1. Introduction

Cyclone separators are devices that utilize fluid pressure to generate rotational motion for two-phase and multi-phase separations when there is a difference in density [

1]. Due to their relatively low energy consumption, simple structure, recovery efficiency and other advantages, they are widely used in coal-fired, petrochemical, metallurgical and other industrial fields. Although cyclone separators have a simple structure, their separation and trapping processes involve extremely complex three-dimensional multiphase turbulent motion, thus increasing the difficulty of theoretical and experimental research [

2]. Nevertheless, studies on cyclone separators have continued to advance over the years. Bogodage et al. [

3] explored the capabilities of improved cyclone separators with down-comer tubes (solid loading rate = 0–8.0 g/m

3, inlet velocity = 10 m/s) and revealed that the separation efficiency of particles via down-comers increased when the separated spaces were enlarged and high-tangential-velocity-dominated zones were established. The study by Demir et al. [

4] suggested that the pressure drop declined with the enhancement of the body height and conical height, while it increased with the enhancement of the vortex finder height. Furthermore, a modified eddy current detector with a reflux cone and a helical gap was recognized as having good prospects in gas–solid separation in natural gas cleaning [

5].

Although much progress has been made regarding detection methods to measure the velocity distribution in the gas–liquid phase, such as in laser Doppler velocimetry (LDV) [

6] and particle image velocimetry (PIV) [

7], the development of experimental studies has been limited by the equipment’s high cost and low measurement efficiency. Currently, with the continuous advances of calculating software, computational fluid dynamics (CFD) is considered to be an effective method for the in-depth exploration and prediction of the flow fields of the separators. Moreover, the Euler–Euler [

7] and Euler–Lagrange equations are generally selected as the primary numerical approaches to analyze two-phase gas–solid flows. However, the Euler–Euler method only obtains the overall information of the flow field instead of tracking the position and velocity information [

8]. To overcome this drawback, the discrete particle method in the Lagrangian framework (CFD-DPM) has been introduced [

9]. The application of this method allows the flow behavior to be addressed from a particle perspective and more comprehensive results to be obtained by tracking the particles. Currently, CFD-DPM is widely used in investigating complex gas–solid turbulent flows in cyclone separators. Duan et al. [

10] found that by applying the Euler–Lagrange approach, the resistance time and distance of movement of fine particles in cyclone separators with inner cylinders were extended while eliminating upward and downward flow. Again, applying the Euler–Lagrange formula, Wasilewski et al. [

11] investigated cyclone separators with a specific inlet duct bending angle and found that the separation efficiency was limited by the angular margin. Afterwards, Safikhani et al. [

12] used the Rosin–Rammler distribution function to inspect the impact of various structural parameters on collection efficiency.

The above studies mainly explored the relationship between structural optimization and flow characteristics such as pressure drop and separation performance. However, it should be emphasized that wall erosion has become a primary problem restricting the application and development of cyclone separators, and few studies have addressed this issue. Specifically, the particles carried by fluids moving at high speeds within the cyclone are highly likely to cause wall erosion, in contrast to other dust removal equipment. Wall erosion directly restricts long-term operation, causing large economic losses to the product [

13]. Thiana et al. [

14] studied a cyclone separator with fluid catalytic cracking particles as the solid phase and found that erosion increased at velocities of 30 and 35 m/s and decreased with an increasing solid-loading rate. Ehsan et al. [

15] explored the effect of inhomogeneous surface roughness on cyclone erosion and found that the erosion rate of particles against inhomogeneous rough walls was less than that of smooth walls. Mohamadali et al. [

16] found that the gas flow rate and inlet temperature had the greatest effect on cyclone preheater erosion. Zhang et al. [

17] found that as the erosion thickness increases, the pressure drop decreases and the separation efficiency decreases. At the same time, with the increase in local erosion, the phenomenon of fine particles escaping is obvious and the stroke is overlapped, forming a high concentration of the ash ring and intensifying the wear. Zhao et al. [

18] proposed a draft plate inner member to improve the separation performance by suppressing the extrusion of the secondary flow with the inlet gas stream. It was found that as the angle of the plate increased, the pressure drop decreased and the separation efficiency decreased. A plate with an angle greater than 90° can substantially reduce the pressure loss, but the prerequisite for using this method is that the separation efficiency is not required to be high. However, the possibility of suppressing the effect of secondary return flow through the plate and thus influencing the internal flow field to regulate erosion is a question that deserves investigation.

Therefore, the study of the variation in the degree of erosion is essential to determine the optimum angle of the plate to improve cyclone operation [

19]. Meanwhile, CFD-based erosion calculation models are another powerful tool in addition to experiments to provide an in-depth understanding of complex turbulent flows and the calculation of wear.

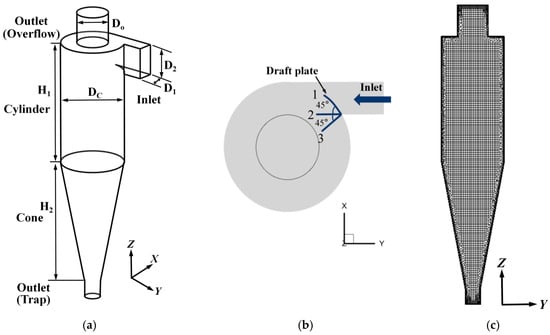

Based on the discussion above, this study focused on the effect of plates and their angles on the degree of erosion, flow field characteristics and particle behavior using the Eulerian–Lagrangian method. Firstly, the two-phase gas–solid flow pattern under the influence of the plate was presented, the distribution of the gas-phase velocity was investigated and the pressure drop was calculated. Secondly, particle trajectories were investigated in systems with and without draft plates and emphasis was placed on the effect of the plate on the degree of erosion on the walls. Finally, the interaction between the wall wear and the location of swirls and vortex nuclei in the flow field was further analyzed. This study aims to provide a comprehensive understanding of the complex interactions among the gas phase, particles and the body of the device with the addition of a plate.

5. Conclusions

In this study, the Euler–Lagrange method was employed to simulate the two-phase gas–solid flow in a cyclone separator with draft plates, and the effects of different draft plate angles on the flow characteristics (e.g., velocity, dynamic pressure and static pressure), particle behavior and the degree of erosion were discussed. The main results of this study were as follows.

- (1)

The presence of the draft plate significantly affected the movement of gas and particles. Increasing the angle of the draft plate effectively suppressed the compression of the inlet gas flow via the gyrating one-week gas flow, which reduced the pressure drop of conventional separators by 92%, improved the ability to rotate the pressure at static pressure and reduced energy consumption.

- (2)

Increasing the angle of the draft plate reduced the gas-phase flow field dynamics, leading to a reduction in the tangential velocity and effectively controlling the erosion phenomenon on the cyclone wall. Due to the larger swing of the spinning-in vortex nucleus at the bottom of the cone, the turbulence was more intense and the cone part of the cyclone separator was subjected to more serious erosion than the cylinder part.

- (3)

The existence of the plate improved the stability of the flow field while weakening the erosion of the cyclone wall. Due to the interactions of the wall, particles and the internal flow field, the local vortex area of the separator was minimized when the plate angle was 90°, which minimized the scope of influence on the internal secondary flow.

Current research has greatly reduced the energy loss and wall wear of cyclone separators, but there has been a lack of exploration of particle breakage and binding. Future research will be devoted to the study of individual particle behavior, which will be beneficial to the design and optimization of these systems.