1. Introduction

Traditional food products hold a special place in the culinary heritage of nations, serving as a reflection of cultural history and regional identity. These time-honored dishes and ingredients continue to be cherished and enjoyed by people around the world. According to statistics, the market for traditional food products has been steadily growing, with global sales reaching an estimated USD 1.2 trillion in 2020. This growth can be attributed to a growing interest in culinary tourism, the increasing popularity of traditional and authentic flavors, and a desire for healthier, locally sourced options [

1]. In fact, a significant percentage of consumers actively seek out traditional or artisanal food products when shopping, citing a preference for quality, taste, and a connection to cultural roots. As the demand for traditional food products continues to rise, it underscores their enduring appeal and importance in preserving culinary traditions across the globe [

2].

India is the leading country, with diverse sweet products being produced traditionally. These sweet products include sandesh, kalakand, malpoa, srikhand, rasogolla, and gulab jamun, among others [

3]. These are prepared using various methods such as cooking, frying, roasting, grinding, and fermentation. Among various processes being adopted for such cases, deep fat frying is considered to be one of the simplest methods of cooking. It is a form of cooking that uses edible oil at temperatures beyond the boiling temperature of water. This temperature typically ranges from 120 to 210 °C, with 150–190 °C being the most prevalent range [

4]. The aim of the deep-frying process is to maintain flavor, a crunchy crust, and a moist cooked interior by sealing the meal in the heat of the oil. Malpoa is one of the popular deep-fried foods widely consumed across India [

5]. Additionally, it is eaten during high tea and as a brunch item.

During the deep fat frying process, water is removed, creating pores inside the food sample. On the other hand, oil is initially adsorbed on the surface of the food [

6]. Subsequently, it penetrates the pores, providing the desired food characteristics. The development of oil countercurrent flows and water vapor on the food’s surface fosters simultaneous transfer heat and mass [

7]. Other modifications of the food product during the frying process include the gelatinization of carbohydrates, denaturation of protein chains, and the disruption of middle lamellar cell adhesion [

8]. These variations are key for customer acceptance. On the other hand, the frying process causes physical and chemical changes in food that depend on the constitution of the food. Such changes include the development of the desired texture, flavor, and brown color. A percentage of the frying oil and polar compounds created by oil degradation are absorbed by food and contribute to the overall quality of the finished product. Furthermore, taste emerges, crispness is generated, and holes are formed [

9]. This results in the desired texture and sensory qualities.

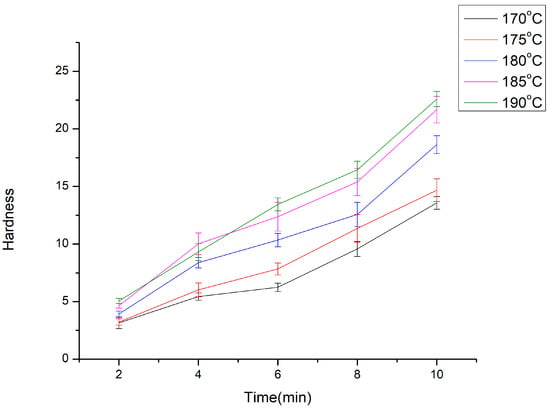

Among various modifications during the deep fat frying of malpoa, texture and color are important as desired characteristics of the fried product. The variables are greatly affected with the variation in frying temperature and time [

10]. On the other hand, frying temperature and time significantly affect caramelization and crust formation, which results in a definite effect on the texture and color of the product. Therefore, it is very necessary to investigate the variation in responses with frying temperature and time. Further, the kinetic study of the variation in color and texture would facilitate process–product optimization and the design of frying equipment. Mondal et al. (2017) examined the development and characterization of Chenna jhili balls using deep fat frying. The authors evaluated color and texture kinetics with a varied temperature and time from 120 to 140 °C and 3 to 20 min, respectively. The literature affirmed a variation in L

* of 46.53–26.76, in b

*/a

* of 3.944–0.4412, in ΔE of 32.460–52.668, in hardness of 0.822–2.452 N/mm

2, in stiffness of 1.214–5.750 N/mm

2, and in firmness of 2.875–9.126 N/mm [

11]. Similarly, Salehi (2018) investigated the variation in color with regard to the variation in the frying temperature of carrots during deep fat frying. The product was deep fat fried at a temperature of 130–190 °C and a frying time of 90–180 s. For such a case, the optimum values reported were redness (a

*) 22.30, yellowness (b

*) 48.44, and lightness (L

*) 55.74–49.21 [

12]. Hindra et al. (2006) investigated quality parameters of deep fat tofu in relation to the variation in frying temperature (147–172 °C) and time (5–35 min). Authors have studied the kinetics of color variation during this process. This investigation affirmed a variation in L

*, a

*, and b

* from 85.5 to 68.0, 1.17 to 6.72, and 18.8 to 34.5 [

13]. Further, the activation energy for the color variation was reported to be 76–165 kJ/mol.

On the other hand, the transfer of heat from the oil bath to the exterior of the produce occurs through convection, and then through conduction to the inner core. As the food reaches the boiling point of water, moisture evaporates and escapes, while fat from the surrounding oil infiltrates into the food. Therefore, frying can be characterized as a complex process of both heat and mass transfer [

14]. The available literature affirms few investigations for heat and mass transfer modeling of various food materials during deep fat frying. For chena jhili, heat and mass transfer coefficients reported were 69.80–103.18 W/m

2·K and 2.848–7.543 × 10

−5 m/s for 120–140 °C, respectively [

15]. Similarly, the corresponding values for deep fat fried gulab jamun were 94.10–122.34 W/m

2·K and 10.41–14.35 × 10

−5 m/s for 120–140 °C, respectively [

16]. On the other hand, heat conductivity and thermal diffusivity for the variation in frying temperature from 5 to 80 °C reported were 0.24–0.43 W/m

2·K and 7.6 × 10

−8–1.15 × 10

−7 m

2/s. The study of heat transfer in a plant-based fishball alternative revealed a thermal diffusivity of 7.56 × 10

−6 m

2/s [

17,

18].

A comprehensive study of existing state-of-the-art research confirmed limited studies on the characterization of deep-fried food products, including gulab jamun, tofu, sweet potatoes, and French fries. Most of the available literature focused on color and texture dynamics in the deep fat frying process. However, there are very few studies that have addressed heat and mass transfer modeling during deep fat frying and the textural parameters, including firmness, hardness, and stiffness. According to the available literature, deep fat fried malpoa has not been investigated for any characterization, including color, texture, heat, and mass transfer characterizations. Based on this, the objective of this study is to provide a detailed characterization of deep-fried malpoa that includes color and textural kinetics, as well as heat and mass transfer modeling during the deep fat frying process of malpoa. The ultimate goal of this work is to contribute to the identification of the optimal qualities of malpoa, which facilitates the process of designing products and processes, as well as the design and development of frying equipment for commercial usage.