Water is essential for life on earth. Unfortunately, this precious and increasingly scarce resource is often polluted by various industrial discharges and organic substances. A lack of clean water can lead to serious problems for aquatic life and human health. The textile industry is responsible for a large proportion of the world’s water pollution through wastewater containing reactive dyes that affect the physico-chemical properties of water [1]. The complexity of textile wastewater lies in the presence of synthetic dyes with varied structures and intense colors [2]. These dyes are often toxic compounds that are difficult to biodegrade due to their complex structures and high stability. Their direct release into the environment without appropriate treatment can have harmful consequences for humans and the ecosystem [3,4]. It is therefore essential to break down these organic dyes before discharging the effluent from dyeing plants. Economical and effective treatment remains a challenge.

Advanced oxidation processes (AOPs) have recently emerged as a promising technological alternative for treating polluted water. In particular, heterogeneous photocatalytic oxidation is recognized as being particularly effective in generating highly reactive hydroxyl radicals (OH•) and superoxide anion radicals (•O2−), making it the most suitable method for wastewater decontamination [5,6]. The use of semiconductors with a band structure adapted to the redox potentials of O2/•O2− and OH•/H2O couples [6,7,8] in photocatalysis is gradually emerging as a promising alternative for the elimination of soluble organic compounds. Using this technique leads to the complete mineralization of these pollutants into carbon dioxide, water and mineral acids even at ambient temperature and atmospheric pressure.

The optical properties of a semiconductor depend on the conditions under which it is manufactured [9]. From a photocatalytic point of view, a wide-bandgap semiconductor such as TiO2 is only active under UV radiation, which represents only a low percent of the sunlight spectrum. Improving the absorption of wide-bandgap semiconductors in the visible range to make them more efficient under solar irradiation remains a challenge and the focus of intense research. In addition, their reactive surface area and, at the same time, their photocatalytic performance are significantly increased by their elaboration in the form of nanostructures.

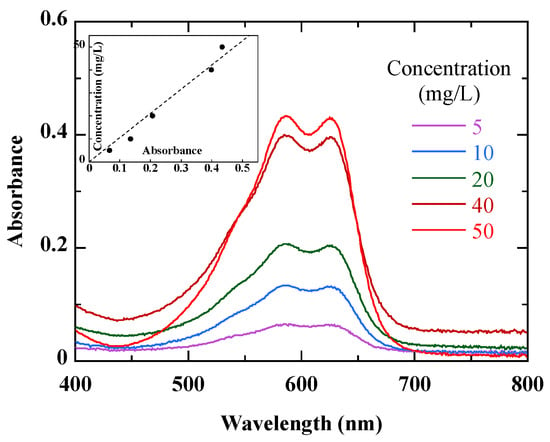

In the category of photocatalysts commonly used in nanoparticle form, TiO2 remains the most attractive and best-performing [10]. Interest in this photocatalyst has also motivated research into its production using increasingly environmentally friendly methods [11,12]. However, its high bandgap energy of 3.2 eV, which limits its photocatalytic activity to the UV region, makes its use limited [13]. TiO2-P25 is widely recognized as the commercial photocatalyst of reference, although the photocatalytic properties of TiO2 Hombikat UV100 have also been widely studied [14], particularly in liquid-phase applications [15]. As a photocatalyst, the higher efficiency of TiO2-P25 compared with TiO2-UV100 reported in some studies is mainly attributed to its mixed-phase nature, which allows better charge separation [16,17]. Other studies reported contradictory results, highlighting the superiority of UV100, mainly due to its greater capacity to adsorb pollutants and generate OH• radicals [14]. A smaller crystallite size would result in a better balance between surface and bulk photogenerated charge recombination. The removal of Reactive Blue 49 (RB49) dye in solution by various techniques has resulted in a great deal of work [18,19]. In this work, the solar photocatalytic degradation of RB49 is investigated by comparing the efficiency of these two TiO2-based photocatalysts: TiO2-P25 and TiO2-UV100. The Reactive Blue 49 (RB49) dye was chosen because it is one of the most widely used and environmentally harmful dyes in the textile industry. In addition, its degradation can be easily monitored by the discoloration of the solution over time. These photocatalysts were previously characterized by various techniques, including X-ray diffraction (XRD), Fourier-transform infrared (FTIR) spectroscopy and scanning electron microscopy (SEM). We first studied the adsorption kinetics of the dye on the photocatalyst, before investigating its photocatalytic performance and the different parameters that can affect it (photocatalyst loading, dye concentration and solution pH). Through this work, we hope to contribute to the resolution of this open debate on the quality of the photocatalytic performance of these two TiO2-based photocatalysts.

Source link

Fatima Zaaboul www.mdpi.com