3.1. Structural Investigation of Star-Shaped PLA Polymers

Star polymers present lower T

m as well as T

g, and crystallization temperatures (T

c) than their linear equivalents. Furthermore, star-shaped PLA copolyesters exhibit coiling, and have lower hydrodynamic volumes and higher viscosity than linear PLA. Numerous studies on PLA star polymers have investigated their potential use in drug delivery and self-assembled micelles [

49,

50,

51,

52]. Researchers have examined their morphology, solution behavior, and loading capacity. Small molecules and model drugs have been successfully encapsulated, with release profiles typically showing reduced burst effects and shorter initiation times compared to similar linear systems. Star-shaped architectures provide enhanced control over degradation rates, presenting significant potential for fine-tuning these systems for controlled release in biomedical applications [

50].

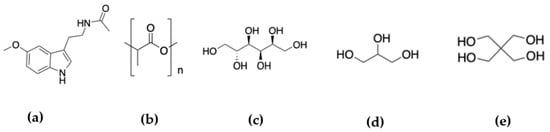

The structural characteristics of the synthesized copolyesters were investigated using

1H NMR spectroscopy. The spectrum, shown in

Figure 2, displays all the expected resonance signals corresponding to PLA. Specifically, a doublet at 1.58 ppm is attributed to the methyl group (-CH

3), while a quartet at 5.16 ppm corresponds to the methine group (-CH). Additionally, a peak at 5.02 ppm indicates the presence of residual unreacted lactide. For the PLA-polyol samples, a resonance signal at 4.36 ppm is observed, which arises from the hydroxyl groups (-OH) adjacent to the terminal chain-end, CHOH. These findings are in alignment with those previously reported, confirming the successful ring-opening polymerization (ROP) of lactide into PLA [

53]. The presence of the characteristic signals for both the main polymer backbone and residual lactide underscores the efficient polymerization process. For copolyesters incorporating polyols such as glycerol, sorbitol, and pentaerythritol, the proton signals from the polyols are not prominently visible in the corresponding spectra. This is likely due to the low concentration of polyols used during polymerization (0.5%

w/

v).

In combination with

1H NMR, ATR-FTIR spectroscopy was also utilized to further confirm the structure of the synthesized polymers (

Figure 3). In the PLA spectrum, several characteristic peaks were identified: a double peak at the region of 2900 cm

−1, corresponding to the stretching vibrations of the C-H bond (assymetric, symmetric); a strong peak at 1753 cm

−1, attributed to the carbonyl group (C=O); a peak at 1452 cm

−1, associated with the methyl hydrogens (-CH

3); the peaks at 1180 cm

−1 and 1082 cm

−1, arising from the stretching vibrations of the C-O-C bond. Similarly, the spectra of the PLA copolymers exhibited the same characteristic peaks, indicating that the core structural features of PLA were retained in all samples. Again, the very low concentrations of the polyols incorporated into the copolymers (e.g., glycerol, sorbitol, and pentaerythritol) did not significantly alter the spectral features. Their presence led to a slight broadening of the aforementioned peaks, without introducing new or shifting existing peaks.

3.6. Dissolution Test Results and Korsmeyer–Peppas Release Kinetics

Figure 6 demonstrates the in vitro % release of MLT from the formulations F1–F16 and the commercially available drug Circadin

® vs. time.

Table 3 presents the similarity factor (f

2) analysis results for % release, comparing all formulations with the commercial product Circadin

®. Dissolution profiles are considered similar when 50 ≤ f

2 < 100, with F1, F6, F9, F11, F12, F13, and F14 meeting this criterion.

The Korsmeyer–Peppas equation fitting results, are shown in

Table 4. The release data showed a good fit with the Korsmeyer–Peppas equation

R2 values ranging between 0.85 and 0.98.

The dissolution profile of MLT from the F1 and F3 formulations (

Figure 6a), at pH 4.5, is similar. F1, containing the polymeric excipient neat PLA, and F3, comprised of the polymeric material PLA-glycerol, show at t = 2 h, ca. 43.6% MLT release, almost identical to the commercially available drug, Circadin

®. This release profile similarity trend, between F1 and F3, is continued and at t ≥ 2 h, reaching quantitative release at t = 7 h. This modified MLT release from the F1 and F3 formulations could find application in patients facing sleep onset and mainly sleep maintenance problems. From the F2 (PLA-sorbitol) and F4 (PLA-pentaerythritol) formulations, MLT is released, at t = 2 h, at 81.3% and 62.4%, respectively. The much higher release of MLT from the F2 formulation mirrors the influence on the MLT release due to the presence of six hydroxy-groups in the PLA-sorbitol derivative, instead of the four hydroxyls in the PLA-pentaerythritol F4 formulation. The higher the number of OHs, the higher is the MLT release from the formulations, due to enhanced hydrogen bond formation mainly between the C5-OMe H-bond acceptor moiety in melatonin and the H-bond donor OH groups in the PLA-sorbitol derivative; this leads to a more favourable aqueous dissolution of MLT from the F2 formulation. It is known, that the higher the number of hydroxyl groups in excipients, the better are the solubility and dissolution rates of the APIs via hydrogen bonding interactions (

Figure 7), [

57,

58]. Thus, in view of this, formulations F2 and F4, and especially F2, could provide satisfactory treatment for patients with sleep onset problems.

According to the obtained data, in terms of the MLT release kinetics, the formulations F1, F3, and F4 exhibited a non-Fickian or anomalous diffusion mechanism (0.45 < n < 0.89), indicating a combination of simple diffusion and polymer relaxation (Case II diffusional transport). This behavior suggests that the release of MLT is influenced by both drug diffusion through the matrix and the polymer’s swelling or relaxation process, which is characteristic of non-Fickian transport [

59]. The presence of the excipients reported herein in these developed formulations may lead to more complex interactions between drug molecules and the polymer matrix, contributing to anomalous diffusion. In contrast, formulation F2 follows a Super Case II release mechanism (n > 0.89), which is commonly associated with systems where polymer relaxation dominates. The release rate is primarily controlled by the polymer matrix, which swells significantly and leads to a constant release rate, a mechanism previously described in systems with highly swelling polymers [

59].

In

Figure 6b the % MLT release vs. time from the F1, F5, and F9 formulations and Circadin

® is depicted. These formulations are comprised of the same polymeric material, neat PLA, the latter two, however, containing half the quantity of neat PLA (33 mg), compared to F1 (67 mg). F5 shows the highest MLT % release (49.79%), at t = 2 h, and 100% release, at t = 5 h, faster than from F1, F9, and Circadin

®. Notably, the lowest % release of MLT (36.3%), at t = 2 h, is shown from F9. The low % release from F9 is possibly due to the 6-fold higher quantity of MCC (119 mg) in this formulation compared to the 20 mg MCC present in F1 and F5. This leads to increased gel formation in the case of F9, when MCC comes in contact with the aqueous medium, resulting in MLT release retardation [

60,

61].

According to MLT release kinetics obtained via the Korsmeyer–Peppas equation (

Table 3), it is concluded that, in the case of the F1, F5, and F9 formulations, a non-Fickian/anomalous diffusion release mechanism (0.45 < n < 0.89) is followed, i.e., a combination of simple diffusion and Case II transport of abnormal diffusion.

Figure 6c illustrates the % MLT release vs. time from F2, F6, F10, and Circadin

®. These formulations are comprised of the same polymeric material, PLA-sorbitol, differing, however, in the relative amounts of this excipient, and in the relative amounts of the other formulants they are comprised of. Formulation F2 shows the highest MLT % release (81.3%), at t = 2 h, followed by a rapid release of 100%, achieved at t = 4 h, which is much faster than that from Circadin

® and the formulations F6 and F10. The lowest % release of MLT, at t = 2 h (44.9%) and until 100% release is achieved at t = 8 h, is shown in the case of F6, where the quantity of the gel forming HPMC is relatively high, and that of the aqueous dissolution enhancer, lactose, is low (8 mg). Lactose is a water-soluble filler and diluent; upon contact with dissolution media, it dissolves rapidly, creating pores within the tablet matrix. This sustained release can be attributed to the use of the hydrophilic polymer (HPMC) that acts as a release retarding agent [

62,

63]. However, F6 follows a similar % MLT release profile, at t ≥ 1 h, to Circadin

®. F10 shows an average % MLT release pattern, when compared with the F2 and F10 formulations; indicatively at t = 2 h, the release is 59.93% (

Figure 6c). In this formulation the quantity of the gel forming MCC formulant is higher than in the other two formulations.

According to the MLT release kinetics obtained via the Korsmeyer–Peppas equation (

Table 3), it is concluded, that from the F2, a Super Case II MLT release mechanism is followed, whilst from the F6 and F10 formulations, the non-Fickian/anomalous diffusion release mechanism (0.45 < n < 0.89)—i.e., a combination of simple diffusion and Case II anomalous diffusion transport release mechanism—is predominant.

Figure 6d shows the % MLT release vs. time from the F3, F7, F11 formulations, and Circadin

®. These formulations are comprised of the same polymeric material, PLA-glycerol, differing in the relative amounts of this particular excipient and also in the relative amounts of the other formulants of which they consist. The release of MLT from the F3, F11 formulations, and Circadin

®, at t = 2 h, shows a very similar release pattern. Formulation F3, at t ≥ 3 h, exhibits faster MLT release than the other three, rendering it a suitable candidate for confronting sleep onset problems. From the F7 formulation, which contains a larger quantity of HMPC, MLT release is 34.2%, at t = 2 h, and remains low, reaching 80.1%, at t = 8 h. This slower release rate is related to the greater amount of HPMC used [

64,

65,

66]. In view of this, F7 could be considered as a promising formulation in dealing with sleep maintenance dysfunctions. The F11 formulation, at t ≥ 2 h, shows an average % MLT release pattern, when compared with the other two PLA-glycerol containing formulations.

According to the MLT release kinetics data, obtained from the Korsmeyer–Peppas equation (

Table 3), it is concluded that the F3, F7, and F11 formulations follow a non-Fickian/anomalous diffusion release mechanism (0.45 < n < 0.89), i.e., a combination of simple diffusion and Case II anomalous diffusion transport.

Figure 6e,f, depicts the % MLT release vs. time from the F4, F8, F12, F13, F14, F15, F16 formulations, and Circadin

®. These formulations are comprised of the same polymeric material, PLA-pentaerythritol, differing, however, in the relative amounts of this excipient and in the relative amounts of the other formulants they are fabricated from. MLT release from the F4 formulation is the highest of all, conversely to the hormone release from F8, being the lowest of all the remaining PLA-pentaerythritol containing formulations. This is due to the 7.4-fold increase in the amount of HPMC in F8 compared to F4 and the double PLA-pentaerythritol content in F4 (67 mg vs. 33 mg). Thus, F4 could be viewed as a sleep onset promoting formulation, with F8 as a sleep maintenance pharmaceutical product.

Interestingly, the release of MLT from the F12 formulation is very similar to that from Circadin®, differing from F4 only in the relevant amounts of sodium alginate they contain; in F4 the amount of sodium alginate is 11-fold higher than in F12. It is well documented that at pH ≥ 3, sodium alginate exists as a salt, and not in the form of alginic acid, which, conversely to the salt, does not facilitate the aqueous dissolution of the APIs. Thus, the higher the content of sodium alginate in a formulation, the greater is the dissolution enhancement. In view of these findings, it could be suggested that the F4 formulation is a suitable candidate for dealing with sleep onset dysfunctions, whilst the F8 formulation could be suggested for confronting sleep maintenance problems. Their congeneric F12 formulation seems to be a promising Circadin® competitor.

According to the data, in terms of MLT release kinetics obtained for the F4 and F12 formulations, via the Korsmeyer–Peppas equation (

Table 3), it is concluded that the hormone release follows a non-Fickian/anomalous diffusion release mechanism (0.45 < n < 0.89), i.e., a combination of simple diffusion and Case II anomalous diffusion transport.

Apart from the F15 formulation the rest of the PLA-pentaerythritol formulations (F13, F14, and F16,

Figure 6f) have incremental differences in their composition, and this is mirrored in their release profiles. It is worth mentioning that the release of the hormone from F14 follows a very similar pattern to that from Circadin

® at t ≥ 4 h.

According to the data on the MLT release kinetics from the F13, F14, F15, and F16 formulations, obtained by the Korsmeyer–Peppas equation (

Table 3), it is concluded that a non-Fickian/anomalous diffusion release mechanism (0.45 < n < 0.89)—i.e., a combination of simple diffusion and Case II anomalous diffusion transport—is followed.

Preliminary findings suggest that the formulations maintain a reproducible release profile within the initial study period. However, further extended stability testing is required to confirm long-term integrity and ensure that MLT dissolution characteristics remain unaffected under various storage conditions.

Overall, comparing these findings with those observed in our previous work, involving PLA, PLA-

co-PEAd, and PLA-

co-PBAd derivatives in MLT matrix tablets [

44], it was found that in the present case the sought hormone delivery switch (sleep onset/sleep maintenance) was easier to achieve, mainly due to the difference in the relative number of hydrogen bonds between the C5-OMe H-bond acceptor moiety in melatonin and the H-bond donor OH groups in the PLA-sorbitol, PLA-glycerol, and PLA-pentaerythritol copolymers, respectively.