevator design are vital for promoting comfort, reducing physical strain, and ensuring ease of use for occupants of all ages and abilities. Ergonomic principles in elevator design not only enhance accessibility but also contribute to a building’s overall safety and usability by reducing physical barriers. As highlighted by Siikonen [

11], well-designed elevators optimize spatial flow and reduce waiting times, which enhances the user experience and supports the efficient movement of people within the building. Therefore, careful thinking about elevator design can bring real improvements to people’s lives [

12].

As universally relevant elements, elevators must be carefully integrated into building designs, with effective wayfinding playing a crucial role in ensuring users can easily locate them [

13]. Clear signage and intuitive layout contribute significantly to the ease of finding elevators, reducing confusion and frustration for occupants [

14]. Research has shown that strategically placed directional signage, combined with visual and tactile cues, can greatly enhance wayfinding in complex environments [

15]. For instance, color-coded pathways leading to elevators can guide users, while well-placed maps at key decision points allow for quick orientation. Moreover, the visibility of elevators from common areas can further improve their accessibility. The ease of finding elevators is particularly important in high-occupancy buildings, where foot traffic is substantial, and delays in accessing vertical transportation can negatively impact the overall user experience [

16].

In addition, using lighting as a wayfinding tool for locating elevators in buildings is an effective design strategy that enhances user experience and accessibility [

17]. Thoughtfully designed lighting can create a welcoming atmosphere and guide occupants intuitively toward elevator lobbies. Furthermore, effective lighting design contributes to the overall ambiance and comfort of waiting areas, allowing occupants to navigate easily and safely.

Moving the focus inside the cabin, internal elements—such as the human–machine interface (HMI)—are crucial for a positive user experience. HMI systems in use today are the result of a trend that has progressed during the 160 years of the evolution of elevators. During the first decades after their transformation into an industrial product and application in civil buildings, elevators were controlled by very complex systems of levers that required the presence of specialized human operators. Automatic buttons first appeared in the 1920s, making elevators more affordable and easier to use. This innovation transformed elevators into mass-produced products, facilitating their widespread adoption in ordinary office and residential buildings [

18].

Despite the elevator industry proposing highly automated elevators, digitally connected controls, and touchless commands to promote seamless movement inside buildings, such products are tailored for high-end applications due to their high costs [

19]. On the contrary, elevators will continue to rely on basic controls in the great majority of buildings for the foreseeable future. Also, existing elevators will likely experience renovations and upgrades, but the fundamental principles of their functioning will not be upgraded as long as they are not decommissioned and changed with completely new installations. Key components of conventional HMI include the control panel, which must feature accessible buttons and clearly labeled warnings and instructions [

20].

Inside the cabin, a key element is the control panel containing all the buttons to operate the elevator. The main functions of the panel include a series of buttons representing the floors being served by the elevator and an alarm button. Some elevators may feature two buttons that override the normal operation of the automatic doors: the most frequent one is the one that shortens the delay in the closing of the doors to improve the velocity of the elevator service, while another one is used to stop and delay their automatic closure, for instance, for people inside the cabin to kindly facilitate the entrance of an arriving passenger.

Innovations like touchless controls are also gaining traction, as they reduce surface contact and potential germ transmission. Also, such modern-looking technologies are sought to transmit an idea of modernity and technology to the users [

21].

However, it is important to note that while touchless buttons can offer benefits and transmit a positive image, they may represent a barrier for several categories of users such as the elderly or blind users [

22]. Blind users may encounter challenges in understanding the system’s current state, as they are unable to rely on visual indicators for feedback. A study [

23] highlights that while tactile feedback can assist in navigation, some visually impaired individuals may find that tactile buttons, which rely heavily on texture and pressure sensitivity, can lead to confusion, particularly in crowded environments where multiple buttons are present. Instead, clearer auditory signals and well-structured interfaces may enhance the overall experience for users with visual impairments. However, these improvements may not address the needs of deaf or hard-of-hearing individuals. Efforts aimed at benefiting one category of users can sometimes create obstacles for another, highlighting a lack of awareness in the elevator design process regarding the needs of people with impairments.

1.2. Regulatory Framework

HMIs, like all other components of elevators, are standardized by many international standards.

Within the European framework, the main reference standard for elevators is Directive 2014/33/EU [

24], which regulates the safety and performance of elevators and their safety components and mentions the need for elevators to be equipped with a two-way communication system. In Europe, elevator components comply with the EN 81 family of technical standards. These standards provide a detailed framework for the features and characteristics of elevator components and are widely recognized as an industry reference, with adoption extending beyond the EU’s geographic boundaries in many cases. Furthermore, the standards of EN 81 series ensure compliance with the European Directive. The most relevant of these regarding button panels and accessibility are as follows:

EN 81-20 [

25] sets the general safety requirements for the design, manufacture, and installation of passenger and goods-passenger lifts;

EN 81-21 [

26] applies when installing new lifts in existing buildings, where space constraints may prevent full compliance with EN 81-20;

EN 81-28 [

27] specifies emergency communication requirements for lifts to ensure trapped passengers can call for assistance;

EN 81-41 [

28] applies to vertical lifting platforms designed for persons with reduced mobility, including wheelchair users;

EN 81-70 [

29] defines accessibility requirements for lifts, ensuring they are usable by people with mobility, visual, and hearing impairments.

These standards outline requirements for the design and installation of lifts, focusing on accessibility for all users, including those with disabilities. The standard framework extensively addresses impaired mobility and, to a lesser extent, impaired vision. Specifically, it defines various indicators for control panels, ensuring that buttons are identifiable visually and by touch. The control panel must include features such as tactile elements, contrasting colors, and audible signals to assist users in navigating the elevator system. The design of the control panel must comply with accessibility standards: both the control panels—the cabin control panel and the floor push button panel—must be positioned at a height such that the maximum distance of the buttons is between 900 and 1100 mm from the floor. Additionally, the cabin control panel should be placed on one of the two side walls at a distance of at least 350 mm from the cabin door. Adhering to the above-mentioned standard, the buttons on the control panels must feature raised numbering and inscriptions with Braille translations. Moreover, a recognition plate in Braille characters should be placed alongside each button on the floor panels.

According to the EN 81-28 standard [

27], each elevator car shall have one alarm device (two-way communication system) permanently connected to a rescue service. The device shall ensure voice communication in both directions.

EN 81-28 [

27] establishes that the alarm system may be designed to filter inadvertent alarm activations by requiring the alarm button to be pressed for a minimum duration, which shall not exceed 3 s.

The above-mentioned standards outline the physical characteristics of the HMI inside an elevator cabin, their position, size, physical appearance, and the operation of the alarm button.

1.3. Aim and Structure of the Research

The present research aimed to test the facility of use of the buttons that are present inside an elevator and the ability of different types of users to operate the cabin during its normal use and in the case of an emergency. A well-designed HMI promotes user comfort and interaction, employing features such as feedback-responsive buttons and auditory confirmation signals [

30]. These aspects can provide reassurance to users, making the elevator experience smoother and more intuitive.

None of the examined standards addresses the needs of individuals with hearing impairments. The EN 81-70 standard contains indications that are voluntarily adopted. This leaves room for significant deviations, such as in the case of touchless controls. On the contrary, as it may lead to potentially serious consequences, the EN 81-28 standard is more rigorously adopted, and the presence of an alarm system is mandatory in all new lifts. According to the EN 81-28 standard, the alarm system consists of vocal communication (through the telephone dialer) that starts after a long press of the alarm button. Operations of visible and audible signals integrate the alarm system. They consist of (1) yellow and audible signals when the communication is established after the filtering, (2) yellow and green signals when the voice communication starts, and (3) just a yellow signal when the voice communication ends.

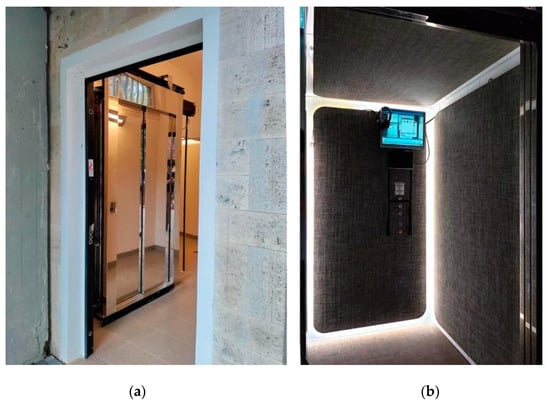

Since EN 81-70 control panels represent the industry standard for most elevators, this research aimed to verify the suitability of a control panel—proposed in two different layouts—that complies with this norm. It also evaluated users’ abilities to operate the elevator correctly and comfortably during both normal and emergency situations.

The paper is organized into three main sections. The first section is organized into several subsections. Firstly, it contains an introduction to the topic, offers a review of the (scarce) scientific literature available, and leads the conversation to the following sections. Secondly, it explores the existing standards framework affecting the HMI in elevators, with a focus on those governing elevator accessibility. European Norms (EN) are used as a reference due to their detailed and comprehensive approach, and they have been adopted in various markets beyond Europe. It then explains the aim and the structure of the research. Lastly, it provides samples and materials used for the research. The second section delves into the methodology employed to evaluate the level of usability of elevator interfaces for generic individuals. This part of the study details the procedural steps undertaken during the research, including the experimental design and data collection methods. The third section discusses the results of the tests and looks at the problem from the particular angle of deaf and hard-of-hearing users describing how such disability may affect the use of elevators. The implications of these findings are discussed in relation to the study aims, and suggestions for future research are provided to further advance the understanding of elevator usability and accessibility for individuals with hearing impairments. The fourth section takes into account the limitations of the study.