1. Introduction

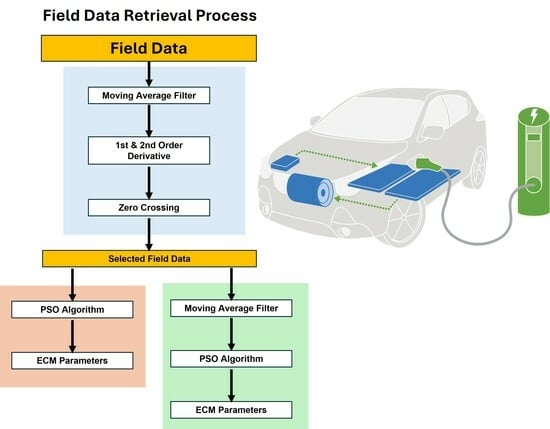

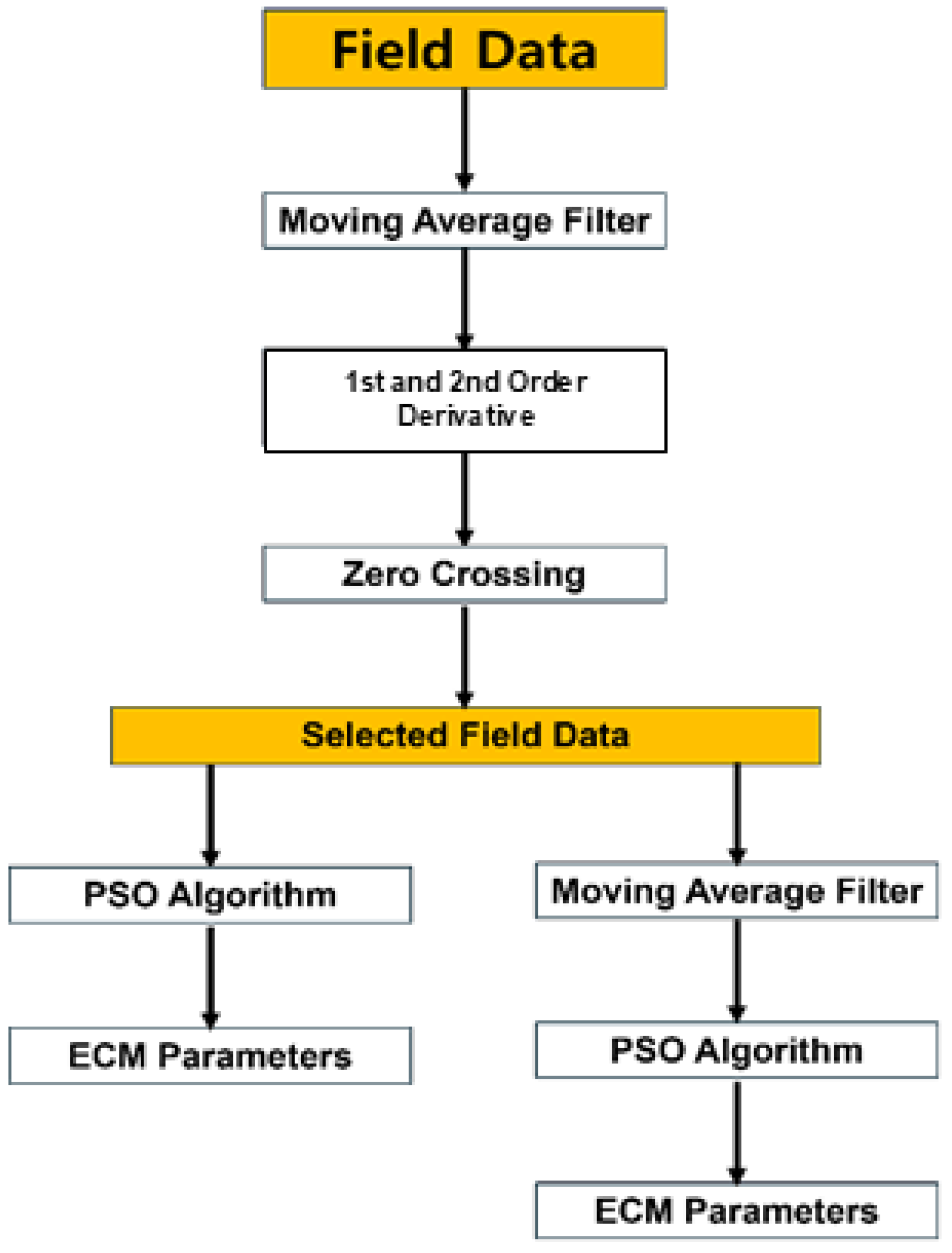

In this work, we introduce a novel method to collect field data dynamically while the electric vehicle is in motion under real-world running conditions. Instead of relying on predefined or long-term conditions, our approach ensures that data are gathered in real time during actual vehicle operation. We then apply a novel set of conditions to this dynamic field data to ensure that sufficient and relevant data segments are selected for estimating ECM parameters. In the first step, we removed the noise from filed data and then applied first- and second-order derivatives to determine the specific data set conditions. The data set was then collected using a zero-crossing method. Finally, the ECM parameters were estimated using the PSO algorithm. The current approach provides a more realistic representation of vehicle operation and enhances the accuracy of ECM parameter estimation.

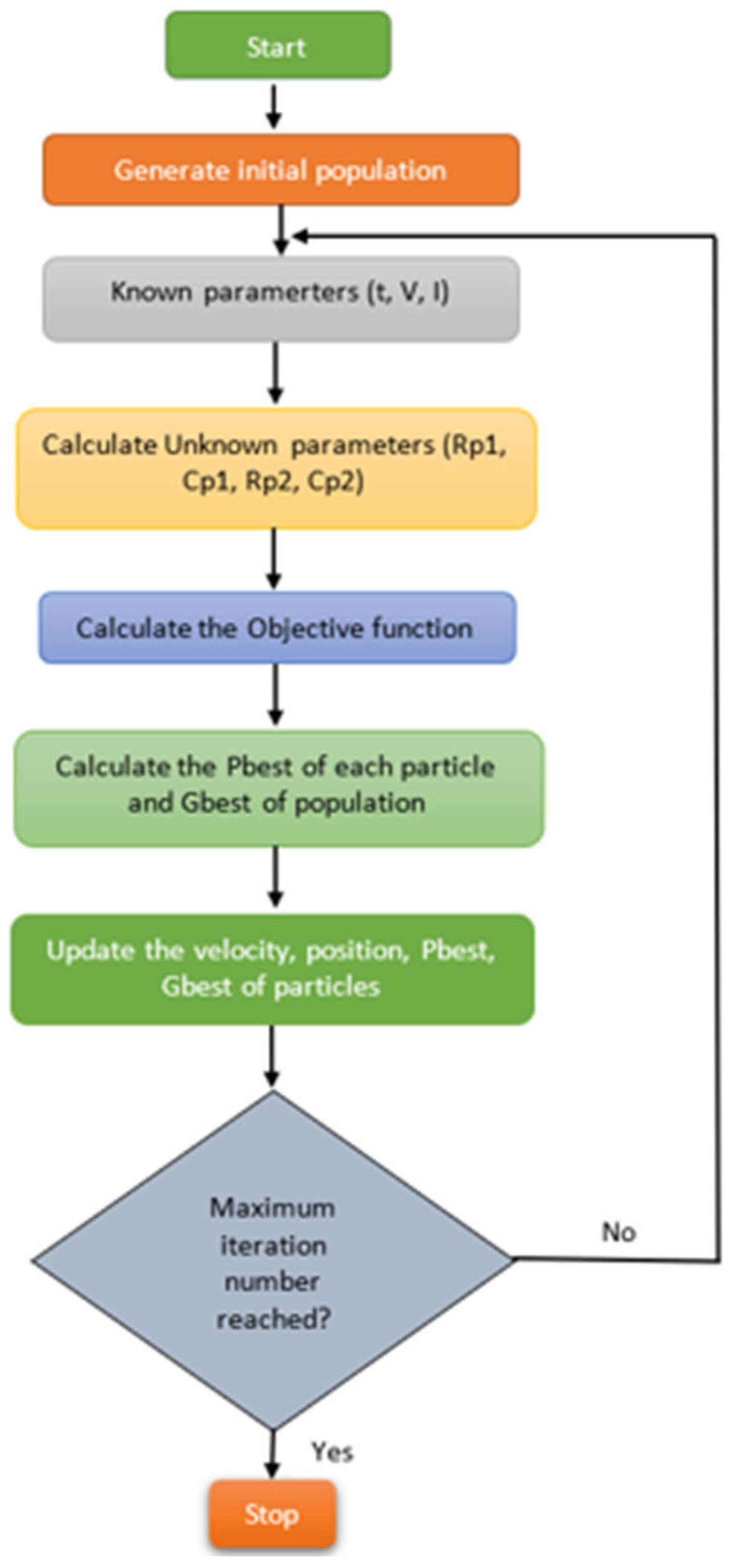

2. Fundamentals of PSO Algorithm

Equation (1) shows how a certain velocity will gradually become closer to Gbest and how to calculate Pbest. Equation (2) illustrates how to update the current position. where represents the current position of the particle, shows the updated particle position, refers to the current velocity, and indicates the updated velocity. Pbest is the best solution for the current particle, whereas Gbest is the best solution for all particles. w represents the weight of inertia, and the rand is set to produce random numbers between 0 and 1, with and indicating positive constants.

The selection of these parameters plays a crucial role in determining the algorithm’s performance. Fine-tuning the parameters often leads to the best performance for a specific problem. Generally, the inertia weight (w) typically decreases from 0.9 to 0.4 to transition from a global to local search. The cognitive (c1) and social (c2) coefficients, usually set to 2, control individual and group learning. Swarm size (20–100 particles) and velocity limits are adjusted based on the problem, while stopping criteria like iteration limits or convergence thresholds ensure efficiency. The fine-tuning of the parameters can also be performed through trial-and-error methods. The PSO algorithm’s ability to find an optimal or near-optimal solution over time is known as convergence analysis. The convergence analysis depends on the balance between exploration (high inertia, and large swarm) and exploitation (low inertia, and high cognitive/social coefficients). Careful tuning avoids premature convergence and ensures efficient search.

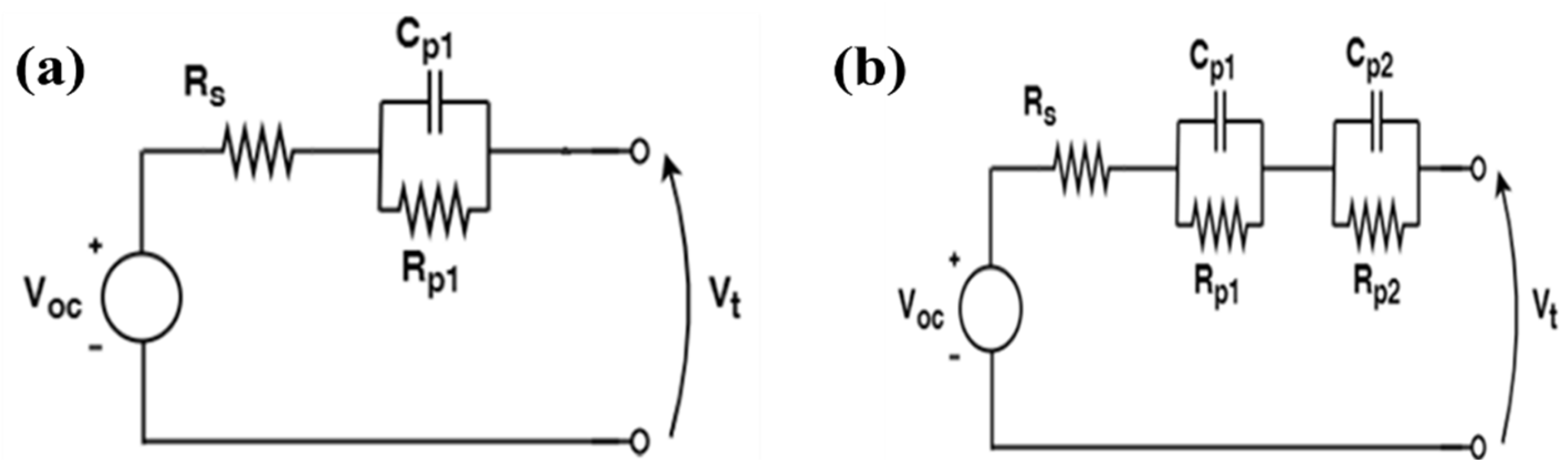

3. ECM for Lithium-Ion Batteries

The main parameters of the ECM, such as ohmic resistance (Rs), polarization resistance (Rp), and polarization capacitance (Cp), have distinct physical significance. Rs accounts for the resistance of the battery’s internal components, such as the electrolyte, current collectors, and internal connections, and increases with temperature and battery aging. Rp shows the internal leakage current due to side reactions in the battery, and it often decreases with SoC and deteriorates with battery aging. Cp represents the ability of the battery to store charge at a given voltage and shows electrochemical behavior at the battery’s electrodes. The Cp varies with SoC (increases with higher SoC), temperature, and the specific battery chemistry. Overall, these parameters detect the degradation of the battery, such as reduced capacity and efficiency under different charge/discharge conditions.

First and Second-Order RC Circuit

where .

4. Proposed Methodology for Collecting Data

4.1. Experimental Data

4.2. Proposed Methodology for Retrieving Field Data

5. Results and Validation

5.1. Simulation

where , and indicates the measured ECM voltage.

where y = Voltage, x = time.

5.2. Results for Field Data

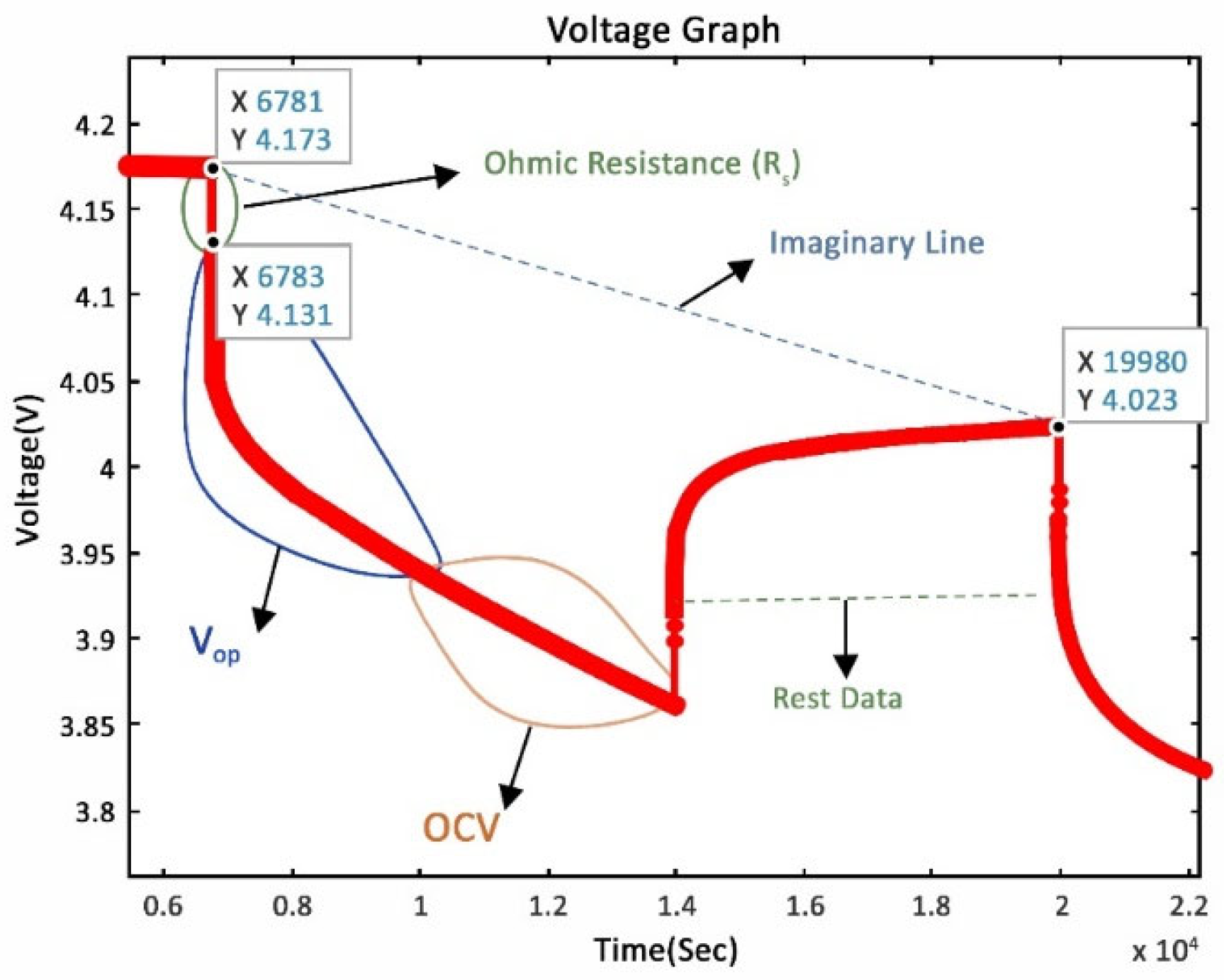

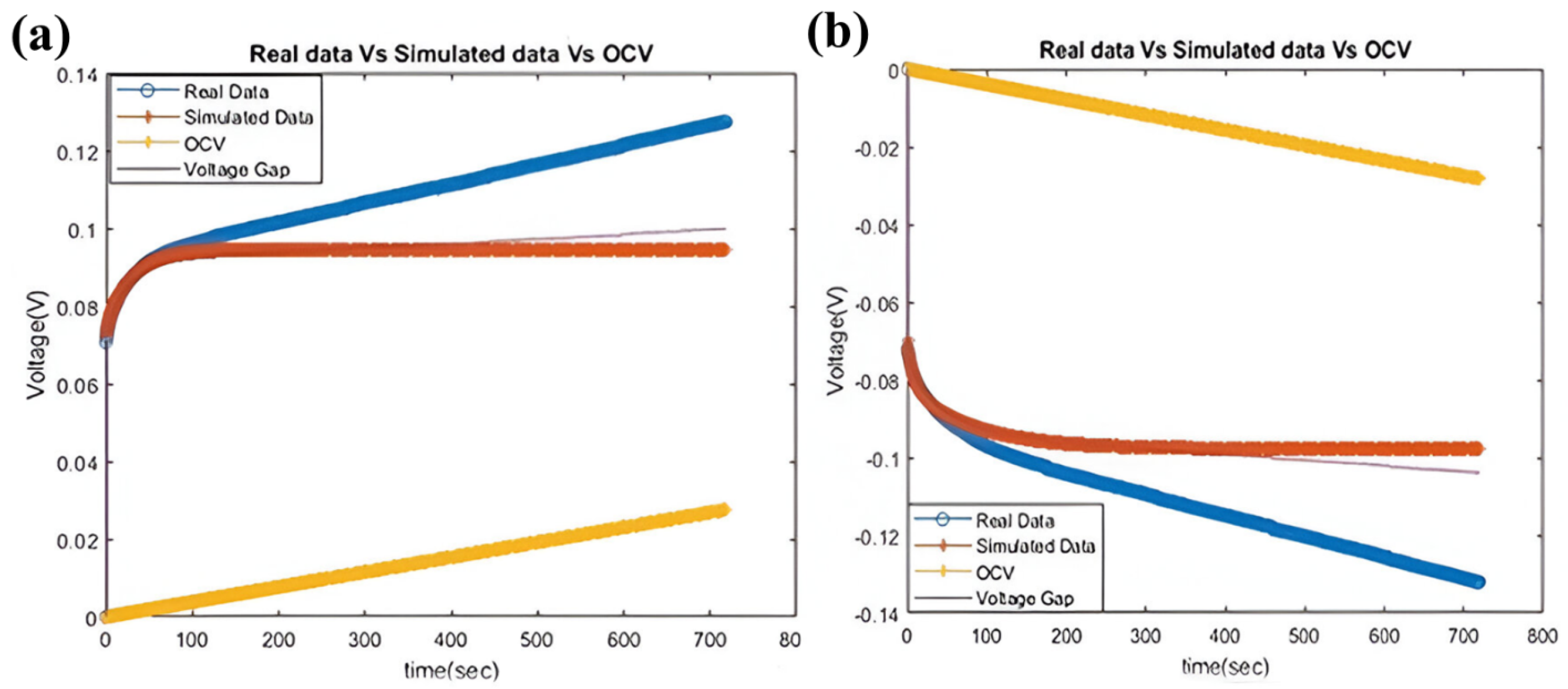

where , OCV is the open circuit voltage, and Rs is the ohmic resistance.

6. Discussion

The proposed method has significant potential for the accurate and reliable parameter estimation of ECMs. Particularly, it is valuable for real-time battery management systems BMS in EVs, where accurate estimation of battery states, such as SoC and SoH, are critical for ensuring safety, optimizing performance, and extending battery life. Furthermore, the PSO algorithm enhances the precision of ECMs, even under running battery conditions. This makes the method applicable not only to conventional EV batteries but also to other advanced energy storage systems, such as hybrid electric vehicles and stationary energy storage units. Additionally, the flexibility of the proposed approach allows it to adapt to various battery systems and charging/discharging strategies, which will further expand its practical utility. A key strength of our work lies in the validation of the retrieved and estimated parameters through comprehensive curve fitting against real-world field data. This demonstrates the theoretical performance and practical applicability of the proposed. By addressing key challenges in battery modeling, this study provides a foundation for improving the efficiency and reliability of next-generation energy management systems.

Despite the promising outcomes, the proposed data retrieval method has some sensitive factors and limitations. Primarily, the noise filtering process, zero-crossing threshold, data selection conditions, and the parameters of the PSO algorithm are sensitive factors for this study. These factors require careful tuning and consideration, as improper settings can significantly degrade performance and lead to inaccurate results. For example, the noise removal process depends on the window size of the moving-average filter; a larger window size makes data oversmooth, and a smaller window may fail to reduce noise. Similarly, the improper zero-crossing threshold selection can lead to either missed crossings or the inclusion of irrelevant ones. The data selection conditions are also critical because the minimum number of points or time intervals may exclude useful data, while lenient conditions might allow noisy or irrelevant data to affect parameter estimation. Additionally, as we discussed earlier, the PSO algorithm used for parameter estimation inherently introduces approximation-based error, which is the main limitation of this method. In our work, this error is around 2% which might be further reduced by improving the optimization algorithm using a hybrid algorithm method or including additional factors, such as temperature and battery aging. Future work aims to address these issues to allow for a more accurate representation of real-world operating conditions and provide a more environmentally adaptive framework.

7. Conclusions

This paper proposes an efficient method to estimate the ECM parameters (Rp and Cp) from the field data (voltage, current, and time). Firstly, the noise from field data was removed using a moving average filter. After that first- and second-order derivations are applied to the filtered data to determine a specific data set of conditions and then introduce a novel zero-crossing technique for retrieving meaningful data segments. The selected field data were then analyzed using a second-order RC model. Finally, a PSO algorithm has been adapted to estimate the parameters of the SORC. It was concluded that the error between simulation and real voltage is less than 2% (calculated above 100 points), which signifies that the PSO is a better parameter identification approach than others. However, this error can be further reduced by improving the filtering method and optimization algorithm by using the hybrid algorithm. Furthermore, including temperature and battery aging in the modeling process can enhance the reliability and applicability of the proposed method. Looking ahead, we plan to focus on the hybrid approach and incorporate temperature and battery aging factors into our model to further enhance its accuracy. These additions will allow the ECM parameters to accurately estimate the state of the battery for long-term battery performance and environmental influences, making it more applicable for real-world applications.

Author Contributions

Conceptualization, S.A.S.; methodology, S.A.S.; software, S.A.S. and S.I.; validation, S.I. and J.P.; formal analysis, S.A.S. and S.H.; investigation, S.H. and W.Y.K.; resources, S.H. and J.P.; data curation, S.A.S. and S.H.; writing—original draft preparation, S.A.S. and J.P.; writing—review and editing, S.I., S.H. and W.Y.K.; visualization, S.A.S.; supervision, S.H. and W.Y.K.; project administration, S.H. and W.Y.K.; funding acquisition, W.Y.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the “Regional Innovation Strategy (RIS)” through the National Research Foundation of Korea (NRF), funded by the Ministry of Education (MOE) (2023-RIS009).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Barr, A.; Suard, F.; Gérard, M.; Riu, D. A Real-time Data-driven Method for Battery Health Prognostics in Electric Vehicle Use. PHM Soc. Eur. Conf. 2014, 2, 1–8. [Google Scholar] [CrossRef]

- Patil, P. Innovations in electric vehicle technology: A review of emerging trends and their potential impacts on transportation and society. Rev. Contemp. Bus. Anal. 2021, 4, 1–13. [Google Scholar]

- Dik, A.; Omer, S.; Boukhanouf, R. Electric Vehicles: V2G for Rapid, Safe, and Green EV Penetration. Energies 2022, 15, 803. [Google Scholar] [CrossRef]

- See, K.; Wang, G.; Zhang, Y.; Wang, Y.; Meng, L.; Gu, X.; Zhang, N.; Lim, K.; Zhao, L.; Xie, B. Critical review and functional safety of a battery management system for large-scale lithium-ion battery pack technologies. Int. J. Coal Sci. Technol. 2022, 9, 36. [Google Scholar] [CrossRef]

- Gabbar, H.A.; Othman, A.M.; Abdussami, M.R. Review of Battery Management Systems (BMS) Development and Industrial Standards. Technologies 2021, 9, 28. [Google Scholar] [CrossRef]

- Hu, X.; Feng, F.; Liu, K.; Zhang, L.; Xie, J.; Liu, B. State estimation for advanced battery management: Key challenges and future trends. Renew. Sustain. Energy Rev. 2019, 114, 109334. [Google Scholar] [CrossRef]

- Ungurean, L.; Cârstoiu, G.; Micea, M.V.; Groza, V. Battery state of health estimation: A structured review of models, methods and commercial devices. Int. J. Energy Res. 2017, 41, 151–181. [Google Scholar] [CrossRef]

- Li, Y.; Stroe, D.-I.; Cheng, Y.; Sheng, H.; Sui, X.; Teodorescu, R. On the feature selection for battery state of health estimation based on charging–discharging profiles. J. Energy Storage 2021, 33, 102122. [Google Scholar] [CrossRef]

- Shen, P.; Ouyang, M.; Lu, L.; Li, J.; Feng, X. The co-estimation of state of charge, state of health, and state of function for lithium-ion batteries in electric vehicles. IEEE Trans. Veh. Technol. 2017, 67, 92–103. [Google Scholar] [CrossRef]

- Ma, L.; Hu, C.; Cheng, F. State of charge and state of energy estimation for lithium-ion batteries based on a long short-term memory neural network. J. Energy Storage 2021, 37, 102440. [Google Scholar] [CrossRef]

- Ouyang, D.; Weng, J.; Chen, M.; Wang, J.; Wang, Z. Sensitivities of lithium-ion batteries with different capacities to overcharge/over-discharge. J. Energy Storage 2022, 52, 104997. [Google Scholar] [CrossRef]

- Chen, S.; Fan, G.; Wang, Y.; Zhou, B.; Ye, S.; Liu, Y.; Guo, B.; Zhu, C.; Zhang, X. The impact of intermittent overcharging on battery capacity and reliability: Electrochemical performance analysis and failure prediction. J. Power Sources 2024, 591, 233800. [Google Scholar] [CrossRef]

- Xiong, R.; Cao, J.; Yu, Q.; He, H.; Sun, F. Critical Review on the Battery State of Charge Estimation Methods for Electric Vehicles. IEEE Access 2018, 6, 1832–1843. [Google Scholar] [CrossRef]

- Zheng, Y.; Ouyang, M.; Han, X.; Lu, L.; Li, J. Investigating the error sources of the online state of charge estimation methods for lithium-ion batteries in electric vehicles. J. Power Sources 2018, 377, 161–188. [Google Scholar] [CrossRef]

- Adaikkappan, M.; Sathiyamoorthy, N. Modeling, state of charge estimation, and charging of lithium-ion battery in electric vehicle: A review. Int. J. Energy Res. 2022, 46, 2141–2165. [Google Scholar] [CrossRef]

- How, D.N.; Hannan, M.; Lipu, M.H.; Ker, P.J. State of charge estimation for lithium-ion batteries using model-based and data-driven methods: A review. IEEE Access 2019, 7, 136116–136136. [Google Scholar] [CrossRef]

- Shrivastava, P.; Soon, T.K.; Idris, M.Y.I.B.; Mekhilef, S. Overview of model-based online state-of-charge estimation using Kalman filter family for lithium-ion batteries. Renew. Sustain. Energy Rev. 2019, 113, 109233. [Google Scholar] [CrossRef]

- Li, B.; Bei, S. Estimation algorithm research for lithium battery SOC in electric vehicles based on adaptive unscented Kalman filter. Neural Comput. Appl. 2019, 31, 8171–8183. [Google Scholar] [CrossRef]

- Naseri, F.; Schaltz, E.; Stroe, D.-I.; Gismero, A.; Farjah, E. An enhanced equivalent circuit model with real-time parameter identification for battery state-of-charge estimation. IEEE Trans. Ind. Electron. 2021, 69, 3743–3751. [Google Scholar] [CrossRef]

- Pozzato, G.; Allam, A.; Pulvirenti, L.; Negoita, G.A.; Paxton, W.A.; Onori, S. Analysis and key findings from real-world electric vehicle field data. Joule 2023, 7, 2035–2053. [Google Scholar] [CrossRef]

- Nachimuthu, S.; Alsaif, F.; Devarajan, G.; Vairavasundaram, I. Real time SOC estimation for Li-ion batteries in Electric vehicles using UKBF with online parameter identification. Sci. Rep. 2025, 15, 1714. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Tian, J.; Sun, Z.; Wang, L.; Xu, R.; Li, M.; Chen, Z. A comprehensive review of battery modeling and state estimation approaches for advanced battery management systems. Renew. Sustain. Energy Rev. 2020, 131, 110015. [Google Scholar] [CrossRef]

- Tian, A.; Dong, K.; Yang, X.-G.; Wang, Y.; He, L.; Gao, Y.; Jiang, J. Physics-based parameter identification of an electrochemical model for lithium-ion batteries with two-population optimization method. Appl. Energy 2025, 378, 124748. [Google Scholar] [CrossRef]

- Yavuz, H.; Akyildiz, A.; Gulbahce, M.O. A Comprehensive Review of Physics-Based Battery Models and Comparing Different Physics-Based Models for Various Chemistries. Turk. J. Electr. Power Energy Syst. 2024, 4, 108–117. [Google Scholar] [CrossRef]

- Su, J.; Lin, M.; Wang, S.; Li, J.; Coffie-Ken, J.; Xie, F. An equivalent circuit model analysis for the lithium-ion battery pack in pure electric vehicles. Meas. Control 2019, 52, 193–201. [Google Scholar] [CrossRef]

- Tran, M.-K.; Mathew, M.; Janhunen, S.; Panchal, S.; Raahemifar, K.; Fraser, R.; Fowler, M. A comprehensive equivalent circuit model for lithium-ion batteries, incorporating the effects of state of health, state of charge, and temperature on model parameters. J. Energy Storage 2021, 43, 103252. [Google Scholar] [CrossRef]

- Kara, A. A data-driven approach based on deep neural networks for lithium-ion battery prognostics. Neural Comput. Appl. 2021, 33, 13525–13538. [Google Scholar] [CrossRef]

- Li, W.; Demir, I.; Cao, D.; Jöst, D.; Ringbeck, F.; Junker, M.; Sauer, D.U. Data-driven systematic parameter identification of an electrochemical model for lithium-ion batteries with artificial intelligence. Energy Storage Mater. 2022, 44, 557–570. [Google Scholar] [CrossRef]

- Xuan, L.; Qian, L.; Chen, J.; Bai, X.; Wu, B. State-of-charge prediction of battery management system based on principal component analysis and improved support vector machine for regression. IEEE Access 2020, 8, 164693–164704. [Google Scholar] [CrossRef]

- Bhushan, N.; Mekhilef, S.; Tey, K.S.; Shaaban, M.; Seyedmahmoudian, M.; Stojcevski, A. Overview of model-and non-model-based online battery management systems for electric vehicle applications: A comprehensive review of experimental and simulation studies. Sustainability 2022, 14, 15912. [Google Scholar] [CrossRef]

- Hussein, H.M.; Aghmadi, A.; Abdelrahman, M.S.; Rafin, S.S.H.; Mohammed, O. A review of battery state of charge estimation and management systems: Models and future prospective. Wiley Interdiscip. Rev. Energy Environ. 2024, 13, e507. [Google Scholar]

- Gao, Y.; Zhu, C.; Zhang, X.; Guo, B. Implementation and evaluation of a practical electrochemical-thermal model of lithium-ion batteries for EV battery management system. Energy 2021, 221, 119688. [Google Scholar] [CrossRef]

- Ren, B.; Xie, C.; Sun, X.; Zhang, Q.; Yan, D. Parameter identification of a lithium-ion battery based on the improved recursive least square algorithm. IET Power Electron. 2020, 13, 2531–2537. [Google Scholar] [CrossRef]

- Camboim, M.M.; Moreira, A.C.; Giesbrecht, M. Parameter Estimation of Second-Life Lithium-Ion Batteries Through Subspace Identification Methods. In Proceedings of the 2023 IEEE 32nd International Symposium on Industrial Electronics (ISIE), Helsinki, Finland, 19–21 June 2023; pp. 1–6. [Google Scholar]

- Zhu, H.; Liu, Y.; Zhao, C. Parameter identification and SOC estimation of lithium ion battery. Hunan Daxue Xuebao/J. Hunan Univ. Nat. Sci. 2014, 41, 37–42. [Google Scholar]

- Hong, J.; Wang, Z.; Chen, W.; Wang, L.-Y.; Qu, C. Online joint-prediction of multi-forward-step battery SOC using LSTM neural networks and multiple linear regression for real-world electric vehicles. J. Energy Storage 2020, 30, 101459. [Google Scholar] [CrossRef]

- Tamilselvi, S.; Gunasundari, S.; Karuppiah, N.; Razak RK, A.; Madhusudan, S.; Nagarajan, V.M.; Sathish, T.; Shamim, M.Z.M.; Saleel, C.A.; Afzal, A. A review on battery modelling techniques. Sustainability 2021, 13, 10042. [Google Scholar] [CrossRef]

- Feng, F.; Hu, X.; Hu, L.; Hu, F.; Li, Y.; Zhang, L. Propagation mechanisms and diagnosis of parameter inconsistency within Li-Ion battery packs. Renew. Sustain. Energy Rev. 2019, 112, 102–113. [Google Scholar] [CrossRef]

- Kennedy, J.; Eberhart, R. Particle swarm optimization. In Proceedings of the ICNN’95-International Conference on Neural Networks, Perth, WA, Australia, 27 November–1 December 1995; pp. 1942–1948. [Google Scholar]

- Usama, M.; Kim, J. Model-free current control solution employing intelligent control for enhanced motor drive performance. Sci. Rep. 2025, 15, 60. [Google Scholar] [CrossRef]

- Wang, D.; Tan, D.; Liu, L. Particle swarm optimization algorithm: An overview. Soft Comput. 2018, 22, 387–408. [Google Scholar] [CrossRef]

- Jusoh, M.A.; Daud, M.Z. Accurate battery model parameter identification using heuristic optimization. Int. J. Power Electron. Drive Syst. 2020, 11, 333. [Google Scholar] [CrossRef]

- Lambora, A.; Gupta, K.; Chopra, K. Genetic algorithm-A literature review. In Proceedings of the 2019 International Conference on Machine Learning, Big Data, Cloud and Parallel Computing (COMITCon), Faridabad, India, 14–16 February 2019; pp. 380–384. [Google Scholar]

- Fatima Brondani, M.d.; Sausen, A.T.Z.R.; Sausen, P.S.; Binelo, M.O. Parameter estimation of lithium ion polymer battery mathematical model using genetic algorithm. Comput. Appl. Math. 2018, 37, 296–313. [Google Scholar] [CrossRef]

- Ou, C.; Lin, W. Comparison between PSO and GA for parameters optimization of PID controller. In Proceedings of the 2006 International Conference on Mechatronics and Automation, Luoyang, China, 15–18 June 2006; pp. 2471–2475. [Google Scholar]

- Kachitvichyanukul, V. Comparison of three evolutionary algorithms: GA, PSO, and DE. Ind. Eng. Manag. Syst. 2012, 11, 215–223. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, S.; Ji, G. A comprehensive survey on particle swarm optimization algorithm and its applications. Math. Probl. Eng. 2015, 2015, 931256. [Google Scholar] [CrossRef]

- Noel, M.M. A new gradient based particle swarm optimization algorithm for accurate computation of global minimum. Appl. Soft Comput. 2012, 12, 353–359. [Google Scholar] [CrossRef]

- Eberhart, R.; Kennedy, J. A new optimizer using particle swarm theory. In Proceedings of the MHS’95 Sixth International Symposium on Micro Machine and Human Science, Nagoya, Japan, 4–6 October 1995; pp. 39–43. [Google Scholar]

- Wen, C.; Ling, W.; Ren, X. General particle swarm optimization algorithm. In Proceedings of the 2023 IEEE 2nd International Conference on Electrical Engineering, Big Data and Algorithms (EEBDA), Changchun, China, 24–26 February 2023; pp. 1204–1208. [Google Scholar]

- Song, L.; Zhang, K.; Liang, T.; Han, X.; Zhang, Y. Intelligent state of health estimation for lithium-ion battery pack based on big data analysis. J. Energy Storage 2020, 32, 101836. [Google Scholar] [CrossRef]

- D Pranav, O.; Babu, P.S.; Indragandhi, V.; Ashok, B.; Vedhanayaki, S.; Kavitha, C. Enhanced SOC estimation of lithium ion batteries with RealTime data using machine learning algorithms. Sci. Rep. 2024, 14, 16036. [Google Scholar] [CrossRef]

- Jaberipour, M.; Khorram, E.; Karimi, B. Particle swarm algorithm for solving systems of nonlinear equations. Comput. Math. Appl. 2011, 62, 566–576. [Google Scholar] [CrossRef]

- Wang, S.; Zhou, F.; Wang, F. Effect of Inertia Weight w on PSO-SA Algorithm. Int. J. Online Biomed. Eng. (Ijoe) 2013, 9, 87–91. [Google Scholar] [CrossRef]

- Eberhart, R.C.; Shi, Y. Comparing inertia weights and constriction factors in particle swarm optimization. In Proceedings of the 2000 Congress on Evolutionary Computation. CEC00 (Cat. No. 00TH8512), La Jolla, CA, USA, 16–19 July 2000; pp. 84–88. [Google Scholar]

- Thakkar, R.R.; Rao, Y.S.; Sawant, R.R. Performance Analysis of Electrical Equivalent Circuit Models of Lithium-ion Battery. In Proceedings of the 2020 IEEE Pune Section International Conference (PuneCon), Pune, India, 16–18 December 2020; pp. 103–107. [Google Scholar]

- Rushali, R.T. Electrical Equivalent Circuit Models of Lithium-ion Battery. In Management and Applications of Energy Storage Devices; Kenneth, E.O., Ed.; IntechOpen: Rijeka, Croatia, 2021; Chapter 1. [Google Scholar] [CrossRef]

- Rukavina, F.; Leko, D.; Matijašić, M.; Bralić, I.; Ugalde, J.M.; Vašak, M. Identification of Equivalent Circuit Model Parameters for a Li-ion Battery Cell. In Proceedings of the 2023 IEEE 11th International Conference on Systems and Control (ICSC), Sousse, Tunisia, 18–20 December 2023; pp. 671–676. [Google Scholar]

- Tran, M.-K.; DaCosta, A.; Mevawalla, A.; Panchal, S.; Fowler, M. Comparative Study of Equivalent Circuit Models Performance in Four Common Lithium-Ion Batteries: LFP, NMC, LMO, NCA. Batteries 2021, 7, 51. [Google Scholar] [CrossRef]

- Santos, R.M.S.; Alves, C.L.G.d.S.; Macedo, E.C.T.; Villanueva, J.M.M.; Hartmann, L.V. Estimation of lithium-ion battery model parameters using experimental data. In Proceedings of the 2017 2nd International Symposium on Instrumentation Systems, Circuits and Transducers (INSCIT), Fortaleza, Brazil, 28 August–1 September 2017; pp. 1–6. [Google Scholar]

- Yang, J.; Cai, Y.; Pan, C.; Mi, C. A novel resistor-inductor network-based equivalent circuit model of lithium-ion batteries under constant-voltage charging condition. Appl. Energy 2019, 254, 113726. [Google Scholar] [CrossRef]

- Li, W.; Cao, D.; Jöst, D.; Ringbeck, F.; Kuipers, M.; Frie, F.; Sauer, D.U. Parameter sensitivity analysis of electrochemical model-based battery management systems for lithium-ion batteries. Appl. Energy 2020, 269, 115104. [Google Scholar] [CrossRef]

- Liu, K.; Gao, Y.; Zhu, C.; Li, K.; Fei, M.; Peng, C.; Zhang, X.; Han, Q.-L. Electrochemical modeling and parameterization towards control-oriented management of lithium-ion batteries. Control Eng. Pract. 2022, 124, 105176. [Google Scholar] [CrossRef]

- Xie, N.; Zhao, W.; Lin, W.; Chen, Y.; Wang, Z.; Xuan, Y. A Method for Measuring Electrochemical Impedance Spectroscopy in High-voltage Battery Systems. In Proceedings of the 2024 International Conference on Energy and Electrical Engineering (EEE), Nanchang, China, 5–6 July 2024; pp. 1–5. [Google Scholar]

- Chen, M.; Rincon-Mora, G.A. Accurate electrical battery model capable of predicting runtime and IV performance. IEEE Trans. Energy Convers. 2006, 21, 504–511. [Google Scholar] [CrossRef]

- Wall, R.W. Simple methods for detecting zero crossing. In Proceedings of the IECON’03. 29th Annual Conference of the IEEE Industrial Electronics Society (IEEE Cat. No.03CH37468), Roanoke, VA, USA, 2–6 November 2003. [Google Scholar]

- Syed Adil, S.; Sekyung, H. Equivalent Circuit Model Parameters Fitting Using Particle Swarm Optimization. In Proceedings of the 51st Korean Institute of Electrical Engineers Summer Conference, Busan, Republic of Korea, 15–17 July 2020. [Google Scholar]

- Hariharan, K.S.; Senthil Kumar, V. A nonlinear equivalent circuit model for lithium ion cells. J. Power Sources 2013, 222, 210–217. [Google Scholar] [CrossRef]

- Pierce, R.; Stacey, K.; Bardini, C. Linear functions: Teaching strategies and students’ conceptions associated with y= mx+ c. Pedagog. Int. J. 2010, 5, 202–215. [Google Scholar] [CrossRef]

- Sangwan, V.; Kumar, R.; Rathore, A.K. Estimation of battery parameters of the equivalent circuit model using Grey Wolf Optimization. In Proceedings of the 2016 IEEE 6th International Conference on Power Systems (ICPS), New Delhi, India, 4–6 March 2016; pp. 1–6. [Google Scholar]

Fundamental concept of PSO.

Figure 1.

Fundamental concept of PSO.

(a) ECM with FORC and (b) ECM with FORC and SORC.

Figure 2.

(a) ECM with FORC and (b) ECM with FORC and SORC.

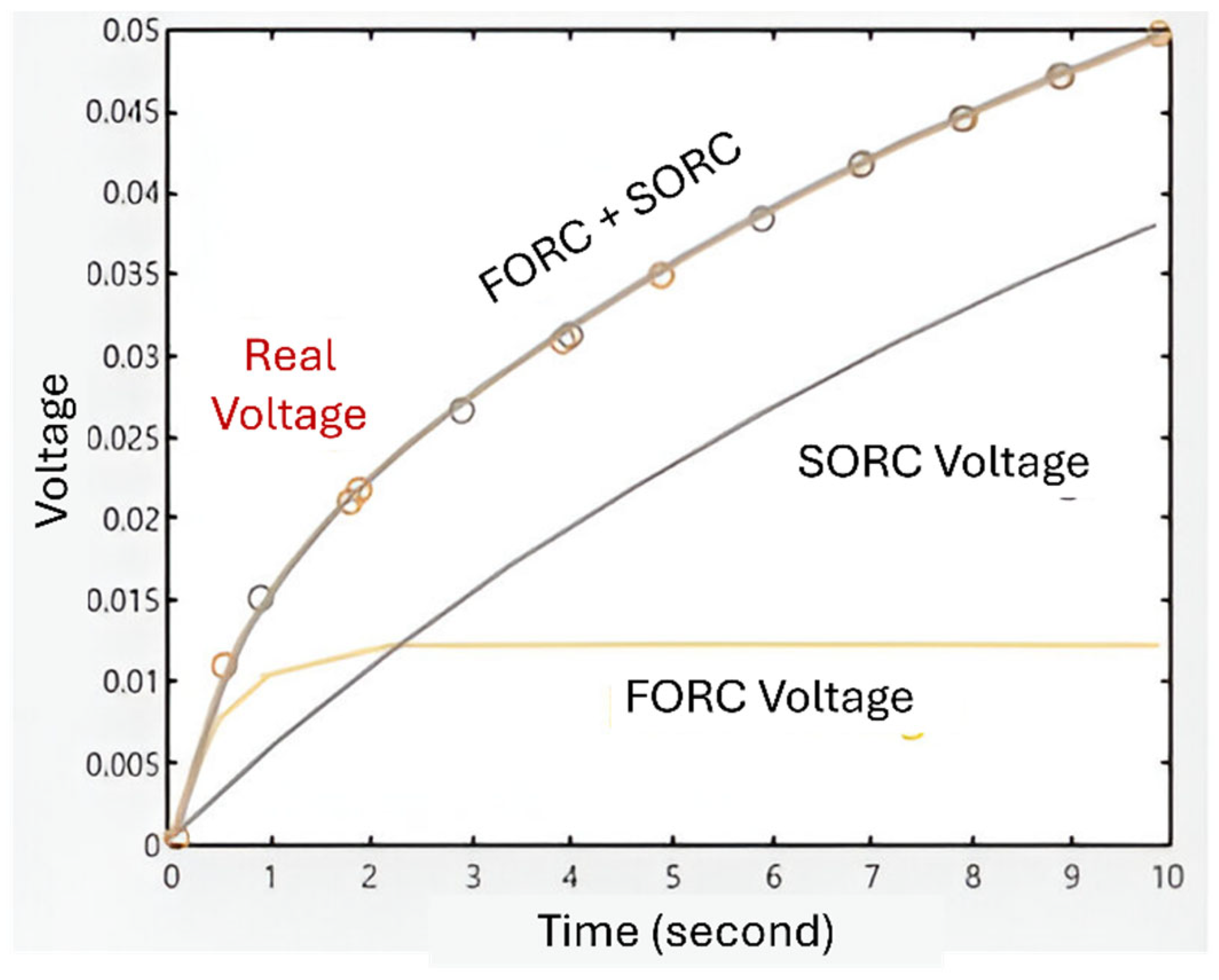

Comparison of the output from the FORC and SORC models.

Figure 3.

Comparison of the output from the FORC and SORC models.

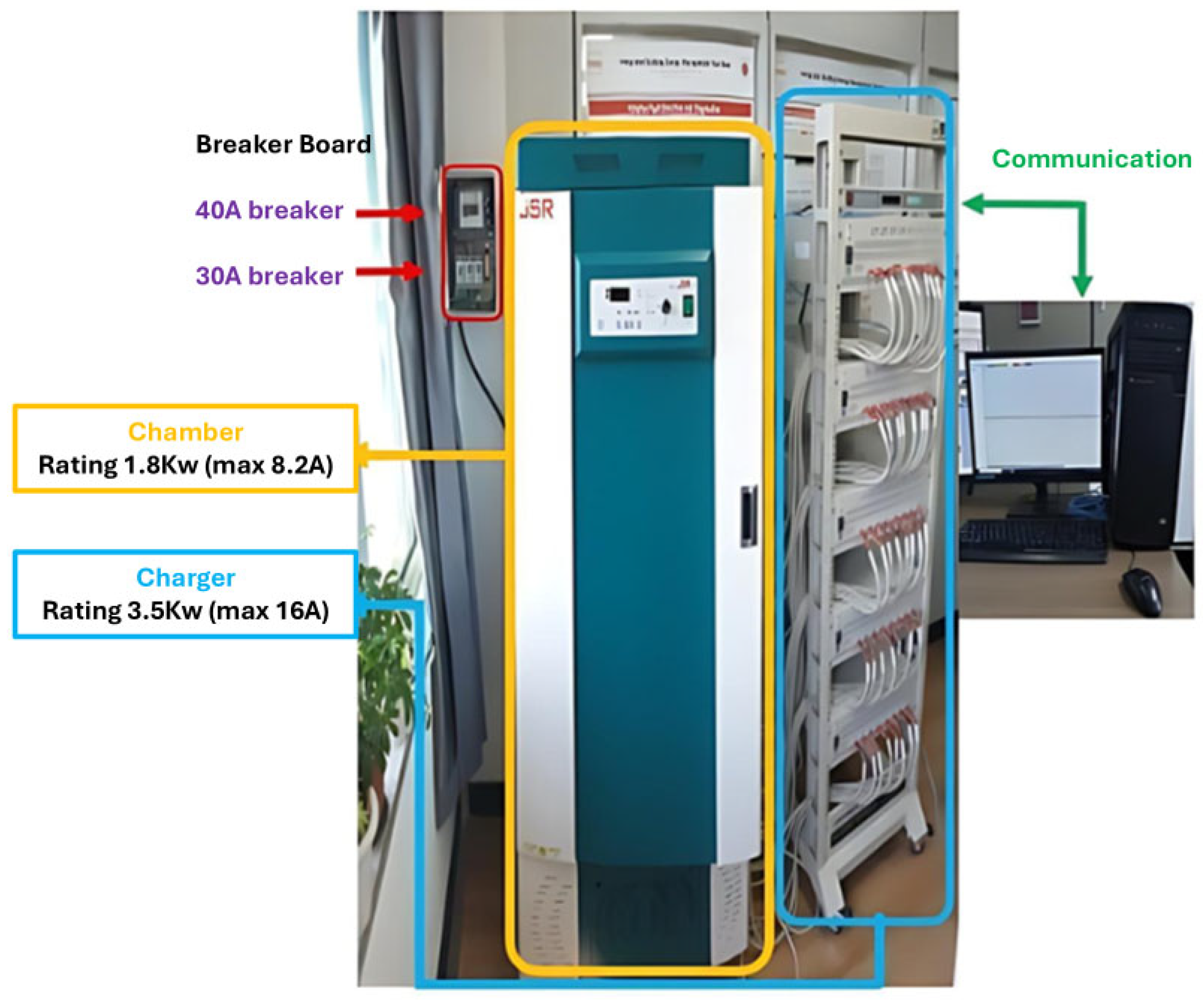

Battery tester setup (BT).

Figure 4.

Battery tester setup (BT).

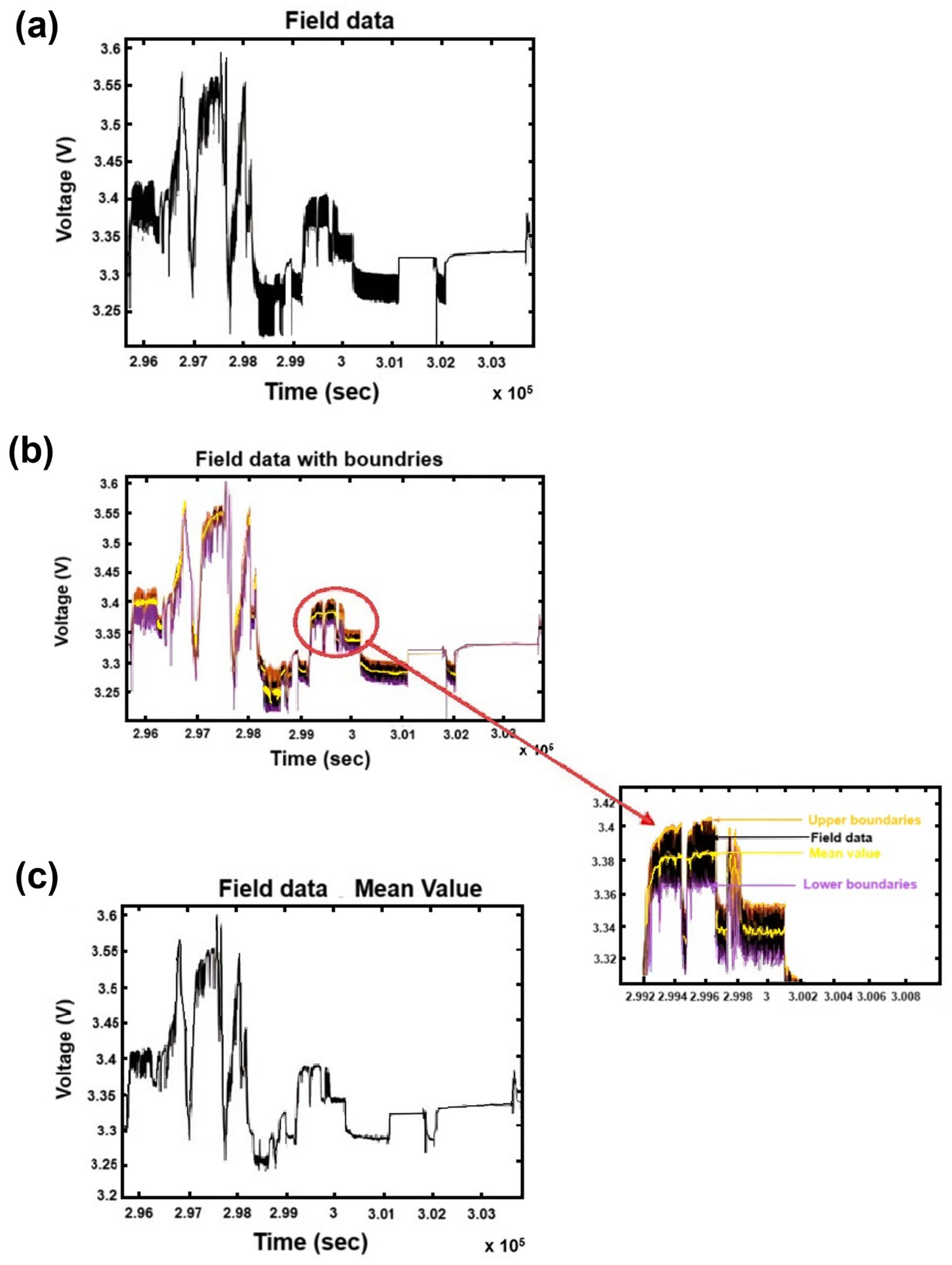

(a) Field data; (b) field data with moving_avg function; (c) field data after noise is removed.

Figure 5.

(a) Field data; (b) field data with moving_avg function; (c) field data after noise is removed.

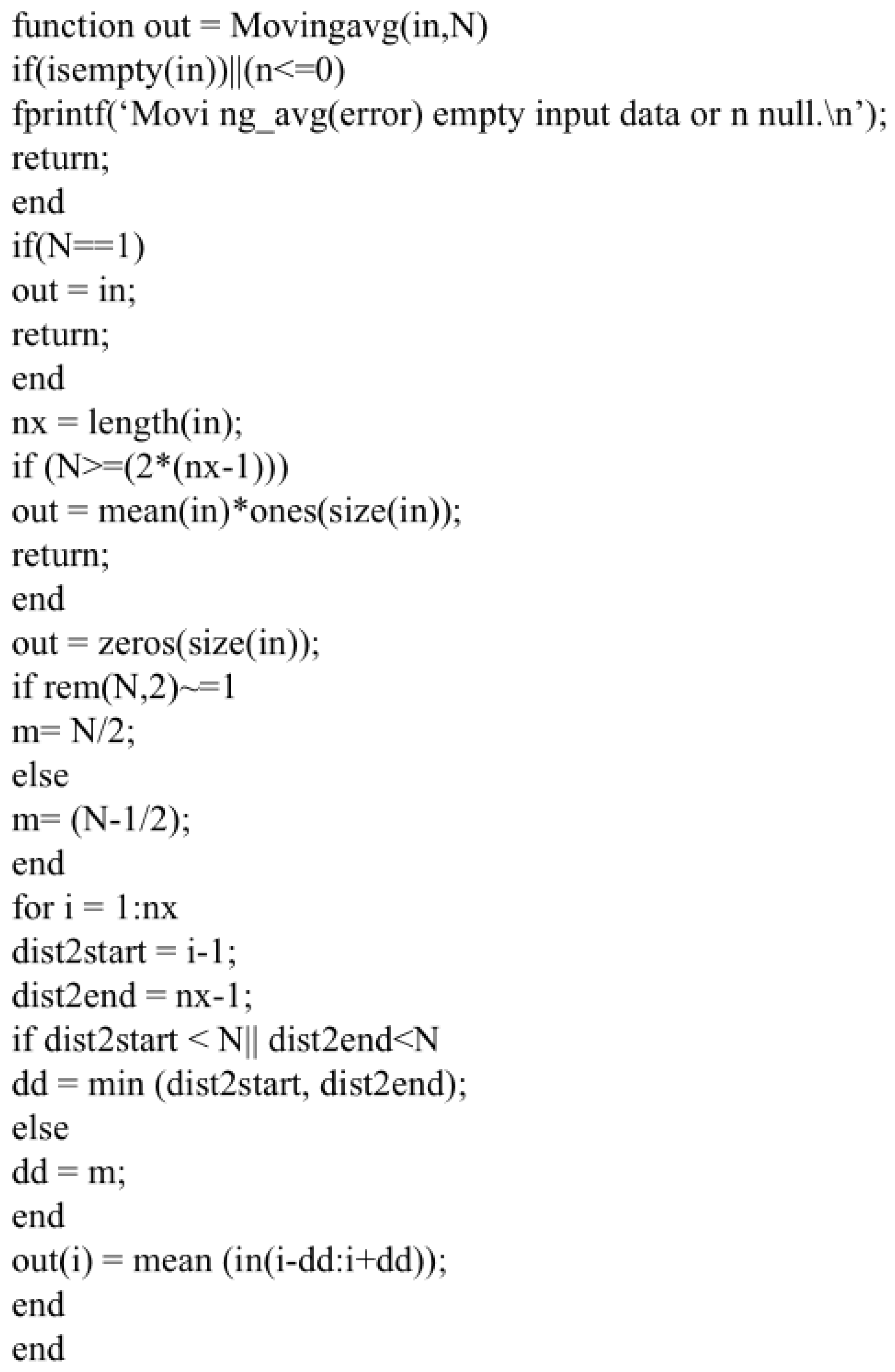

Matlab code for the function of moving average filter.

Figure 6.

Matlab code for the function of moving average filter.

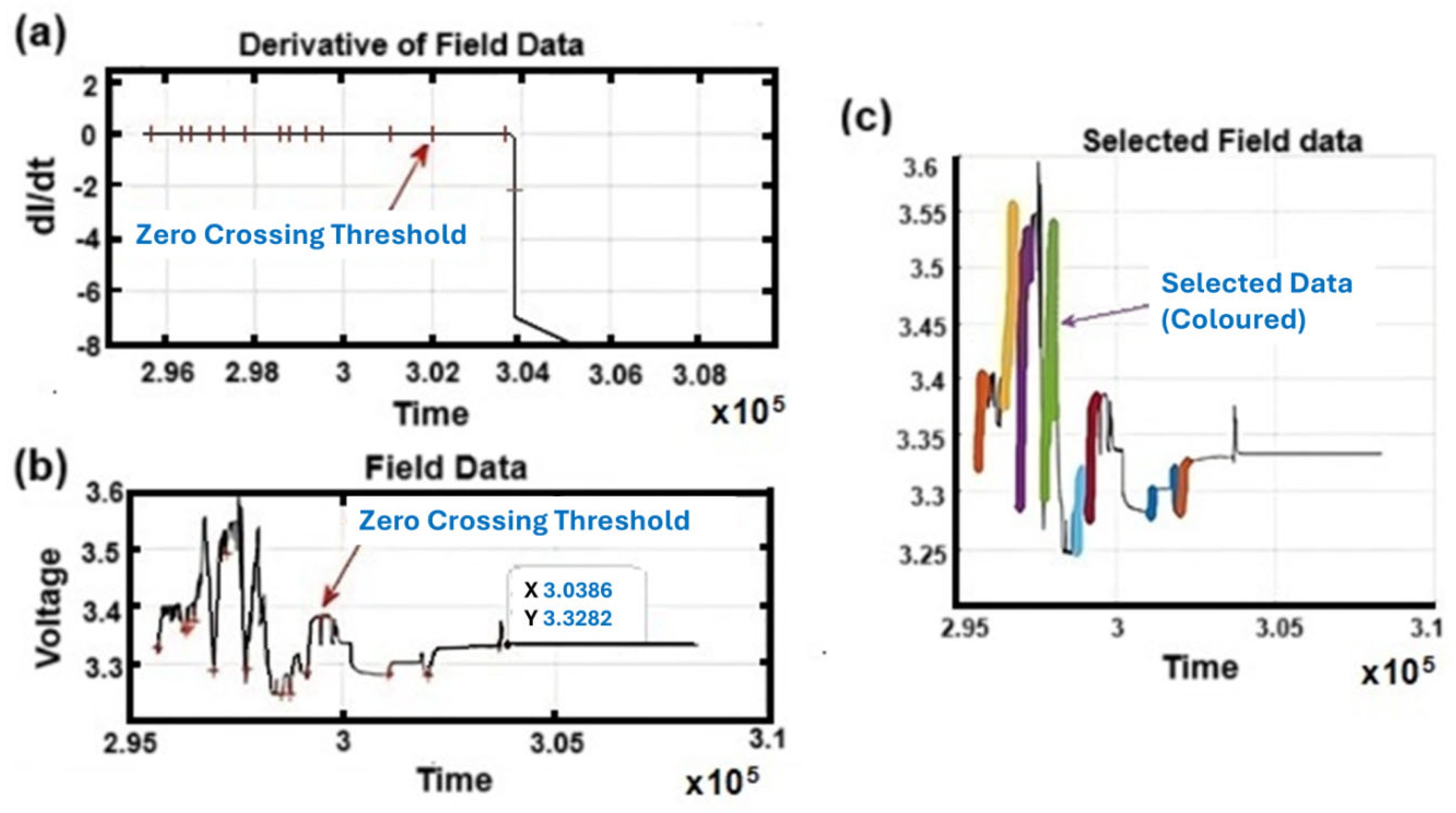

(a) shows the derivative of the current with respect to time, (b) represents the voltage field data as a function of time, with the red dots indicating the zero-crossing points, and (c) shows that the colored part is the selected field data.

Figure 7.

(a) shows the derivative of the current with respect to time, (b) represents the voltage field data as a function of time, with the red dots indicating the zero-crossing points, and (c) shows that the colored part is the selected field data.

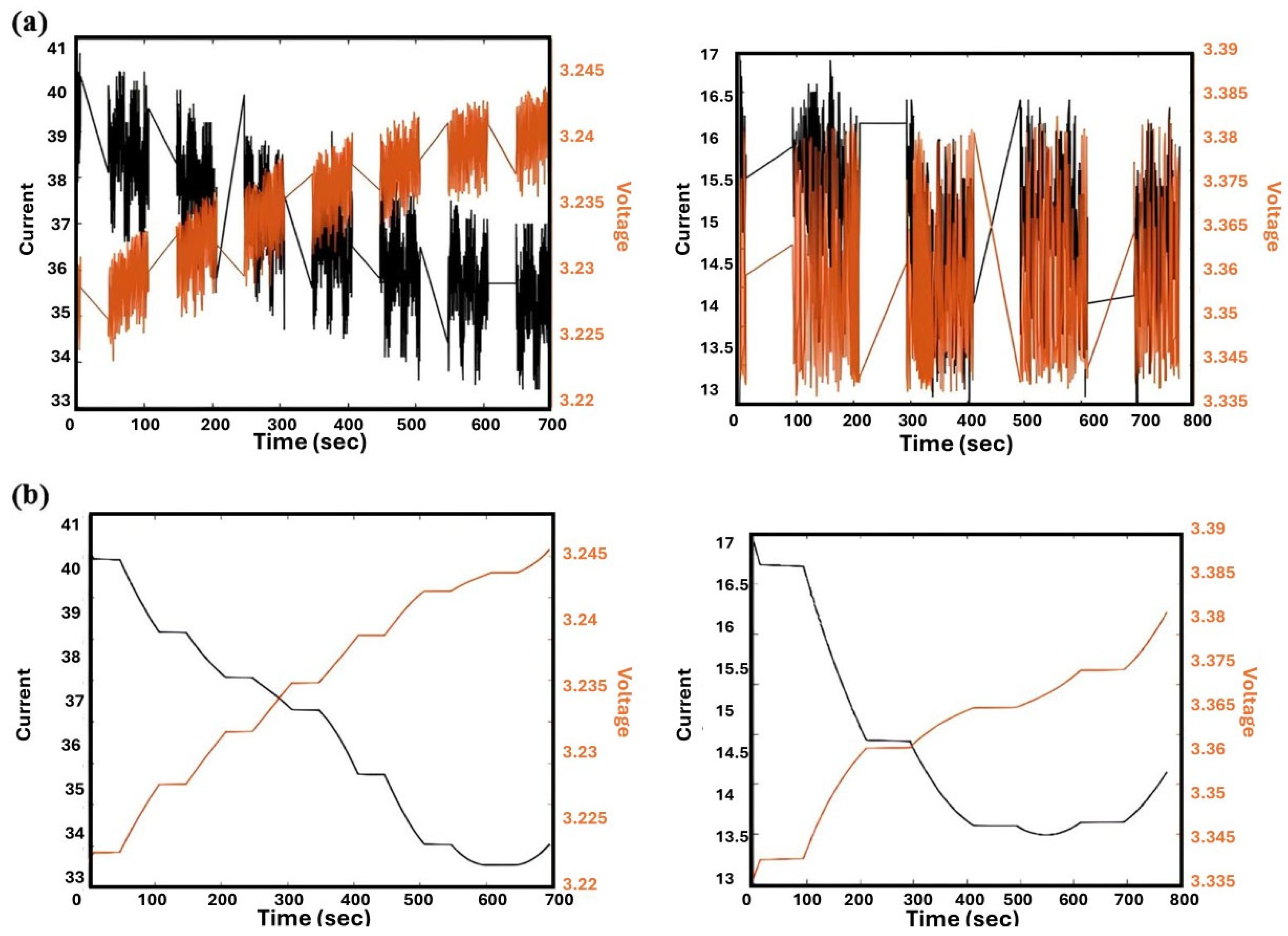

(a) Retrieved field data; (b) retrieved field data after filtering.

Figure 8.

(a) Retrieved field data; (b) retrieved field data after filtering.

Methodology for retrieving field data and estimating ECM parameters.

Figure 9.

Methodology for retrieving field data and estimating ECM parameters.

PSO flow chart.

Figure 10.

PSO flow chart.

Voltage with OCV impact.

Figure 11.

Voltage with OCV impact.

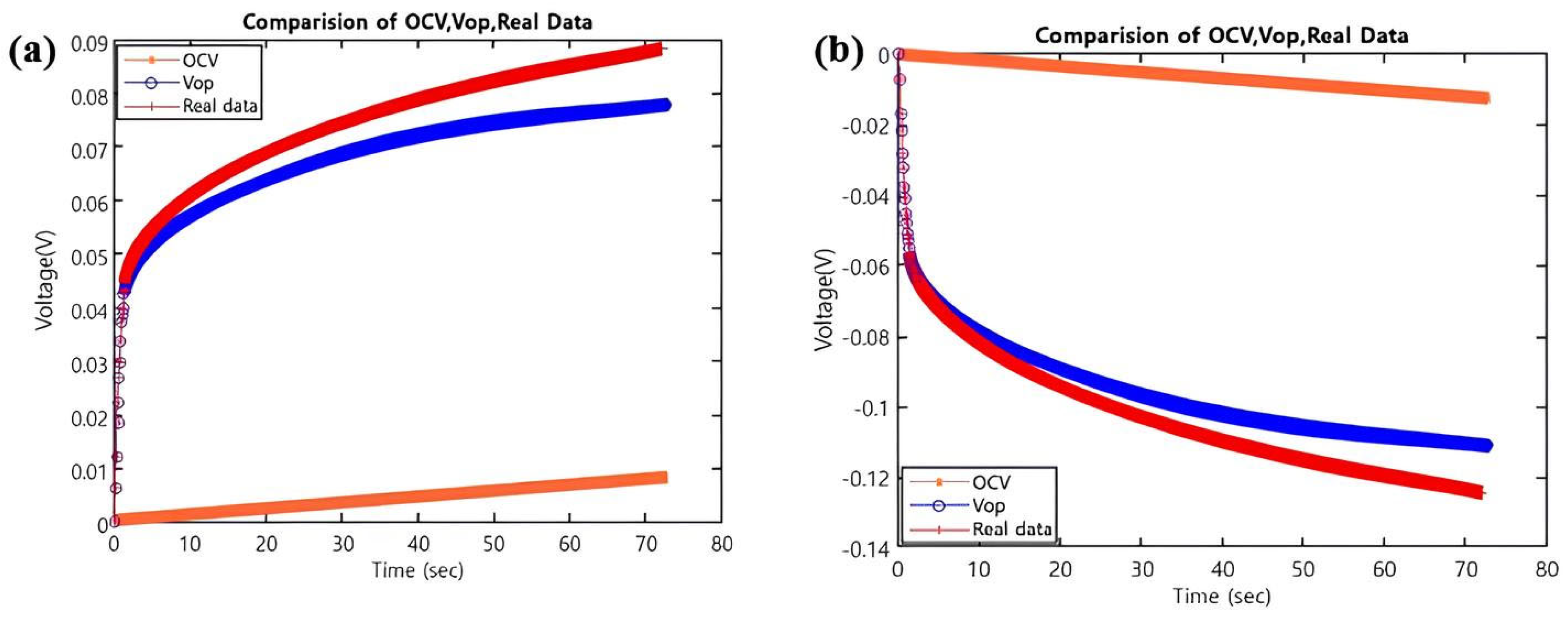

(a) Charge pulse; (b) discharge pulse.

Figure 12.

(a) Charge pulse; (b) discharge pulse.

(a) Comparison of real data and simulation data without OCV impact for charge pulse. (b) Comparison of real data and simulation data without OCV impact for discharge pulse.

Figure 13.

(a) Comparison of real data and simulation data without OCV impact for charge pulse. (b) Comparison of real data and simulation data without OCV impact for discharge pulse.

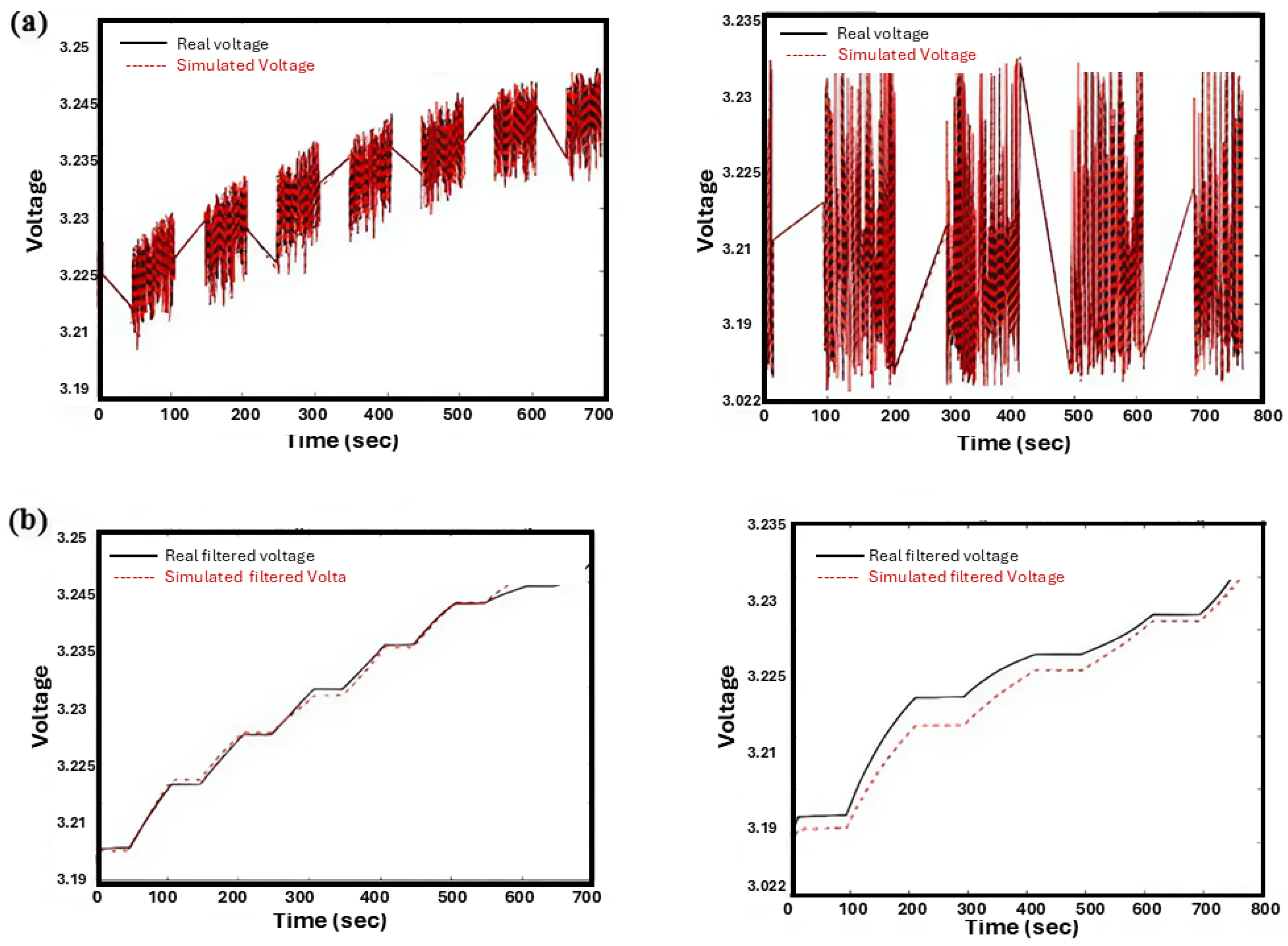

(a) Comparison of real voltage and terminal voltage. (b) Comparison of filtered real voltage and filtered terminal voltage.

Figure 14.

(a) Comparison of real voltage and terminal voltage. (b) Comparison of filtered real voltage and filtered terminal voltage.

Table 1.

Experimental procedure.

Table 1.

Experimental procedure.

| ID | Status | Time (hh:mm:ss:ms) | Cycle | Voltage (V) | Current (A) |

|---|---|---|---|---|---|

| 1 | CCCV_Chg | 4.200 | 1.05 | ||

| 2 | Rest | 00:10:00:00 | |||

| 3 | CCCV_DChg | 2.500 | 1.05 | ||

| 4 | Rest | 00:10:00:00 | |||

| 5 | Cycle | Begin ID: 1 | Times: 3 | ||

| 6 | CC_Chg | 00:12:00:00 | 4.200 | 1.05 | |

| 7 | Rest | 00:10:00:00 | |||

| 8 | Cycle | Begin ID: 6 | Times: 10 | ||

| 9 | CC_Dchg | 00:12:00:00 | 2.500 | 1.05 | |

| 10 | Rest | 00:10:00:00 | |||

| 11 | Cycle | Begin ID: 9 | Times: 10 |

Table 2.

Parameters for PSO algorithm.

Table 2.

Parameters for PSO algorithm.

| Parameters | Value |

|---|---|

| 0.690 | |

| 1.623 | |

| 1.623 | |

| No. of Particles | 50 |

| Maximum No. of Iteration | 250 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

Source link

Syed Adil Sardar www.mdpi.com