This structured methodology provides a systematic approach to assessing the role of coopetition practices in enhancing BIM effectiveness within the Portuguese ornamental stone sector. By clearly outlining the research procedure, this framework allows for replicability and offers a foundation for future studies to expand on these findings in other sectors.

4.1. Selecting Participants

The sector’s mix of tradition and modernity and its readiness to engage in digital transformation make it an exemplary case for testing the hypothesis. The selection of participants for the Experimental Coopetition Network is based on criteria such as technological capability, openness to collaboration, and strategic importance within the industry. This approach ensures that the study captures a representative sample of the sector, providing valuable insights into the broader applicability of coopetition practices in enhancing BIM benefits.

Recognizing these characteristics in the Portuguese ornamental stone sector, the first step involved establishing direct and informal communication channels with the managing directors of potential participant companies, a process that uncovered three significant operational challenges:

Technological Capability: The first challenge was the limited number of companies with production systems capable of real-time connectivity to meet BIM procurement requirements. Given that BIM demands high levels of precision and interoperability, only a subset of 43 companies out of the 661 in the sector were found to have the necessary digital infrastructure. After in-person evaluations of these 43 companies, 23 were pre-selected based on their ability to integrate with an Industrial IoT platform.

Logistical Complexity and Costs: The second challenge involved the logistical complexities and costs of implementing the Experimental Coopetition Network and operationalizing data collection. The experimental nature of the project, combined with budget constraints, required careful planning to ensure its viability. Given the budget limitations, the number of participating companies had to be reduced to a minimum to manage costs effectively and create a controlled environment for testing the feasibility of BIM integration. The data collection period was also limited to two months to ensure the project remained within budget while providing meaningful insights.

Data Sharing Reluctance: The third and perhaps most critical challenge was the reluctance of companies to share sensitive data, a common issue in industries where proprietary knowledge is a critical competitive asset. In the context of BIM, where the success of a project relies on transparent and accurate data exchange, this reluctance posed a significant barrier. To overcome this, a comprehensive confidentiality agreement was developed to reassure participating companies that their competitive positions would not be compromised by their involvement in the network. This agreement covered all aspects of operations, including clientele, employee information, resources, and competitive strategies.

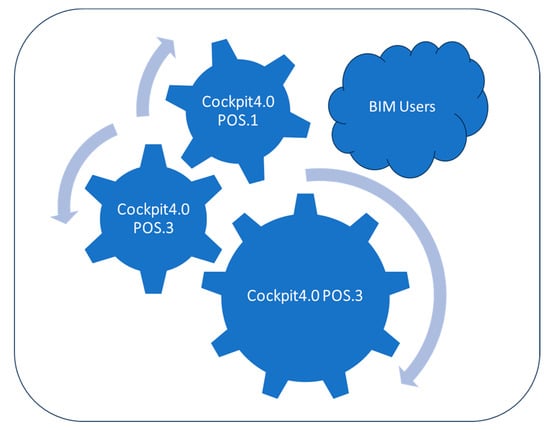

As a result of these strategic considerations, three ornamental stone companies formally committed to participating in the study, with confidentiality agreements signed to protect their interests. To maintain the integrity of the research and safeguard the identities of the companies involved, they are referred to anonymously as “POS.1”, “POS.2”, and “POS.3”.

This Experimental Coopetition Network functioned as a laboratory for collecting data on independent variables to explore the benefits of coopetition practices, treated as dependent variables, in testing the hypothesis that coopetition practices can positively influence manufacturers’ contributions and enhance the benefits of BIM. By fostering a coopetition environment, these selected companies could improve their ability to meet BIM requirements more effectively.

With complete participant selection and confidentiality agreements in place, the study established the Experimental Coopetition Network. This network aimed to leverage advanced Industrial IoT technology, creating a collaborative environment where participating companies could integrate their operations seamlessly. The following section describes the implementation process of this network, focusing on the technological infrastructure, including Cockpit4.0+, and the steps taken to enable secure, real-time data exchange between firms to support BIM applications.

4.2. Implementation of the Experimental Coopetition Network

By embedding OPC-UA protocols, Cockpit4.0+ addresses gaps in connectivity, efficiency, and responsiveness, creating a network where companies can thrive through collective innovation and adaptive strategies. Integrating technological innovations, such as artificial intelligence, further promotes a collaborative industrial environment, ensuring sustainable operations and competitiveness among participating companies.

In each POS company involved in the case study, a Cockpit4.0+ system was installed, ensuring secure connectivity among companies and facilitating potential connections to BIM stations interested in prescribing customized stone globally.

With the Experimental Coopetition Network successfully established, the study defined specific metrics and KPIs necessary for assessing the impact of coopetition practices on BIM integration. The following section outlines the KPIs selected for this purpose, each aligned with the core dimensions of BIM (4D, 5D, and 6D). These metrics provide a structured approach to measuring improvements in time management, cost efficiency, and environmental sustainability—key areas where coopetition practices are expected to enhance BIM’s effectiveness in the construction industry.

4.3. Defining Metrics and KPIs for BIM Integration

BIM’s effectiveness in construction projects heavily depends on how well each component aligns with the requirements of the various BIM dimensions. The BIM.4D dimension integrates the element of time into the digital model, significantly enhancing time synchronization, accountability, and communication throughout the project lifecycle. BIM.4D enables the real-time visualization of construction sequences, which is essential for dynamic and timely project delivery.

Improvements in KPIOtD are therefore critical for enhancing the overall effectiveness of BIM.4D. A higher KPIOtD means that the manufacturer is more reliably delivering components as per the project’s timeline, which supports the accurate and timely execution of the construction plan. This alignment between delivery schedules and project timelines minimizes delays and disruptions, ensuring that the benefits of BIM.4D BIM—such as improved planning, better resource management, and enhanced project coordination—are fully realized.

Enhancing KPILP is directly aligned with the requirements of BIM.5D. A higher KPILP indicates that a manufacturer is producing more with the same or fewer resources, effectively reducing costs without compromising quality. This increased efficiency supports the goals of BIM.5D by lowering overall construction costs while maintaining the project’s financial health.

By improving labor productivity, stone companies can contribute to more efficient cost management throughout the project lifecycle. This alignment between labor productivity and cost efficiency is crucial for maximizing the benefits of BIM.5D, ensuring that projects are completed within budget and provide better value for stakeholders. The focus on optimizing labor inputs while maintaining output quality directly impacts the project’s financial performance, making KPILP a vital metric for evaluating the success of BIM.5D in BIM-enabled construction projects.

Equation (3) can be employed to calculate the CO2 equivalent (KPICO2-eq) for producing parts, reflecting the energy consumed (EC) per part delivered (PD). This metric allows for a precise evaluation of the environmental impact of manufacturing processes, enabling fabricators to assess their alignment with the sustainability objectives of BIM.6D.

By reducing the KPICO2-eq, manufacturers can directly contribute to the environmental goals of BIM.6D, ensuring that their operations are efficient and environmentally responsible. This alignment with BIM.6D requirements is essential for promoting sustainable practices within the construction industry and achieving broader environmental targets, such as those outlined in the Sustainable Development Goals (SDGs).

Reductions in KPICO2-eq directly contribute to lowering the construction industry’s CO2 emissions and support SDG 11—Sustainable Cities and Communities—by promoting environmentally responsible practices and reducing urban carbon footprints.

With the KPIs established, the study progressed to an empirical assessment of the impact of coopetition practices on these metrics. The following section details the comparative analysis conducted over two distinct 54-day intervals, capturing baseline practices versus coopetition practices. This approach allows for an in-depth evaluation of how coopetition influences time efficiency, cost-effectiveness, and environmental impact, thereby providing valuable insights into the effectiveness of BIM dimensions within the Experimental Coopetition Network.

Source link

Agostinho da Silva www.mdpi.com