4.1. Shokry’s MJC-1 (S1-MJC)

The MJC model developed by Shokry [70] is modified in this study to improve its accuracy in predicting the deformation behavior of AA6082 at several values of and by incorporating a linear relationship that directly links with and . The S1-MJC model is formulated below:

For obtaining the S1-MJC model’s constants, and are set as 400 °C and 0.001 s−1. Therefore, Equation (29) simplifies to the following:

Through regression analysis, was determined to be 58.071 MPa, was −11.065 MPa, was −22.881 MPa, and was 27.824 MPa.

After modifications and at = 400 °C, Equation (29) is described below:

Using regression, was determined to be 0.0616 and was 0.0641. After applying the natural logarithm and simplifying, Equation (29) can be expressed in various values as follows:

Using regression, was determined to be 1.4884 and was determined to be −0.3467. The S1-MJC model constants of the AA6082 alloy are written in Table 5.

Therefore, the S1-MJC model of AA6082 alloy is presented below:

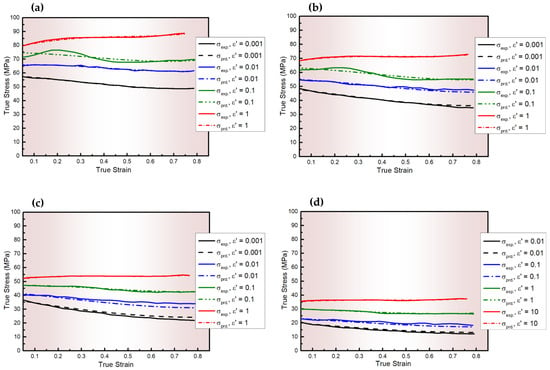

Figure 3 compares the experimental flow stresses of AA6082 and those determined via the S1-MJC model, with R = 0.983, AARE = 7.09%, and RMSE = 3.56 MPa, as listed in Table 6. As depicted, the results predicted by the S1-MJC model align closely with the experimental data, demonstrating a better fit than the MZA model; however, the S1-MJC model still does not outperform the accuracy achieved with CP modeling. This improved accuracy is because the S1-MJC model integrated both and the softening effects and strain hardening in the model. It is well-established that dislocations are influenced by and softening.

4.2. Shokry’s MJC-2 (S2-MJC)

The MJC model developed by Shokry et al. [71] is implemented in this study for determining the hot-flow behavior of AA6082 Al-Mg-Si over a wide range of and . Their model is represented below:

In this investigation, to determine the S2-MJC model’s constants, was adjusted to 0.001 s−1, and was adjusted to 400 °C. Consequently, Equation (34) is simplified to the following:

Expanding Equation (35) results in four parts including , each associated with four constants. Through regression, these constants were 58.071 MPa, −11.065 MPa, −22.881 MPa, and 27.824 MPa. Thus, at 400 °C, and after performing some adjustments, Equation (34) is presented below:

Expanding Equation (36) results in nine parts, including and , each linked to a corresponding constant. Through regression, these constants were 0.0550, 0.0828, −0.0888, 0.1637, −1.2841, 1.2652, −0.1126, 1.0707, and −1.0288. After applying the natural logarithm and making adjustments, Equation (34) can be expressed in various values as follows:

Expanding the right side of Equation (37) results in 27 parts, including , and . Through regression, these constants were obtained to be −0.6668, 2.7593, −2.4307, −0.2755, −5.5232, 5.0762, −0.1888, 2.1973, −1.5661, −0.0198, −10.3673, 9.3805, −2.597, 56.627, −53.125, 2.2348, −35.0907, 32.2649, −1.6642, 16.4578, −14.7332, 3.5334, −73.087, 68.9637, −2.7157, 52.349, and −49.0335, as listed in Table 7.

To determine the constants for the SI-MJC and S2-MJC models, the corresponding equations are rearranged to isolate the constants on the right-hand side. Although the relationships between the predictors , , and and the response (the equation’s output on the left-hand side) are nonlinear, the equations are linear with respect to the constants (coefficients). Therefore, a linear regression model using the least-squares method is employed to compute the constants for the three models in MATLAB.

Figure 4 shows comparisons between the experimental stresses of AA6082 and those determined via the S2-MJC model, with R = 0.99, AARE = 1.87%, and RMSE = 0.95 MPa. As depicted in Figure 4 and Table 8, the result predicted by the S2-MJC model closely aligns with the experimentation, showing a better fit than the previous models and close to the accuracy achieved with CP modeling. This improved accuracy is because the S2-MJC model integrated both and on the one hand, and , and on the other hand, facilitated by an extensive set of constants that link the softening and dynamic recovery components.

The R values for the developed models are presented in Figure 5a. The CP and S2-MJC models achieve the highest R values close to 1, with values of 0.999 and 0.99, respectively. In contrast, R for the MZA is 0.951 and for S1-MJC is 0.983. Similarly, Figure 5b,c display these models’ AARE and RMSE values. The CP and S2-MJC models exhibit the best performance with the lowest values of AARE, which are 1.1% and 1.87%, respectively. The values of RMSE are 0.55 MPa and 0.95 MPa, respectively. Moreover, the MZA and S1-MJC models yield higher AARE values of 11.67% and 7.09% and RMSE values of 7.23 MPa and 3.56 MPa, respectively. The obtained values of R, AARE, and RMSE indicate that the MZA and S1-MJC models can be used to predict the flow behavior of the studied alloy but with limited accuracy. The MZA model accounts for the coupling effects between and as well as between and . In contrast, the S1-MJC model considers the coupling effects between and as well as between and . Moreover, the CP and S2-MJC models incorporate the coupling effects between , and . Given the nonlinear nature of the flow behavior of the studied alloy, models that account for the more comprehensive coupling between , and are expected to provide more accurate predictions.

Source link

Bandar Alzahrani www.mdpi.com