1. Introduction

Modern post-endodontic materials, such as milled zirconia, provide esthetic benefits. However, compared to other state-of-the-art materials like selective laser-melted cobalt–chromium and glass fiber posts, milled zirconia displays unique properties and distinct fracture behaviors. Understanding these differences aids in making informed decisions when selecting posts for root-treated teeth.

The hypothesis of this study is that there are no significant differences in the mechanical properties of the tested materials. The aim is to determine whether all materials demonstrate comparable characteristics suitable for the restoration of root canal-treated anterior teeth.

2. Materials and Methods

To compare the primary outcome measure with a power of 80% and a significance level of α = 5%, a sample size calculation determined that seven samples per group were needed to detect a difference of 10 percentage points between the groups, assuming a standard deviation of 6%. A 10% change in mechanical properties is considered a clinically meaningful difference. For this reason, ten samples per group were used to investigate the mechanical properties. Three different materials of post-endodontic posts were studied. Initially, ten quartz fiber-reinforced composite posts of ISO size four in green (X-Post, Dentsply Sirona), consisting of 60% quartz fibers and 40% epoxy resin, were reconstructed in the CAD software “Fusion 360 v.2.0.19994” (Autodesk, San Francisco, California, United States). The designs had identical post geometries and were reproduced using computer-aided manufacturing (CAM).

Ten zirconium oxide posts were milled from a zirconium oxide blank (Copran, Whitepeaks Dental Solutions, Hamminkeln, Germany) using a five-axis milling machine (CORiTEC 150i PRO, imes-icore). The milling process included a lateral support structure, which was later removed and polished.

The metal posts were additively manufactured from a biocompatible cobalt–chromium–tungsten powder (Remanium star CL; Dentaurum) under a nitrogen atmosphere, using a high-power fiber laser (Mlab cusing R; Concept Laser) with a laser power of 56 watts and a scanning speed of 500 mm/s. The layer thickness was set at 30 µm. After fabrication, the posts were sandblasted to achieve a homogenous surface.

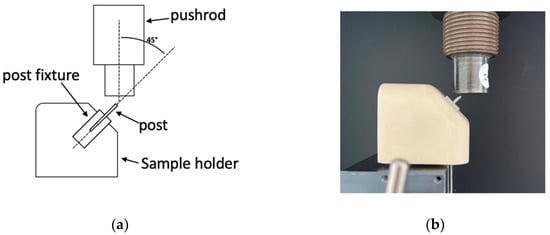

The sample holder, along with the samples, was aligned and fixed in the screw clamp of the testing machine and pre-set to ensure consistent testing conditions. This setup ensured that an angle of 45° between the post axis and the test body was reproducible for each test. A pushrod of 20 mm in diameter was subjected to a displacement rate of 2 mm/min until the fracture of the sample or maximum displacement of 2.5 mm first occurred. The force and displacement were recorded at 100 Hz. The statistical analysis compared the three materials’ stiffness, elasticity limit, and maximum force. A preload of 10 N was applied to ensure the specimen was fully settled in the fixture. This prevented any initial shifting or compliance effects, so that all recorded values accurately represent the material’s response.

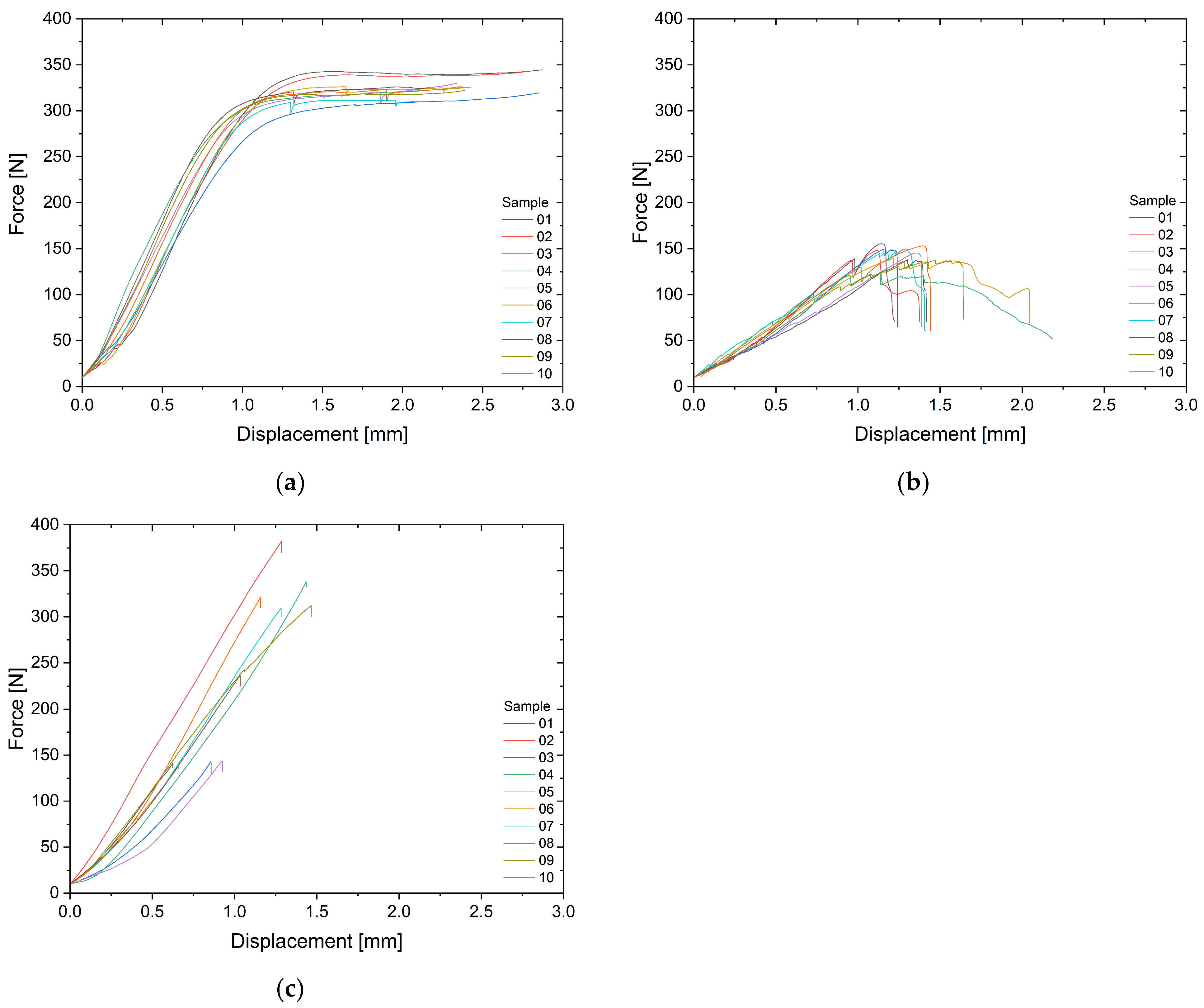

The stiffness, elastic limit, and maximum force were derived from the force–displacement data obtained from mechanical testing. Stiffness was calculated as the ratio of the applied force to the corresponding displacement within the linear (elastic) region of the force–displacement curve. Specifically, the force at the elastic limit was divided by the maximum elastic displacement in mm at that point. This approach provided a measure of stiffness in N/mm, capturing the material’s resistance to elastic deformation. The elastic limit was identified as the point on the force–displacement curve where significant deviation from linearity first occurred, indicating the transition from elastic to plastic behavior. This method allowed us to objectively define the onset of plastic deformation without requiring an offset strain, focusing instead on the visual inflection point where elastic behavior ceased. To assess the load-bearing capacity of each material, the maximum applied force before failure was recorded. Due to the distinct failure behaviors—such as brittle for zirconium oxide, ductile in metal posts, and partial structural breakdown in quartz fibers—this maximum force was selected as a consistent indicator of material performance across varied material types.

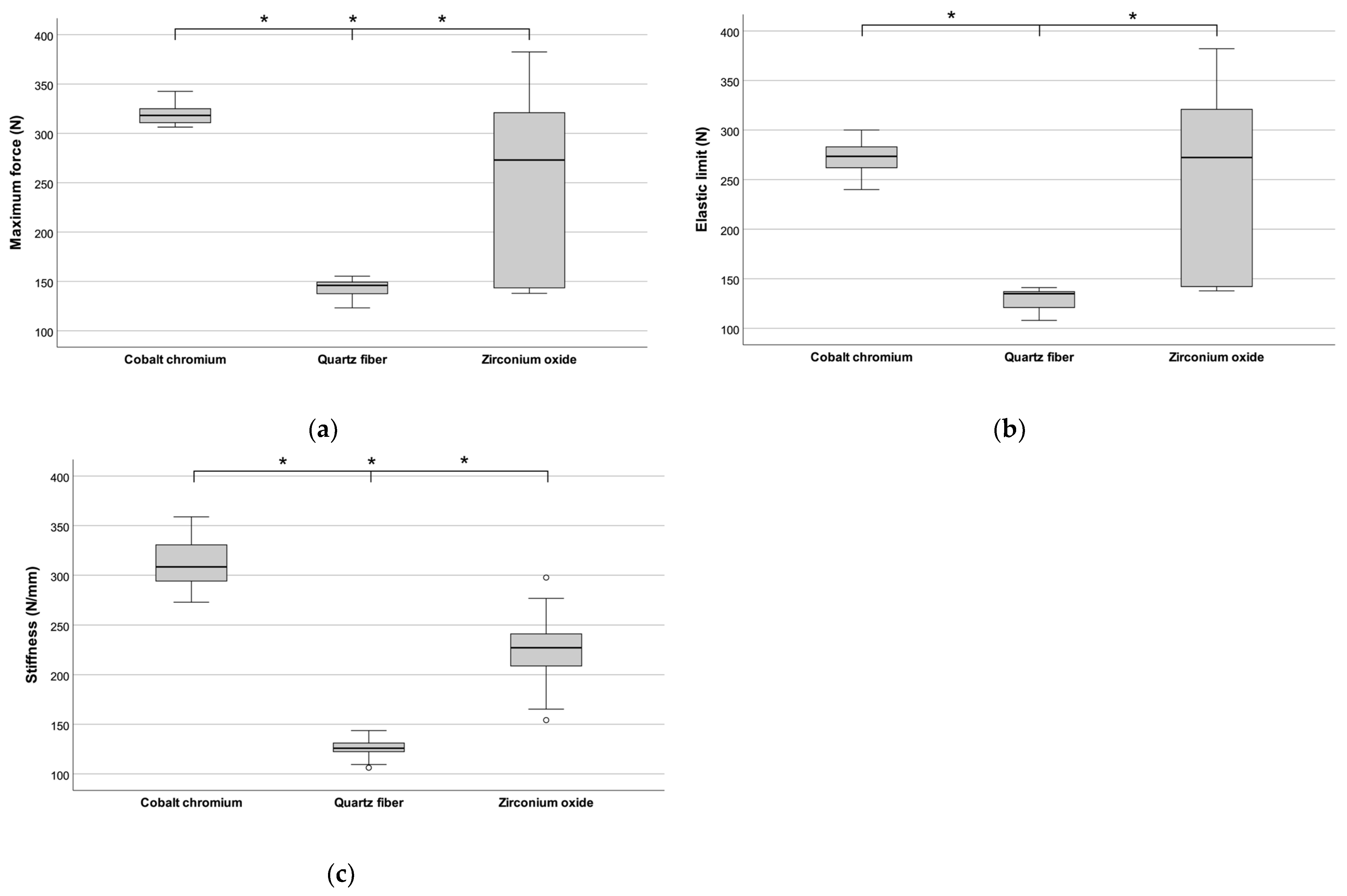

The mean and standard deviation for each parameter were calculated and rounded to two decimal places for clarity. An ANOVA test was conducted to compare the three materials, with the significance level set at p < 0.05. A Tukey post hoc test was employed to find statistical differences between the materials. All calculations were performed using SPSS Statistics Version 27 (IBM, New York, NY, USA).

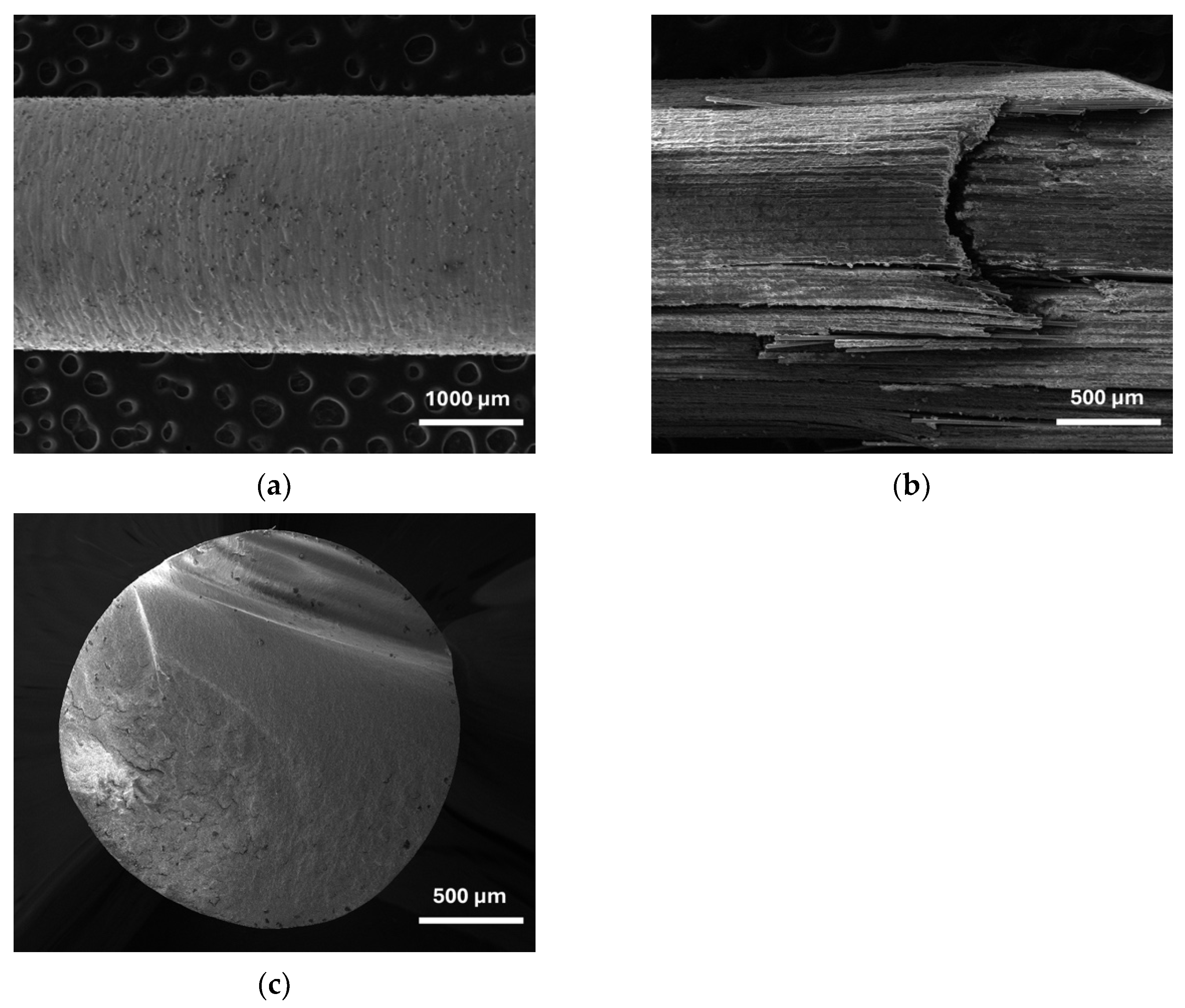

The fracture surface and material surfaces of the specimens were observed using a Field-Emission Gun scanning electron microscope (FEG-SEM), Tescan Mira 3 (Tescan, Brno, Czech Republic). Images were acquired at an acceleration voltage of 10 kV using a secondary electron detector. Non-conductive samples were coated with carbon (~10 nm thickness).

3. Results

Cobalt–chromium posts fell in between, with a stiffness range of 272.7 N to 358.9 N/mm. The elasticity limit of cobalt–chromium posts varied from 240 N to 300 N. Quartz fiber posts had a mean elastic limit of 129.8 N.

The cobalt–chromium posts exhibited the highest maximum force values, with low variation, ranging from 310.7 N to 342.3 N, with a mean value of 323.2 N. In contrast, the zirconium oxide posts showed the largest range, with maximum force values from 137.8 N to 382.1 N and a mean value of 246.1 N.

4. Discussion

The hypothesis of our study, positing no significant differences in the mechanical parameters of the tested materials, can be refuted. The statistical analysis clearly indicated significant variances among the materials, emphasizing the importance of material selection in post-endodontic treatments. Clinical relevance is paramount, especially considering the high occlusal loads that post-endodontic teeth must endure. The focus on compressive-deflection tests under a 45° angled load is particularly relevant, as this angle closely mimics the human interincisal angle and reflects the non-axial nature of masticatory forces in the anterior region. Zirconium oxide posts exhibited a high maximum force (246.1 ± 97.2 N) and stiffness; however, their brittleness was evident due to their limited plastic deformation. The large variance in tensile strength within the zirconium oxide posts group could likely be attributed to the manufacturing process. Manual interventions, such as the removal of lateral support structures during fabrication, may introduce micro-weaknesses, influencing the broad span of force.

In clinical practice, cost is an important factor influencing material selection. While the initial investment for a cobalt–chromium laser melting device is high, the ongoing costs for cobalt–chromium powder and maintenance are relatively low. This cost structure enables amortization with higher production volumes, making cobalt–chromium posts cost-effective in high-demand settings. On the other hand, quartz fiber posts are industrially manufactured and comprise multiple components, which results in moderately higher costs due to the pricing set by manufacturing companies. Thus, these posts lack the customization potential of cobalt–chromium and zirconium oxide posts, manufactured in dental laboratories. Zirconium oxide posts can be produced using milling machines, with lower initial costs than laser melting devices. Zirconium oxide blanks exhibit high fracture resistance, while the operating costs remain low due to minimal tool wear, as the zirconia reaches its final hardness only after the sintering process.

These comparative studies, in conjunction with our findings, highlight the complex interplay of factors influencing the choice of post materials in endodontic treatments. While materials like zirconium oxide and cobalt–chromium show high tensile strength, their behavior under load and mode of failure differ significantly from materials like quartz fiber posts, which exhibit lower tensile strength but different failure characteristics. These differences are crucial for clinicians to consider, as the choice of post material can significantly impact the long-term success and functionality of endodontically treated teeth. The variation in study methodologies, angles of load application, and types of failure also demonstrate the need for a standardized approach in evaluating post materials to draw more universally applicable conclusions.

While this study offers valuable insights, a few minor limitations should be noted. The use of a non-standardized testing setup, including loading at a 45° angle rather than in a traditional bending configuration, was chosen to prioritize clinical relevance, though it limits direct comparability to standardized values. Additionally, the manual preparation of samples, particularly for zirconia, may have introduced variability due to potential effects of post-processing on material integrity. A preload of 10 N was necessary to stabilize the fixture, though it may slightly affect measurement precision at the lower end of the force range.

5. Conclusions

Based on the insights gained from this in vitro study, it can be concluded that the tested post materials can withstand the physiological forces encountered in the anterior region of the mouth. Metal posts, long regarded as the standard reference, exhibit clinically desirable mechanical properties but fall short in meeting esthetic requirements. Quartz fiber-reinforced composite posts present a transparent, simple, and cost-effective alternative. The low elastic modulus of the quartz fiber-reinforced composite helps to reduce stress peaks and the incidence of root fractures. However, they are more prone to loosening and damage due to fiber rupture and matrix cracking, as observed in the SEM images.

Modern esthetic post materials like zirconium oxide exhibit excellent mechanical properties. It is concluded that manufacturing identical posts from metals through additive manufacturing or from zirconium oxide through subtractive manufacturing is technically feasible. Moreover, these posts meet the clinical requirements in terms of mechanical properties. However, it is important to note that the workflow for the subtractive manufacturing of longer posts is not yet fully optimized and has room for improvement.

The findings of this study suggest that zirconium oxide could play a significant role in the future, potentially replacing metal-based custom-made posts in clinical practice. Its outstanding mechanical properties and biocompatible nature, as well as its white color, make it a promising candidate for use in dental restorations, especially in anterior regions. Future research should therefore focus more intensively on this material to fully explore its potential and limitations and develop optimal processing and application strategies.

To advance our understanding of post-and-core systems’ performance in clinical scenarios, randomized clinical trials incorporating various types of posts—both off-the-shelf and custom-made—are warranted. Such studies could offer valuable insights into the long-term success and durability of different post materials in real-world clinical settings.

Author Contributions

Methodology, A.S. (Armin Sokolowski), F.G.W., B.R. and A.S. (Alwin Sokolowski); Software, B.R.; Validation, F.G.W., B.R. and M.R.; Formal analysis, A.S. (Armin Sokolowski), L.S. and L.K.-B.; Investigation, A.S. (Armin Sokolowski), F.G.W., L.S., L.K.-B. and A.S. (Alwin Sokolowski); Resources, M.R.; Data curation, L.S. and M.R.; Writing—original draft, A.S. (Armin Sokolowski) and L.S.; Writing—review & editing, A.S. (Armin Sokolowski), F.G.W. and A.S. (Alwin Sokolowski); Visualization, F.G.W. and M.R.; Supervision, A.S. (Armin Sokolowski), L.K.-B. and A.S. (Alwin Sokolowski); Project administration, A.S. (Alwin Sokolowski). All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data supporting the findings of this study are available from the corresponding author upon reasonable request.

Acknowledgments

The authors thank Irene Mischak (Department of Dental Medicine and Oral Health, Medical University of Graz, Austria) for her statistical consultation. The authors also thank the laboratory technician Philipp Tepesch (Department of Dental Medicine and Oral Health, Medical University of Graz, Austria) for his exceptional contributions in producing the cobalt–chromium posts, the dental laboratory BananaCAD for the production of the zirconium posts, and Martin Lorenzoni (Former Chair of Division of Restorative Dentistry, Periodontology and Prosthodontics, Medical University of Graz, Austria) for generously providing the necessary infrastructure to support our investigation.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Iaculli, F.; Rengo, C.; Lodato, V.; Patini, R.; Spagnuolo, G.; Rengo, S. Fracture Resistance of Endodontically-Treated Maxillary Premolars Restored with Different Type of Posts and Direct Composite Reconstructions: A Systematic Review and Meta-Analysis of in Vitro Studies. Dent. Mater. 2021, 37, e455–e484. [Google Scholar] [CrossRef] [PubMed]

- Alhajj, M.N.; Qi, C.H.; Sayed, M.E.; Johari, Y.; Ariffin, Z. Fracture Resistance of Titanium and Fiber Dental Posts: A Systematic Review and Meta-Analysis. J. Prosthodont. 2022, 31, 374–384. [Google Scholar] [CrossRef] [PubMed]

- Bacchi, A.; Fernandes dos Santos, M.; Pimentel, M.; Caetano, C.; Sinhoreti, M.A.; Consani, R.L. Influence of Post-Thickness and Material on the Fracture Strength of Teeth with Reduced Coronal Structure. J. Conserv. Dent. 2013, 16, 139. [Google Scholar] [CrossRef] [PubMed]

- Veeraganta, S.K.; Samran, A.; Wille, S.; Kern, M. Influence of Post Material, Post Diameter, and Substance Loss on the Fracture Resistance of Endodontically Treated Teeth: A Laboratory Study. J. Prosthet. Dent. 2020, 124, e1–e739. [Google Scholar] [CrossRef] [PubMed]

- Samran, A.; El Bahra, S.; Kern, M. The Influence of Substance Loss and Ferrule Height on the Fracture Resistance of Endodontically Treated Premolars. An in Vitro Study. Dent. Mater. 2013, 29, 1280–1286. [Google Scholar] [CrossRef] [PubMed]

- Dejak, B.; Młotkowski, A. The Influence of Ferrule Effect and Length of Cast and FRC Posts on the Stresses in Anterior Teeth. Dent. Mater. 2013, 29, e227–e237. [Google Scholar] [CrossRef] [PubMed]

- Balkenhol, M.; Wöstmann, B.; Rein, C.; Ferger, P. Survival Time of Cast Post and Cores: A 10-Year Retrospective Study. J. Dent. 2007, 35, 50–58. [Google Scholar] [CrossRef] [PubMed]

- Evans, E.J.; Thomas, I.T. The in Vitro Toxicity of Cobalt-Chrome-Molybdenum Alloy and Its Constituent Metals. Biomaterials 1986, 7, 25–29. [Google Scholar] [CrossRef] [PubMed]

- Al Jabbari, Y.S. Physico-Mechanical Properties and Prosthodontic Applications of Co-Cr Dental Alloys: A Review of the Literature. J. Adv. Prosthodont. 2014, 6, 138. [Google Scholar] [CrossRef] [PubMed]

- van Noort, R. The Future of Dental Devices Is Digital. Dent. Mater. 2012, 28, 3–12. [Google Scholar] [CrossRef] [PubMed]

- Naumann, M.; Koelpin, M.; Beuer, F.; Meyer-Lueckel, H. 10-Year Survival Evaluation for Glass-Fiber-Supported Postendodontic Restoration: A Prospective Observational Clinical Study. J. Endod. 2012, 38, 432–435. [Google Scholar] [CrossRef] [PubMed]

- Bateli, M.; Kern, M.; Wolkewitz, M.; Strub, J.R.; Att, W. A Retrospective Evaluation of Teeth Restored with Zirconia Ceramic Posts: 10-Year Results. Clin. Oral. Investig. 2014, 18, 1181–1187. [Google Scholar] [CrossRef] [PubMed]

- Kalyoncuoğlu, E.; Ural, Ç.; Aydemir, H.; Aslan, M.A.; Balkaya, V. Effect of 1-Piece Post and Core Fabrication Techniques on Fracture Strength. J. Appl. Biomater. Funct. Mater. 2015, 13, 253–258. [Google Scholar] [CrossRef] [PubMed]

- Martins, M.D.; Junqueira, R.B.; de Carvalho, R.F.; Lacerda, M.F.L.S.; Faé, D.S.; Lemos, C.A.A. Is a Fiber Post Better than a Metal Post for the Restoration of Endodontically Treated Teeth? A Systematic Review and Meta-Analysis. J. Dent. 2021, 112, 103750. [Google Scholar] [CrossRef] [PubMed]

- Sarkis-Onofre, R.; Amaral Pinheiro, H.; Poletto-Neto, V.; Bergoli, C.D.; Cenci, M.S.; Pereira-Cenci, T. Randomized Controlled Trial Comparing Glass Fiber Posts and Cast Metal Posts. J. Dent. 2020, 96, 103334. [Google Scholar] [CrossRef] [PubMed]

- Lambjerg-Hansen, H.; Asmussen, E. Mechanical Properties of Endodontic Posts. J. Oral. Rehabil. 1997, 24, 882–887. [Google Scholar] [CrossRef] [PubMed]

- Asmussen, E.; Peutzfeldt, A.; Heitmann, T. Stiffness, Elastic Limit, and Strength of Newer Types of Endodontic Posts. J. Dent. 1999, 27, 275–278. [Google Scholar] [CrossRef] [PubMed]

- Lo Giudice, G.; Cagidiaco, E.F.; Lo Giudice, R.; Puleio, F.; Nicita, F.; Calapaj, M. Evaluation of Mechanical Properties of a Hollow Endodontic Post by Three Point Test and SEM Analysis: A Pilot Study. Materials 2019, 12, 1983. [Google Scholar] [CrossRef] [PubMed]

Testing machine with custom-made fixture clamping samples at 45° angle—schematic diagram (a), experimental setup (b).

Figure 1.

Testing machine with custom-made fixture clamping samples at 45° angle—schematic diagram (a), experimental setup (b).

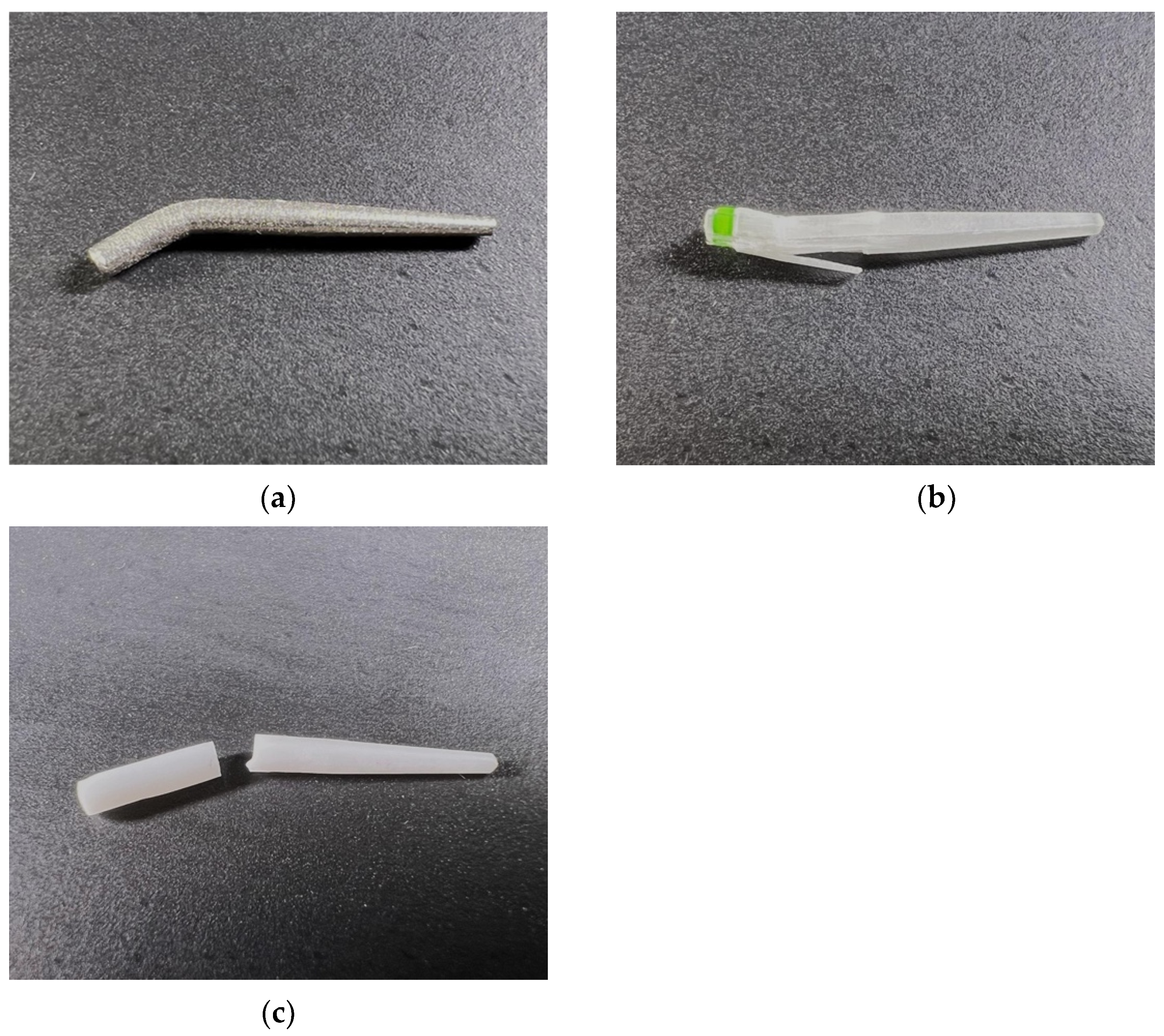

Samples (posts) after test at 45°: (a) cobalt–chromium alloy, (b) quartz fiber-reinforced composite, (c) zirconium oxide.

Figure 2.

Samples (posts) after test at 45°: (a) cobalt–chromium alloy, (b) quartz fiber-reinforced composite, (c) zirconium oxide.

Force–displacement curves depicting group characteristics. (a) 10 cobalt–chromium posts, (b) 10 quartz fiber posts, (c) 10 zirconium oxide posts.

Figure 3.

Force–displacement curves depicting group characteristics. (a) 10 cobalt–chromium posts, (b) 10 quartz fiber posts, (c) 10 zirconium oxide posts.

Box plots of tensile testing results. (a) Maximum force, (b) elastic limit, (c) stiffness. Statistically significant results marked with asterisk (*) (n = 10, p < 0.001).

Figure 4.

Box plots of tensile testing results. (a) Maximum force, (b) elastic limit, (c) stiffness. Statistically significant results marked with asterisk (*) (n = 10, p < 0.001).

SEM images at the posts’ maximum displacement point: (a) Surface of cobalt–chromium alloy. (b) Detail of the fracture zone of the quartz fiber post. (c) Detail of the fracture surface of the zirconium oxide post.

Figure 5.

SEM images at the posts’ maximum displacement point: (a) Surface of cobalt–chromium alloy. (b) Detail of the fracture zone of the quartz fiber post. (c) Detail of the fracture surface of the zirconium oxide post.

Table 1.

The stiffness, elastic limit, and maximum force of the studied materials.

Table 1.

The stiffness, elastic limit, and maximum force of the studied materials.

| Parameter | Material | Min | Max | Mean | SD |

|---|---|---|---|---|---|

| Maximum force (N) | Cobalt–chromium | 310.7 | 342.3 | 323.2 | 10.5 |

| Quartz fiber | 122.3 | 156.2 | 143.3 | 9.9 | |

| Zirconium oxide | 137.8 | 382.1 | 246.1 | 97.2 | |

| Elastic Limit (N) | Cobalt–chromium | 240.0 | 300.0 | 273.3 | 16.9 |

| Quartz fiber | 108.0 | 141.0 | 129.8 | 11.0 | |

| Zirconium oxide | 137.8 | 382.1 | 246.1 | 97.2 | |

| Stiffness (N/mm) | Cobalt–chromium | 272.7 | 358.9 | 313.2 | 28.5 |

| Quartz fiber | 106.2 | 143.6 | 126.1 | 12.2 | |

| Zirconium oxide | 154.2 | 297.6 | 224.5 | 43.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

Source link

Armin Sokolowski www.mdpi.com