1. Introduction

Throughout the years, research on the use of metallic alloys in biomedical implants has been of great relevance, since these must comply with a certain series of characteristics and very specific parameters to be considered optimal for biomedical use. Different requirements are needed to use materials for long term orthopedic implants [

1,

2,

3]. Among the most important are those related to the mechanical properties, which should have the most similar values possible to that of human bones. The main properties are low stiffness, high strength, and high hardness. In addition, those materials have to be biocompatible with the human body in order to avoid toxic components for the human body. In addition, those materials should demonstrate good corrosion behavior under biological fluids and, for materials used in bone joints, a wear resistance is required. In addition, it is highly recommended that materials pose a good antibacterial activity to avoid infections during the surgery process [

4]. Finally, it is expected that materials also show a good osseointegration; this is reached by controlling the pore features to mimic the bone structure [

5].

Currently, Ti alloys have had a great scientific development because they fulfill most of the medical requirements. These are widely used in different types of implants such as dental, external and craniofacial prostheses, and their use extends to surgical devices. The adaptation of Ti alloys for biomedical use is attributed to their high range of biocompatibility, which is the ability of a material to adapt to the human body without causing any adverse effects; this is in addition to generating an optimal cellular response so that the material in question is functional for the user. The Ti6Al4V alloy, composed of titanium (Ti), aluminum (Al) at 6% and vanadium (V) at 4%, meets the biocompatibility ranges necessary to be an applicable material for biomedical use based on the pH effects on it, as well as offering a unique combination of mechanical strength, light weight and excellent corrosion resistance [

6,

7].

Nevertheless, Ti6Al4V has the disadvantage of having very low antibacterial resistance, which directly affects its use as a biomedical material. It can lead to complications during and after the surgery due to bacterial infections which, directly compromises the useful life of the implant and the longevity of the human bone to which the implant is anchored [

8]. In addition to this, most of the Ti6Al4V alloy parts for biomedical implants are manufactured with the sintering process due to the complex morphologies used, which results in parts with porosity and low density, also affecting their mechanical properties in the long term [

9].

To overcome the issues associated with alloys, combinations with materials that have antibacterial activity, such as Ag, have been used [

10,

11,

12,

13]. It has been proven that TI6Al4V and Ag generate good antibacterial levels; M. Chen et al. [

14] made the addition of Ag in different wt.% and found a higher bactericidal rate in the samples with higher wt.% of Ag added. This resulted in a considerable improvement in the alloys based on these elements for biomedical use. Different research with Ag addition [

15] demonstrated a bactericidal rate around 99.99% for bacteria such as S. aureus and E. Coli, demonstrating that bacterial cell walls are completely altered by Ag.

Powder metallurgy is commonly used as a manufacturing process for biomedical prostheses because the powder sintering process has a lower production cost [

16]. However, since it has a porous part, there is a risk of failure due to the mechanical behavior of these structures [

17]. The addition of elements in metal matrix composites can be performed to reinforce them in different ways; an example is the assisted liquid infiltration which implies important improvements in the mechanical properties. Nevertheless, this technique has certain disadvantages such as the induction of microcracks which are detrimental to the composites [

18]. On the other hand, with pressureless liquid infiltration, a satisfactory infiltration by capillary phenomena can be performed, obtaining good results without these structural defects since no external force is required to infiltrate the reinforcement material into the composite [

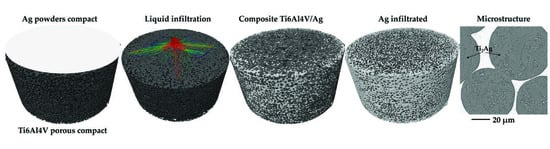

19].

The principle of the infiltration technique is to pass some material through a porous medium in order to fill the pores [

20]. Important aspects must be considered to have good infiltration levels such as wettability and permeability, in addition to inconsistencies derived from errors that may exist in the control of atmospheres and preparation of substrates that can lead to discrepancies in the contact angles. Sobczak et al. [

21] concluded that it is necessary to have a control or knowledge of the surface and the atmosphere used to avoid those problems. Infiltration can be used as a method of densification of a porous material completely changing its properties. Kumar et al. [

22] infiltrated a YBCO superconductor with Ag obtaining good levels of densification changing the pore volume fraction of the worked parts, in addition to their mechanical and microstructural properties. Arivazhagan et al. [

23] made Mg infiltration without pressure into a porous Ti6Al4V compact, completely improving the maximum compressive strength in the infiltrated parts. The mechanical strength was improved, going from 178 MPa of the porous structures to 415 MPa of the infiltrated compacts, thus improving their mechanical properties and densification. For the infiltration into a porous compact to take place optimally, it depends on different variables—one of the most important being the existing permeability. Olmos et al. [

24] carried out permeability studies in a Ti-6Al-4V porous compact through computerized microtomography, finding that the permeability is directly influenced by the pore volume fraction, the size of the channel, as well as the number and shape of the pores.

The Ti6Al4V/Ag combination, besides having good antibacterial properties, shows good results in terms of mechanical behavior. Solorio et al. [

25] performed sintering of Ti6Al4V powders with different vol.% of Ag, in order to perform compression tests on the sintered compacts, obtaining better results with higher vol.% of Ag added, due to the fact that they presented densification values around 97%. The results of the combination of these materials are beneficial since their mechanical and antibacterial attributes are improved, allowing the development of a composite material with a specific microstructure which allows its use in biomedical implants [

26]. The wettability of the Ag on the Ti or Ti alloys has not been studied from the wetting angle; nevertheless, it was reported that titanium is immiscible with different metals [

26] as Ag [

27]. In where a liquid Ag form during sintering enhanced the densification of composites. In both cases, the wettability of the alloy increased, which positively influenced the biological response of the implant.

As demonstrated, the Ti6Al4V/Ag combination is suitable for use in biomedical implants; however, it has a weakness in the density levels that it presents once sintered, which is a serious problem that compromises the life of a prosthesis. This can be solved with techniques such as gravity infiltration, thus being able to improve the mechanical properties without neglecting the antibacterial part. Since this option has not yet been studied, the selection of this technique allows it to be developed in its entirety. Therefore, the main objective of this work is to analyze the infiltration process from the point of view of the void space to be filled by liquid. Thus, porous compacts with different pore characteristics were prepared to evaluate the flow throughout the porosity with the aim of fabricating Ti6Al4V/Ag composites that could be used as bone implants. Additionally, a microstructural characterization and mechanical properties were evaluated in order to determine the viability for use them as orthopedic implants.