1. Introduction

In recent years, permanent magnet-assisted synchronous reluctance motors (PMA-SynRMs) have become one of the hot research topics in the field of electric motors, and the related research results have been reflected in many studies [

1,

2,

3,

4,

5]. PMA-SynRMs cleverly combine the advantages of permanent magnet synchronous motors (PMSMs) and synchronous reluctance motors, and have the characteristics of strong output torque, high power density, excellent efficiency, excellent speed regulation, and low cost [

6,

7]. The rotor is designed with a multilayer flux barrier topology, which effectively increases the motor’s pole ratio and thus fully utilizes the motor’s reluctance torque [

8,

9,

10,

11,

12]. By reducing the amount of rare-earth permanent magnets used, the PMA-SynRM is able to achieve power density and efficiency levels similar to those of PMSMs. In addition, the PMA-SynRM is superior to the PMSM in terms of speed regulation [

13,

14]. Due to its affordable price and excellent performance, the PMA-SynRM has shown promising applications in many variable-speed drives such as water pump compressors, household appliances, electric vehicles, and medical devices [

3,

15,

16,

17,

18,

19,

20,

21]. However, since the permanent magnets of PMA-SynRM are mostly composed of multi-layer thin permanent magnets, they are exposed to a high risk of demagnetization. Therefore, how to further enhance the stability and reliability of PMA-SynRM has become an important direction for many scholars to study.

Currently, the studies on anti-demagnetization performance of PMA-SynRM mainly focus on the design of the flux barrier structure, permanent magnets, and magnetic circuits. One study [

22] investigated the flux density distribution at each position/layer on the permanent magnet. The risk of demagnetization was also assessed by obtaining the working point of the permanent magnet based on the variation of the excitation current, current phase angle, and temperature. The results of the analysis showed that a high current phase angle coupled with the effect of high temperature was the main cause of demagnetization of the permanent magnet. Another study [

23] mentioned that the width and thickness of the permanent magnet should be increased to reduce the risk of demagnetization in PMA-SynRMs. An analytical method is also proposed, where the width and thickness of the permanent magnets could be calculated based on the given air-gap flux density and the stress of the permanent magnets themselves. Such an approach improved the anti-demagnetization performance of the PMA-SynRM, but also increased the cost of the permanent magnet. One study [

24] comparatively analyzed the demagnetization under different number of layers of flux barrier, permanent magnet combinations, and number of poles. The results showed that the two-layer flux barrier and the eight-pole design had lower risk of demagnetization. In another study [

25], it was shown that under continuous loading and demagnetization conditions, small and medium sized machines were more resistant to demagnetization compared to large machines and had scope for transient overloads. A subsequent study [

26] pointed out that by introducing the bypass magnetic bridges at the end of the flux barriers, it was possible to allow part of the armature magnetic field to pass through the bypass magnetic bridges, reducing the demagnetization effect on the permanent magnets. Simulation results showed that this bypass magnetic bridge structure significantly improved the anti-demagnetization performance of the motor. A study [

27] compared the anti-demagnetization performance of ferrite assisted synchronous reluctance motors with centralized and distributed windings and found that the distributed windings were able to provide stronger anti-demagnetization performance. In addition, the authors found that optimizing the shape of the end of the flux barrier from square to triangular also significantly enhanced the anti-demagnetization capability of the motor. The authors of [

28] also used the optimization of the shape of the end of the flux barrier and thickening of the ferrite permanent magnets in the demagnetization-prone region, which resulted in a remarkable improvement in the anti-demagnetization performance of the motor. However, this optimization method increased the magnetic leakage of the motor and reduced the convexity of the motor, thus affecting the electromagnetic characteristics of the motor. In this paper, the anti-demagnetization performance of PMA-SynRM with asymmetric-rotor is optimized without increasing the cost of permanent magnets. The width and height of the bypass magnetic bridge, as well as the angle of the flux barrier and the drop height of the permanent magnet, are found to be more sensitive to the demagnetization of the permanent magnet through FEM simulations. These two characteristics are used to optimize the rotor structure of the proposed model to ensure its torque performance while minimizing the risk of demagnetization. After multi-objective optimization, the anti-demagnetization performance of the PMA-SynRM with an asymmetric-rotor is significantly improved with no loss in torque performance. The torque ripple is also reduced.

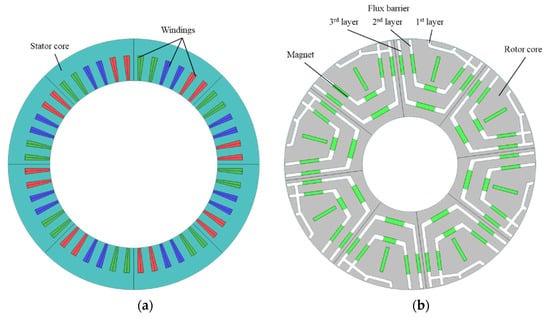

In this paper, the problem of poor anti-demagnetization performance of the asymmetric-rotor PMA-SynRM is optimized. Based on the above study, this paper analyzes the effects of the rib flux barrier bypass magnetic bridge and permanent magnet position on demagnetization. The topology of the rotor is optimized to reduce the risk of demagnetization. The sections of the article are organized as follows: In

Section 2, the stator-rotor topology of the basic model is presented and a simplified analytical model is developed. The basic model is also analyzed by demagnetization simulation. In

Section 3, the single-pole rotor topology and parameters of the proposed model are given. The effects of rib bypass magnetic bridge width

d and height

h as well as flux barrier angle

C3 and permanent magnet drop height

H on permanent magnet demagnetization are also investigated. In

Section 4, optimal design, sensitivity analysis, and multi-objective optimization are carried out. In

Section 5, no-load analysis, load analysis, and anti-demagnetization performance analysis are carried out for both basic and optimized models. In

Section 6, a short conclusion is provided.

6. Conclusions

In this paper, the poor anti-demagnetization performance of PMA-SynRM with asymmetric-rotor is investigated and optimized without changing the structure and usage of permanent magnets. Demagnetization simulations are carried out for the basic model at a temperature of 200 °C and 8 times the rated current. The results show that severe irreversible demagnetization of the permanent magnets in the second and third ribs of the flux barrier occurs, with maximum demagnetization rates of 82.69% and 24.46%, respectively. It is found that adding bypass bridges and changing the position of permanent magnets in the second and third layers of the flux barrier ribs of the basic model could effectively improve its anti-demagnetization performance. The maximum demagnetization rate of the permanent magnets is found to decrease significantly with the increase of the rib bypass magnetic bridge width d and height h, as well as the flux barrier angle C3 and the drop height H of the permanent magnets, as analyzed by the demagnetization simulation. This allows the proposed model to have better anti-demagnetization performance without affecting its torque performance too much. In this paper, the sensitivity analysis and multi-objective optimization of the rotor flux barrier structure of the proposed model are carried out. After optimization, the no-load flux density, no-load Back-EMF, and average torque of the optimized model are basically the same as that of the basic model. The torque ripple of the optimized model is reduced by 44.14% compared with the basic model, and the maximum demagnetization rate of the permanent magnets are reduced by 81.44%. The anti-demagnetization performance of the optimized model is significantly improved, and it has better stability and reliability.