The shaft is an important accessory structure for the ventilation function in long and deeply buried traffic tunnels. Under the influence of various unfavorable factors, the stability of the shaft during construction excavation has become one of the challenges in tunnel construction [1,2]. With the development of transportation engineering and the wide distribution of karst, more tunnels need to be built in karst areas [3]. Karst, as an adverse geologic condition affecting the construction safety of underground facilities (e.g., tunnels, shafts), has been of great concern. Therefore, it is necessary to study the excavation stability of deep shafts in karst areas.

A series of studies have been conducted on the stability of shaft excavations. Cheng et al. [4] conducted a series of numerical simulations and proposed a stability control method for the surrounding rock during deep shaft excavation. Hou et al. [5] investigated the effects of high stress, inhomogeneous stratigraphy, and fault structures on the stability of deep shaft excavations and found that the range of the damage zones increased significantly when the wellbore passed through fracture zones or different lithologies. Walton et al. [6] used numerical simulations to understand the factors affecting the relative stability of the two shaft geometries, indicating that variations in shaft geometry are very effective in improving shaft stability. Tangjarusritaratorn et al. [7] performed a three-dimensional finite difference method analysis on the excavation process of deep shafts considering the three-dimensional arch effect and found that previous studies had underestimated the earth pressure acting on the shaft. Wang and Yang [8] carried out on-site monitoring of the construction process of the vertical shaft using the freezing method and analyzed the changing rules of freezing pressure, reinforcement stress, and concrete strain in the well wall. Their results showed that the accumulation of frost heave stresses exacerbated the stresses and deformations in the frozen soil walls, frozen tubes, and shaft walls during shaft excavation. Qiao et al. [9] monitored and analyzed the deformation characteristics of a 56.3 m deep circular shaft and found that excavation was the main factor causing the basement heave, which resulted in vertical movement of the shaft and the surrounding ground surface. Li et al. [2] investigated shaft lining damage incidents in the Huanghuai region of China, and the results showed that the main damage mode of the shaft lining is shear failure. Sun et al. [10] simulated the deformation and stress characteristics of the surrounding rock and shaft lining under the geological conditions of soft–hard rock strata based on the 3DEC program and found that stress concentration and bending moments are easily generated at the interface between soft and hard rock layers. Zhang et al. [11] used numerical simulation to investigate the influence of key rock mechanical parameters on the stability of the surrounding rock in deep shafts and proposed a method for estimating the stability of the surrounding rock. However, most of the current studies have not investigated the stability of excavation of deep shafts in karst areas.

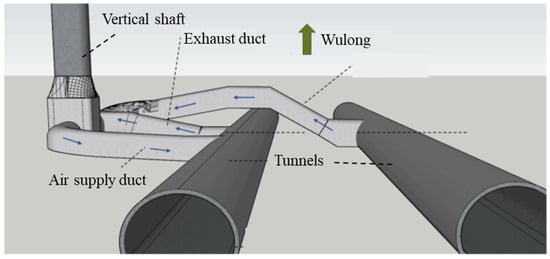

Zimuyan Tunnel is 7.4 km long and has been planned to be constructed with one ventilation shaft, which was opened by the raise boring machine (RBM) method. However, the RBM method excavates in the direction opposite to the direction of gravity of the rock mass, which is significantly different from the excavation method for general shafts and tunnels [12]. In this paper, ABAQUS finite element software (version 6.14) was employed to numerically simulate the excavation stability of the ventilation shaft of Zimuyan Tunnel in the karst area. By considering the existence of karst caves, an analysis was conducted on the displacement and stress fields of the surrounding rock during the construction stage using the RBM method. Furthermore, the deformation patterns were analyzed for different cave sizes and cave–shaft spacing, and the effect of the presence of the cave on the stability of the shaft excavation was evaluated. These findings provide technical references for the design and construction of deep and large vertical shafts in karst areas.

Source link

Guofeng Wang www.mdpi.com