1. Introduction

The forestry and pulp industry represented 1.35% of Chilean GDP in 2022 (USD 3.355 billion), equivalent to 6.8% of exports [

1]. Globally, Chile accounts for 2.24% of wood products and 7% of total pulp for paper, making it the fourth-largest exporter [

2]. Specifically, the Bio-Bío Region accounts for 60% of forestry GDP, followed by the Araucanía Region with 10.5% [

3]. Chile’s forestry area covers 41.3 million hectares, including forests and grasslands [

4]. Of this, 13% are monoculture plantations, with 55.8% radiata pine and 37.2% Eucalyptus [

5]. Eucalyptus plantations have increased over the years; in the 1990s, there were 8 ha of pine/1 ha of Eucalyptus, but by 2016, this had risen to 1.5 ha of pine/1 ha of Eucalyptus [

3].

In 2015, plantation harvesting reached 43.6 million m

3/year, with 36.5% for chemical pulp production [

6]. The industry focuses on cellulose for products like tissue paper and sanitary napkins [

7]. The sector expanded in the 1970s, reaching an annual cellulose production of 7.8 million tonnes in 2018 [

8,

9]. However, there are socio-environmental conflicts [

10] due to water resource use, pesticides, ecosystem disruption, and soil acidification, among others [

11,

12,

13,

14]. Additionally, conflicts with Indigenous peoples over land ownership persist [

15].

Pulp mills, which require high water consumption and produce toxic effluents, have also been contentious [

16,

17,

18]. The environmental impact of pulp production in Chile remains inadequately assessed. Life cycle environmental assessment has been used to evaluate the potential impacts of obtaining bleached pulp. A study comparing three production techniques (mechanical, chemical, and bio pulping) shows that the latter has several environmental advantages over the production of chemical pulp, although it presents a higher strength [

19]. Chemical Kraft cellulose from short-fibre Eucalyptus globulus in Portugal reports CO

2 emissions of 400 kg of CO

2eq/tonne of cellulose [

20], mainly associated with on-site energy generation and transportation from the forestry site to the pulp mill. A similar result of 431.3 kg CO

2eq/tonne of pulp was reported from the total chlorine-free (TCF) Eucalyptus cellulose process, where only the greenhouse gas (GHG) emissions from fossil fuels were considered [

21]. From this, about 65% of the emissions are associated with burning fuel in the lime kiln, followed by producing chemical supplies with 31%. This work excludes transport from the forestry site to the production plant [

21]. Those impacts are lower than the result from Ecoinvent, where a higher GHG emission is reported (779 kg

CO2eq/tonne of bleached cellulose) for elemental chlorine-free (ECF) Kraft cellulose pulp [

22]. This difference is attributed to the integrity of the database, which includes all the process stages.

For Chilean forestry production, the life cycle GHG emissions of Eucalyptus globulus chips are 16.3 kg CO

2eq /m

3 of chips [

23], mainly from pruning, thinning, machinery, and vehicles [

12]. Including the chemical process, 1.5 tonnes of CO

2fossil and 1.83 tonnes of CO

2biogenic are emitted per tonne of bleached cellulose [

24]. It was the first study conducted in Chile. Then, an update of the same study [

25] reports 120 kg of CO

2fossil/tonne of cellulose, significantly reduced due to technological improvements. This is lower than Spain’s 431.3 kg CO

2eq/tonne [

21], but comparable to another South American plant with 140–310 kg CO

2/tonne [

26] direct fossil emissions. Differences arise from variations in production processes and indirect process coverage. Emissions from Chilean pulp production include 2.9 kg of NO

x/tonne due to the transport from plantations to the pulp plant, followed by the burning of black liquor in the recovery boiler [

21,

27]. The last result for Terrestrial Acidification Potential in Chile [

25] reaches 3.4 kg of SO

2 eq/tonne of bleached cellulose, which is slightly above the value reported in 1998 (2.1 kg of SO

2/tonne [

24]). Pulp bleached with chlorine dioxide results in high concentrations of COD and AOX [

21,

27], and this is sensitive for national case [

24].

On the other hand, since biogenic emissions are considered carbon-neutral [

26,

28,

29], this enhances the sector’s role in mitigating climate change. The biogenic emissions of the pulp sector in Chile have been reported to be between 1600 kg CO

2/tonne and 2400 kg CO

2/tonne of bleached pulp, mainly from biomass burning [

26], displacing fossil sources, and comprising about 90% of the cellulose industry’s CO

2 output [

21]. For this reason, an increase in biogenic emissions is expected.

Recent studies in Finland [

30], China [

31], and Norway [

32] have assessed the pulp and paper process, focusing on plantation management, chemical supply, and energy sources. However, Chile has no comprehensive life cycle assessment covering forestry cultivation, growth, harvest, log transport, and bleached pulp production. This work contributes to the integrated environmental analysis of Chile’s silvicultural-forestry-industrial system, providing valuable management information and allowing comparison and identification of high environmental burdens in both forestry and industrial processes.

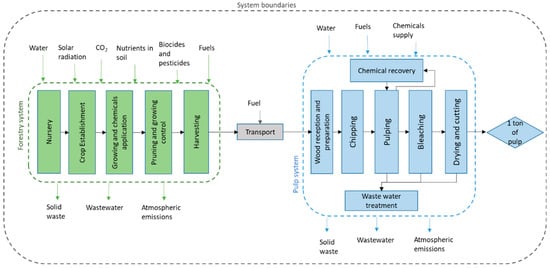

This study presents the methodology, including the goal, scope, data requirements, treatments, and impact method used. Then, the results are discussed to finalise the conclusions.

3. Results and Discussion

The results and their analysis are presented for each process subsystem, ending with a global comparative analysis.

3.1. Life Cycle Impact Assessment

3.1.1. Forestry Subsystem

The impacts were categorised by the type of activity involved: (i) chemical and materials supply, (ii) transport and machinery, and (iii) forest growth (

Figure 2). Transportation has a significant contribution, ranging from 3.9% to 86.6% across all impact categories. This contribution is largely determined by the fuel use intensity in rolling stock and/or harvesting machinery. Specifically, transportation contributes over 66% in the GWP, OF-HH, TET, FWET, MET, and HCT categories, primarily due to the utilisation of the harvester.

Chemical supplies, on the other hand, play a substantial role, accounting for more than 28% in the WC and FWET-MET categories. This contribution is primarily attributed to the use of diammonium phosphate. Conversely, forest growth exhibits a contribution of over 63% in the TA, SOD, and MAEU categories. This high contribution results from the emission of nitrogen and phosphate agents from fertilisation and the application of biocidal agents.

3.1.2. Industrial Subsystem

The resource requirements involved in the pulping process have been categorized into seven groups: (i) chemical supply production, (ii) fuels production, (iii) transport, (iv) pulpwood production, (v) electricity purchased, (vi) waste treatment, and (vii) pulping itself (as depicted in

Figure 3). Among these categories, pulping contributes the largest environmental load, exceeding 43% in three of the ten indicators (OF-HH, TA, and WC). This significant contribution can be attributed to the release of gases and the extensive water consumption involved in the pulping process. Pulpwood, on the other hand, plays a major role in the indicators of SOD and MAEU, accounting for 79% and 86%, respectively. This is primarily due to the presence of nitrogen-based fertilisers and biocides that are swept along the rivers’ flow. The chemical supply contributes 8–26% in nine out of the ten indicators, highlighting its significance in the overall environmental impact. Similarly, electricity consumption is relevant in all categories, particularly in FWET and MET, where it accounts for over 56% of the total load, primarily due to the utilisation of fossil energy sources.

Transport’s primary contribution can be observed in the TET indicator, which accounts for 56% of the environmental impact. On the other hand, waste treatment displays a notable impact in the HCT indicator, with a contribution of 74%.

3.2. Environmental Impact Assessment by Category

The details of the contributions are presented below, individualising the results for each impact category. The detailed data are reported in

Supplementary Information.

- (a)

Global warming potential (GWP): The forest stage emits 32.5 kg CO

2eq/tonne of wood. Transportation and machinery contribute to over 66% of the overall impact. The harvest process alone accounts for approximately 47% of the total impact. Furthermore, around 27.5% of the impact is attributed to fugitive emissions of N

2O, resulting from the use of nitrogen-based fertilisers [

13]. The GWP is 784 kg CO

2eq/tonne of pulp in the pulping stage. The main contributors are electricity consumption (32%), primarily due to its reliance on coal (contributing 38%), chemical supplies (22%), such as sodium chlorate, which contributes 12.6% to the impact, and the pulping process itself (23%).

- (b)

Stratospheric ozone depletion (SOD): the SOD of the forest process reached 3.44 × 10

−4 kg CFC-11

eq/tonne wood, with nitrogen fertilisers accounting for 95% of this value due to their fugitive N

2O emissions [

23]. In the pulping process, the SOD was found to be 0.00113 kg CFC-11

eq/kg, with 79% of this contribution coming from the forestry process. Additionally, the production of chemical supplies accounted for 8% of the SOD, while the treatment of waste resulting from ammonia, nitrogen oxides, and nitrous oxide emissions contributed 5%.

- (c)

Ozone formation-human health (OF-HH): the OF-HH in the forestry process was 0.192 kg NOx eq/tonne wood with the machinery, such as the forwarder and the harvester, contributing more than 67% through the generation of CO, COV, NO, and NO

x. The OF-HH of the pulping process reached 4.41 kg NO

xeq/tonne of pulp, with 43% attributed to NO

x and NH

3 emissions reported to the RETC [

42] while electricity accounts for 26%. The wood transport to the plant and the harvester use contributes 11%.

- (d)

Terrestrial acidification (TA): the TA for the forest stage was 0.257 kg SO

2eq/tonne of wood, aligning with the findings [

23] (0.25 kg SO

2eq/tonne of chip). Fertilisers and biocides contribute to soil acidification, accounting for 63.2% of the impact category. Combustion from the harvester and the forwarder accounts for 30.1% of the TA [

51]. On the other hand, the TA in the pulp reached 9.38 kg SO

2eq/tonne of pulp, with 69% of emissions originating from the direct process. The main contribution comes from the lime kiln [

20,

21,

30] due to the sulfur content of the fuel oil used.

- (e)

Marine aquatic eutrophication (MAEU): the MAEU of the forest stage is 0.127 kg N

eq/tonne of wood, with over 99% of this being attributed to using fertilisers and biocides. Once transformed and transported in the environment, these substances ultimately end up in the sea. Interestingly, this result is 65% lower than the findings of Morales et al. (2015) [

23], which can be attributed to the different considerations and systems analysed in our study. Additionally, the MAEU for cellulose production is 0.384 kg N

eq/tonne, with 86% of this stemming from using fertilisers and biocides in wood production. It is important to note that these substances not only pose a risk of surface and groundwater contamination but also have detrimental effects on ecosystems and human health [

52].

- (f)

Terrestrial ecotoxicity (TET), Freshwater ecotoxicity (FWET), Marine ecotoxicity (MET): in the forestry process, TET reached 76.6 kg 1.4-DCB/tonne of wood, FWET reached 0.31 kg 1.4-DCB/tonne, and MET reached 0.463 kg 1.4-DCB/tonne Machinery. Transport plays a significant role in all three indicators, contributing at least 70% to each impact category (viz.

Figure 3). The harvester, in particular, accounted for 44–58% of the impact, with its manufacturing, operation, and peripheral systems like tyre wear and brake system all contributing [

53]. Among the chemical supplies used in the forestry process, diammonium phosphate emerged as the main contributor, accounting for 14.2% of the impact. This is relevant due to the manufacturing process involved. In the pulping process, the TET indicator for pulp production reached 1610 kg 1.4-DCB/tonne of pulp, with 56% of the impact was attributed to transportation. On the other hand, the FWET reached 22.5 kg 1.4-DCB/tonne of pulp, largely due to the electricity consumption (59%), followed by the chemical production process (26%). Similarly, electricity consumption accounted for 56% of the MET contribution, which reached 30.2 kg 1.4-DCB/tonne, followed by the production of chemical supplies.

- (g)

Human carcinogenic toxicity (HCT): In the forestry process, the HCT indicator reaches 0.589 kg 1.4-DCB/tonne of wood, with 86.6% coming from transport and machinery. In the pulping process, HCT reaches 107 kg 1.4-DCB/tonne of pulp, where waste treatment contributes 74% due to the disposal of dregs and grits in landfills during the causticisation stage. This elimination could generate some compounds and/or heavy metals contained as secondary pollutants, which could affect human and ecosystem health [

22].

- (h)

Water consumption (WC): the WC of the forest process is 0.176 m

3/tonne of wood. Approximately 60% of this water consumption can be attributed to the production processes of chemical supplies. Diammonium phosphate is the primary contributor, accounting for about 53% of the total water consumption. The production and operation of harvesters and forwarders also play a significant role, contributing 36.1% to the overall WC. In the pulping process, the WC increases to 44.5 m

3/tonne of pulp. This high-water consumption is primarily due to the process itself, accounting for 82% of the category. Specifically, water consumption in the process reaches around 36.1 m

3/tonne of cellulose (

Table 3). These findings highlight opportunities for improvement in terms of water use. Implementing the recirculation of certain flows, improving treatment systems, and preventing losses can effectively reduce water consumption. It is necessary to address these areas to enhance the sustainability of the forest process and promote more efficient water management practices [

49].

3.3. Global Process Comparison by Subsystem

The environmental profile of producing 1 tonne of bleached pulp is analysed in terms of contributions from the forestry and industrial systems (

Figure 4). Despite 2.6 tonnes of wood being used to produce 1 ADt, the forestry stage dominates the categories of SOD (79%) and MAEU (86%) due to the significant contribution of nitrous oxide and other nitrogen compounds resulting from the natural degradation of fertilizers and biocides used.

On the other hand, the pulping process contributes for over 88% in eight out of the remaining ten impact categories, with its most substantial contribution seen in HCT and WC (99%). In the case of HCT, leachate emissions from dregs and grits are the primary contributors, considering that, in Chile, landfill disposal is the final scenario for this waste. While efforts have been made to utilise this waste to improve acidified soils, its use is not yet widespread. Regarding WC, the pulping process itself is the main contributor. However, it should be noted that water consumption during the forestry phase was not included in this analysis due to a lack of representative information, highlighting a gap for improvement.

To effectively manage the environmental profile of white eucalyptus pulp production in Chile, it is imperative to focus on the resources required during the industrial stage. The results indicate that the highest direct emissions are generated by combustion equipment, particularly the recovery boiler and lime kiln, aligning with findings in existing literature [

7,

22,

24,

54,

55]. Key factors, such as the type of fuel used in these units, significantly influence the emissions generated. In addition, indirect emissions associated with the production of chemical supplies and the nature of the electricity used are crucial contributors that contribute to intensive resource consumption from both nature and the technosphere.

3.4. Discussion of Results

The study findings demonstrate that the pulp and mill stage have the greatest impact on various categories compared to the forestry stage. This aligns with the situation in Spain, where similar trends in environmental impact categories such as GWP, TA, MAEU, MET, and HCT are observed [

21].

The production and burning of fuels on-site (fuels and pulping) account for over 43% of the contribution in OF-HH and TA, which is consistent with the Spanish study [

21]. However, in Chile, the role of these activities is reduced in terms of GWP and SOD due to lower fuel oil requirements (−29.6%). This difference is partially compensated by the use of natural gas, although its significance in these categories is minor. The main contributor of GWP in Chilean pulping mills are electricity consumption (32%), primarily derived from coal (contributing 38%), chemical supplies (22%), such as sodium chlorate, (12.6% to the impact), and the pulping process itself (23%), in line previous literature [

21,

23]. The use of fossil energy is necessary for various stages of the pulping process, including the recovery boiler, biomass boiler, and lime kiln. In our study, all environmental burdens are allocated to the production of pulp, consistent with global data, which report a GWP of 779 kg CO

2eq/tonne of bleached pulp ECF [

22]. However, potential emissions reductions of up to 50% can be achieved by transitioning from fuel oil to natural gas [

20]. Furthermore, emission reduction strategies such as CO

2 separation in the recovery boiler, adsorption by calcium cycles, and oxy-combustion have been proposed [

26]. Alternative pulping processes, such as mechanical pulping and bio-pulping, do not offer better GWP profiles due to their higher energy requirements compared to Kraft pulp [

19].

Approximately 26% of the impacts in the OF-HH category are attributed to indirect emissions from coal and natural gas-fired power plants within the Chilean electricity matrix. The pulping process accounts for 43% of the impact in this category, mainly due to NH

3, NOx, and COV emissions specific to the site [

22]. Addressing these emissions can be achieved through combustion optimisation, reducing alkali content in consumed liquor, using low nitrogen fuel, employing gas recirculation, employing low NOx burners, and utilising burners with staged combustion [

56,

57].

In terms of the TA category, the main contributions in the pulping process come from the boiler and recovery boiler, followed by the kiln, due to the sulfur content of the biomass, black liquor, and fuel oil. This finding is consistent with previous studies [

20,

21,

30]. Switching to natural gas as the furnace’s fuel and implementing flue gas desulfurisation are potential methods to reduce the TA by approximately 75% [

20] and achieve a 95% efficiency in sulfur removal, respectively [

52].

The TET category in the pulping process is mainly related to wood transportation and the use of brake systems, which result in emissions with high metal content such as titanium, magnesium, and iron [

58]. This aspect has not been extensively covered in prior studies [

21]. FWET and MET account for over 56% of the impact related to electricity in the grid and its thermal power plants’ contribution (59%). However, due to significant differences in the electricity matrix between Chile and other countries in 2017, comparisons of these indicators are not consistent.

WC is highly dependent on the pulping process due to its extensive water requirements, with bleaching operations being the main contributor (over 80%). The adoption of Total Chlorine Free (TCF) sequences can reduce water consumption and the delivery of pollutants [

19,

21,

27].

The HCT category is dominated by waste treatment, particularly the disposal of grits and dregs from lime kilns, which produce secondary pollutants such as compounds and heavy metals. These pollutants have adverse effects on human health. In the forest stage, transportation and machinery contribute significantly to the 60% impact of the total transport and machinery impact, mainly due to the production of harvesters and their material demands (e.g., steel, iron, and electricity).

The GWP emissions in the forest stage are significantly higher than those reported in a previous study [

23]. This difference can be attributed to our study’s inclusion of the entire machinery and transport life cycle, expanding the system boundaries beyond just emissions from fossil fuel combustion in machinery aligned with previous research [

4,

23]. In addition, the use of nitrogen-based fertilisers accounts for over 25% of the total impact, attributed to fugitive emissions of N

2O [

13].

In the OF-HH category, machinery is the main contributor due to its emissions of non-full combustion gases during regular operations. The combustion of fuels also affects the TA category, but the major contribution is from diammonium phosphate and ternary fertilisers, which have an acidic residual effect on the soil [

46,

59]. To mitigate this effect, applying CaCO

3, along with a well-designed forest management plan, is recommended [

12,

48,

59]. These fertilisers also significantly affect the MAEU category, accounting for 99.5% of the overall impact, as they drain and leachate into the river basin before reaching the ocean.

3.5. Future Works and Recommendations

Despite this study encompassing most forestry facilities, some environmental aspects have not been included, such as water demand along with the growth of the trees in the forestry stage. Quantifying this issue is still necessary, and should consider factors such as species, location, climate, soil type, and nutrient availability. The recent forest fires in Chile have raised concerns about the water demands of Eucalyptus plantations as they are foreign species with a high-water requirement, leading to the obstruction of native vegetation and trees. Additionally, there is interest in exploring alternatives to replace chemical weed control and fertilisation with biodegradable or less harmful options.

On the other hand, the chemical processes in pulp and paper mills have several alternatives to enhance their performance, especially regarding some circular economy alternatives. These include incorporating solid waste into the construction sector [

60], utilising fly ashes [

61], recycling wastewater treatment sludge for metal extraction [

62], analysing process parameters to improve paper production efficiency [

63], and implementing waste-avoiding strategies based on circular economy principles [

64,

65,

66]. These opportunities for improvement in the Chilean pulp and paper industry are yet to be explored.

4. Conclusions

This study conducted a life cycle assessment to evaluate the environmental impacts associated with the production of bleached short-fibre cellulose in Chile, specifically focusing on the local production of Eucalyptus. The assessment followed a cradle-to-gate approach, considering both the silvicultural-forestry and subsequent industrial stages, including wood transportation to the plants.

The findings of the study revealed that the industrial stage contributed over 88% to eight out of ten impact categories, with significant contributions observed in the HCT (due to hazardous compounds from dregs and grits disposal) and WC (due to water consumption in pulping process) categories. Combustion operations, such as lime kiln and recovery boiler, emerged as the major contributors to categories like GWP, OF-HH, and TA. Additionally, the transportation of raw materials accounted for the largest share in the TET category. In the FWET and MET categories, the main contributions stemmed from fossil-based electricity consumption, followed by the production of chemical supplies.

In contrast, the forest stage had a significant contribution of 79% and 86% in the SOD and MAEU categories, respectively. These impacts were primarily attributed to the release of nutrients resulting from applying fertilisers and biocidal agents for weed control.

To effectively mitigate the environmental impacts associated with the production of bleached short-fibre cellulose in Chile, comprehensive management strategies throughout the value chain need to be implemented. This includes controlling the use of chemicals and machinery in forestry operations as well as considering the water demand in pulp mills. Moreover, addressing energy efficiency and chemical consumption in the pulping process and adopting circular economy strategies should be prioritised. By implementing effective management practices, the forestry-industrial consortium can evolve into an environmentally improved productive sector that meets the expectations of today’s society.