1. Introduction

The objective of this paper is to solve the issues mentioned above by reviewing the state-of-the-art models of gas in a hydropneumatic accumulator in terms of how these models affect the error of a numerical simulation of the efficiency of energy recovery in a drive system. This review will result in practical recommendations on the model most suitable for simulation testing of drive systems with energy recovery. This study is limited to the mathematical models most commonly used to simulate drive systems, including models delivered by engineering software. The energy losses related to the resistance of hydraulic oil to flow are excluded from this study.

2. Energy Balance of a Hydraulic Accumulator

where U [J] is the internal energy of gas, Q [J] is heat, and W [J] is work.

where P [Pa] is gas pressure and V February is gas volume.

The most commonly used equation is Equation (3). When Equation (3) is used, the final energy balance formula does not involve the time derivative of pressure. On the other hand, the time derivative of volume is eliminated using Equation (4).

where cV [J∙kg−1∙K−1] is the specific heat capacity at a constant volume, mg [kg] is the mass of gas, T [K] is gas temperature, and t [s] is time.

where cP [J∙kg−1∙K−1] is the specific heat capacity at a constant pressure.

In this study, Equation (6) is selected for further simulation.

3. Models of Gas State Used in Modeling of Hydraulic Accumulators

- (a)

- Ideal gas law by Clapeyron (1834)

- (b)

- van der Waals real gas equation of state (1873)

- (c)

- Benedict–Webb–Rubin (BWR) real gas equation of state (1940) [13]

- (d)

- Redlich–Kwong–Soave (RKS) real gas equation of state (1972)

- (e)

In many studies identified by the author, the BWR and RKS real gas equations of state are claimed sufficient for typical engineering calculations. However, no specific numerical results or theoretical considerations have proved this recommendation or clarified its range of applicability.

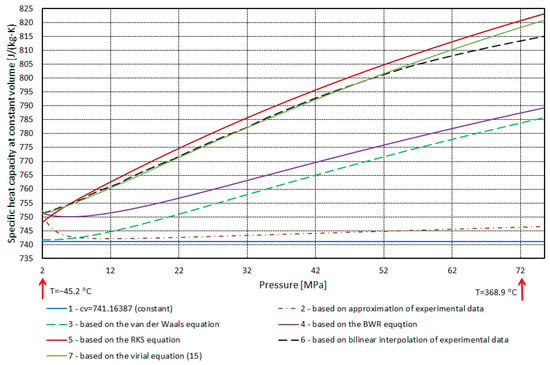

4. Specific Heat Capacity at a Constant Volume

The specific heat capacity is used in the energy balance equation for a hydraulic accumulator, where cp and cV denote the specific heat capacity at a constant pressure and constant volume, respectively. Both of these parameters are constant for ideal gas; however, in real gas, they depend on the temperature and pressure. In this paper, the energy balance equation is given by Equation (6), which only involves the specific heat capacity at a constant volume. Consequently, the methods for modeling the specific heat capacity at a constant volume are only analyzed below.

The approach referred to in (a) can be used when there are minor fluctuations in gas temperature and pressure in the hydraulic accumulator.

where cV,P=0 is the specific heat capacity at a constant volume and zero pressure.

When the cV predicted with Equation (16) and the 33-parameter virial gas equation of state is adopted as the reference, the following can be concluded:

Equation (16) gives the best predictions of cV when the RKS equation of gas state is substituted into Equation (16).

- Bilinear interpolation provides an even more accurate prediction of cv. The accuracy of this method strongly depends on the amount of experimental data available. For the pressure and temperature range considered herein, a large amount of experimental data is available (Figure 2). The tests carried out herein show that this method is fast and can be used successfully to update the estimate of cV while a computer simulation of hydraulic accumulator operation is running.

The changes in cV that occur during the operation of a hydraulic accumulator are relatively small. Therefore, the final result of a computer simulation of the hydraulic accumulator is unlikely to improve significantly due to changing the method to update the specific heat capacity during the simulation.

5. Modeling of Heat Transfer Between the Environment and the Gas in the Hydropneumatic Accumulator

where h [W/(m2·K)] is the overall heat transfer coefficient and Tw [K] is the temperature of accumulator walls.

where τ is the Thermal Time Constant and A is the surface of heat transfer between gas and accumulator walls.

where P0 [bar] is the initial gas pressure at a temperature of 20 °C.

CFRPs have many advantages over steel, including less weight and thermal expansion combined with superior rust resistance and flexural rigidity. However, CFRPs are significantly less resistant to heat; in practice, an operation temperature of less than 80 °C is advisable for CFRPs.

The material used to manufacture the housing of a hydropneumatic accumulator with a specified volume and pre-charge pressure will affect the Thermal Time Constant of the accumulator because of a significant difference in thermal conductivity of steel, aluminum, and CFRPs. The thermal conductivity of steel is 80 times greater than that manifested by CFRPs in the direction transverse to reinforcing inserts. This will result in the greatest Thermal Time Constants exhibited by the CFRP accumulators. The Thermal Time Constant will also be affected by the thermal insulation of the accumulator.

6. Models of Gas in Hydropneumatic Accumulators Used in Selected Commercial Software

A number of commercial software is available for the simulation of systems with hydropneumatic accumulators. In this paper, all of them could not be reviewed in detail. Therefore, the review presented herein presents the three most popular computation engines.

6.1. Matlab, Simulink, v. 2016b (Simscape Tool)

If a polytropic process is used in a simulation to describe the thermodynamic gas transformation, the simulation will capture the heat transfer between the gas and the environment to some extent. Unfortunately, if a constant polytropic index is specified for the entire simulation, the results of the simulation will only be relatively accurate for a specified gas pressure and for some constant rate of accumulator charging and discharging. This assumption is not acceptable for simulations of systems with energy recovery, as each individual cycle of operation of these systems may differ from the other cycles in terms of the rate at which the accumulator is being charged or discharged and the intervals between the consecutive operation stages when the accumulator is undercharging or discharging. The assumption that the polytropic process is the only gas transformation occurring in the accumulator and the polytropic index is constant over the entire simulation means the efficiency of energy recovery from the gas in the accumulator is 100%.

6.2. Simcenter Amesim, v. 2021.1

The heat transfer between the gas and the environment is defined using a single time constant that does not change during the entire simulation. The review of the state-of-the-art literature reveals that Simcenter Amesim is the software most used for the simulation testing of drive systems with energy recovery.

6.3. MSC Adams, v. 2005.0.0

The heat transfer between the gas and the environment is governed by a heat transfer coefficient hp·A [W/K], which is defined at the beginning of the simulation and does not change until the simulation ends. This coefficient can be calculated based on the Thermal Time Constant.

Unfortunately, the software was unstable when the model of the hydropneumatic accumulator was involved in the simulation. A very short integration step was used to successfully complete the simulation, resulting in a very long total simulation time. Furthermore, the most recent versions of MSC Adams no longer comprise the module for modeling hydropneumatic accumulators. In return, a co-simulation recommended that hydraulic systems be solved using, for example, EASY5 v. 2020 software.

7. Materials and Methods

7.1. Stage I—Prediction Errors Related to the Gas Equation of State and the Specific Heat Capacity Model

The objective of the first stage is to study the maximum errors caused using different gas equations of state to solve a specified engineering problem by numerical simulation. It has been assumed that these errors increase with an increase in the difference between the temperatures at which gas is compressed and expanded in the operation cycle of a hydropneumatic accumulator. Since the so-called reverse Otto cycle provides the greatest temperature difference possible, a hydraulic accumulator operating according to the reverse Otto cycle is analyzed herein.

where Vn is the reference volume of the accumulator; in this paper, the initial volume of gas V0 is adopted as the reference volume, and Vmin is the minimum gas volume during the operation cycle of the accumulator.

In the first stage of this study, the influence of the method to describe the gas in terms of specific heat capacity at a constant volume on the accuracy of the simulation has also been studied. The first of the investigated approaches was to calculate the specific heat capacity with Equation (16), involving the instantaneous gas temperature and pressure. In the second approach, the specific heat capacity was simply evaluated at some constant value, regardless of the gas state.

where i is the ID index of a given gas state equation, j is the ID index of a given value of accumulator pre-charge pressure, k is the ID index of a given value of the volumetric ratio, x is the number of considered individual values of accumulator pre-charge pressure, and z is the number of considered values of the volumetric ratio.

The measure given by Equation (25) is not sensitive to the increase in dispersion of the relative errors with an increase in both the pre-charge pressure Pl and the volumetric ratio Fmax. If a standard arithmetic mean were used, the average error would be mostly affected by the largest error, which is usually noted for the extreme values of Pl and Fmax. The measure defined by Equation (25) does not suffer from this problem. This approach is inspired by the methods developed in the field of operations research to solve a problem whose preferred solution must satisfy multiple contradictory quality factors.

7.2. Stage II—Prediction Errors Caused by Neglecting Heat Transfer

In real operation conditions of hydropneumatic accumulators, the differences between the temperatures at which the gas undergoes compression or expansion are far smaller than those assumed in the first stage of the research. This is related to the heat transfer between the gas and the environment that occurs while the gas is being compressed or expanded, as well as the time intervals between compressing and expanding the gas being so short that the gas temperature hardly reaches the ambient temperature. This stage of the research is executed to answer the following question: to what extent can the calculation errors revealed in the first stage be reduced by making the assumed thermodynamic cycle more realistic?

This operating cycle consists of four stages with duration times t1 through t4. During the cycle, the accumulator is charged and discharged at a constant rate (Q1 = const., Q2 = 0, Q3 = const., Q4 = 0). The parameter Fmax is the same for each consecutive cycle. Since duration times t1 through t4 significantly affect the temperature of the gas in the accumulator, different values for the duration times were assumed during the tests. However, such duration times were chosen for simulation so that they corresponded well with duration times noted for real systems with energy recovery.

In this research stage, the models are only compared with each other in terms of the accuracy in predicting the efficiency of recovering the energy supplied to the accumulator. The calculations correspond with a 10 L accumulator with steel housing. Furthermore, since accumulators are also made from materials that translate into a greater Thermal Time Constant, this research stage includes computations related to a hypothetical accumulator whose Thermal Time Constant is three times greater than that of the steel accumulator.

7.3. Stage III—Prediction Errors of the Hydropneumatic Accumulator Models Delivered by Commercial Engineering Software

8. Results

The lower section of each of the tables presents the reference value of the analyzed quantity calculated with the reference model and marked with the symbol F. In the columns on the left, and in the upper section of the table, conditions captured by the simulation are specified, including the accumulator pre-charge pressure and the parameter Fmax. The main part of the table presents the absolute errors exhibited by the tested gas models when predicting the analyzed quantity. The absolute error typical for a specified gas model is calculated as the prediction made with that model minus the value brought by the reference model. The prediction quality of each model is also rated in the diagram; the lower the rating, the better the prediction quality.

Based on the results obtained, the following conclusions can be drawn:

The greatest error has been noted for the model based on Clapeyron’s equation, which meets initial expectations. This model is expected to show an increase in prediction error with an increase in gas pressure, as well as when the gas approaches the phase transition curve because theoretical derivations leading to this model neglect a finite volume of gas particles, the possible attraction and repulsion of gas particles, and the possible formation of a new phase in the gas.

The computation errors caused by the model based on Clapeyron’s equation are so large that this model cannot be used to predict the behavior of gas under conditions similar to those assumed in this study. The efficiency in recovering energy from a conventional accumulator predicted with this model suffers from an error of approx. 10%.

The van der Waals equation reveals satisfactory accuracies for the pressures and temperatures meeting typical operation conditions of real hydropneumatic accumulators. At extremely high pressures, this equation leads to unacceptable errors. This simple equation is a quick remedy to find the initial conditions of a simulation and carry out the simulation.

- The behavior of the gas has been captured the best by the BWR equation. Because of the relatively large number of coefficients involved in this equation, it can successfully describe the behavior of the gas over a relatively large range of temperatures and pressures (see Figure 11 and Figure 12). Unfortunately, this equation cannot provide an accurate prediction for the instantaneous specific heat at constant volume (see Figure 1). Probably, for this reason, the BWR equation is not the best option, which has been revealed in the rankings posted under the tables with the test results. Therefore, in simulations based on the BWR equation, the instantaneous specific heat capacity should be predicted with a method different from the approach adopted in this article.

- The RKS equation with the Ghanbari–Check amendment, labeled EV herein, exhibited a performance almost as effective as the BWR equation. According to Figure 11 and Figure 12, the RKS equation is less accurate in modeling gas behavior; however, it gives more reliable predictions of the instantaneous specific heat at a constant volume.

The models featuring the dynamic update of the specific heat at a constant volume have generally produced better results, except for a few exceptions. For example, the BC model delivers the best prediction for pressures P1; however, this has been achieved at the expense of inaccurate estimates of temperature T1.

- A comparison of the results plotted in Figure 11 and Figure 12 leads to a conclusion that for some models, the error related to the gas equation of state can be either a positive or negative value, depending on the gas temperature. Furthermore, the temperature can affect the rate at which the error caused by an increase in pressure grows.

The results confirm the general statement quoted in the literature that all of the analyzed real gas equations of state provide satisfactory accuracy in predicting the nitrogen pressure and temperature when the typical operating conditions of hydropneumatic accumulators are considered using these equations.

The computations carried out in the first stage prove that all of the tested real gas equations are suitable for simulation studies. Thus, they do not need to be investigated in the second stage. The only issue that needs to be tested is to find out whether the ideal gas law could also be successfully applied for simulation under certain conditions.

The following conclusions can be drawn from the second stage of this study:

- The model based on the ideal gas law gives accurate results if duration times t1 through t4 are short and Fmax is small. It should be noted that in a number of studies, including [28], Fmax is estimated at approx. 40%.

- In many real applications of hydropneumatic accumulators, each of the duration times ti is from 6 s to 12 s [2]. If these are investigated with the model based on the ideal gas law, and Fmax = 60% is assumed, the energy recovery efficiency is overestimated by approx. 6% (for the steel body accumulator).

When duration times ti exceed 60 s, the overestimation may be even larger; it may be as large as the errors obtained in the first stage.

The higher the efficiency in recovering the energy from the real hydropneumatic accumulator, the more accurate the predictions of the efficiency delivered by the model based on the ideal gas law. This is because the higher the efficiency of the real process, the smaller the difference between the pressures recorded at any specified gas volume during gas compression and expansion. When the pressures during the real process are similar, their model predictions will suffer from almost identical error magnitudes. If the errors are identical, they will cancel out each other when the efficiency of energy recovery is calculated.

Thermal Time Constant and the time the operation cycle of an accumulator lasts are decisive for the efficiency of the accumulator. The efficiency will increase by increasing the Thermal Time Constant and decreasing the operation cycle duration.

- The results in Figure 13 are related to a conventional design accumulator with steel housing, while Figure 14 refers to an accumulator whose Thermal Time Constant is 3 times greater than that of the conventional design steel accumulator. The increase in the Thermal Time Constant causes both the efficiency predictions and the errors in predicting the efficiency to change slower as duration times t2 and t4 increase.

When duration times t1 through t4 do not exceed 5 s, and an accumulator with an increased Thermal Time Constant is considered, the errors in predicting the efficiency of the accumulator in recovering energy do not significantly exceed 1%. Under these conditions, the model based on the ideal gas law proves acceptable accuracy.

During the tests with MSC Adams v. 2005.0.0 software, the hydropneumatic accumulator was charged with a slightly greater amount of hydraulic oil (Fmax = 60.06). Consequently, the prediction for pressure P2 resulting from this simulation slightly exceeded its respective prediction derived from the author’s model.

9. Summary

This paper presents a discussion on the effect of the gas state equation on the accuracy of the numerical model of a hydropneumatic accumulator. The ideal gas law by Clapeyron, and the equations of van der Waals, BWR, and RKS, including the genuine RKS equation and the Ghanbari–Check amendment, have been evaluated in terms of the accuracy in predicting the efficiency of energy recovery from the gas in a hydropneumatic accumulator. A model based on the so-called virial gas equation of state has been used as a reference model. The evaluation has been carried out using two models of heat transfer between the environment and the gas in the accumulator; according to the first model, the heat transfer is governed by the so-called reverse Otto cycle, while the second one is governed by the Thermal Time Constant.

The results obtained herein show that in the typical operating conditions of hydropneumatic accumulators, all of the investigated real gas models can predict the efficiency of energy recovery from the gas in the accumulator with an error not exceeding ±1%, which is satisfactory in the author’s opinion. According to this study, in extreme operating conditions, which are unlikely for real accumulators, the prediction error manifests an increase.

The analyses presented herein clearly prove that the results of simulation computations of a hydropneumatic accumulator are likely to suffer from unacceptable errors when the simulation model of the accumulator is derived from the ideal gas law by Clapeyron. However, this refers only to the hydrostatic drive systems with energy recovery that include a conventional accumulator design and exhibit relatively long periods when the accumulator is undercharging or discharging, long intervals between these periods, and/or irregular and varying cycles of the accumulator operation. Unfortunately, the conditions mentioned above are typical for hydrostatic drive systems with energy recovery, including lifting systems of forklifts, manipulators of earthmoving machinery, and drive systems of mobile machines.

Even greater prediction errors may occur when a polytropic process and a constant polytropic index are assumed to simulate the thermodynamic process that occurs to the gas in a hydropneumatic accumulator. Unfortunately, these are assumed by most of the models of hydropneumatic accumulators predefined in commercially available software for the simulation testing of hydrostatic drive systems. Few exceptions comprise MSC Adams v. 2005.0.0 and various versions of Simcenter Amesim software.

It is expected that this paper will let the readers understand the process of modeling gas in hydropneumatic accumulators. Furthermore, this paper provides a number of guidelines, supported by the results of numerical calculations, on how to select a gas model reasonably suited for simulation testing of a specific drive system with a hydropneumatic accumulator.

Source link

Andrzej Kosiara www.mdpi.com