4.1. Washing, Sanitation, and Antimicrobial Interventions

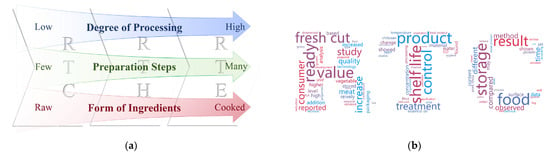

Due to the nature of RTC foods, most of them need to be initially washed and sanitized to remove debris and microbial load, then pre-cooled for the cold chain [38], as shown in Figure 3. They also need to be treated with antimicrobials along with the washing or by adding antimicrobial components inside the package, i.e., antimicrobial interventions (essential oil [39], organic acid [40], chitosan [41], etc.), in order to maximize the shelf life of the unsterilized ingredients; in addition, pathogenic contamination needs to be prevented.

Most RTC foods are assembled from washed raw materials, they require different levels of cleaning. Particularly, the processing of fresh produce into RTC involves three essential water washing stages: primary washing, washing and sanitizing, and rinsing [42,43]. The primary washing serves to eliminate large impurities, such as soil particles, insect fragments, etc., from unpeeled vegetables, while the cleaning and sanitizing phase is critical for minimizing microbial attachment and enhancing shelf life. The final rinsing step is designed to remove any residual detergent [42]. Meanwhile, for meat carcasses, washing after skinning and before gutting is useful to reduce microbial adhesion [44], in addition to washing at the end of slaughter and before freezing or refrigerated processing as an important step in decontamination [45], e.g., washing in hot and cold water, lactic acid decontamination. Fresh seafood exhibits a high degree of perishability following harvest, necessitating immediate processing, which includes cleaning, trimming, peeling, and gutting [46]. For instance, oysters require thorough washing with water to remove any mud, followed by prompt shucking, which can be achieved through methods such as steaming or infrared heating [47]. Similarly, lobsters should be meticulously cleaned without delay, taking care to shield them from sunlight and direct winds, before being subjected to freezing for preservation [48].

In the washing processes of these raw materials, in addition to large particles of impurities, reducing microbial load is another key task. Spoilage microorganisms can easily proliferate on food matrix rich in nutrients, which are heavily exposed to the environment post-processing [49,50]. Meanwhile, fresh produce and meat carcasses may harbor pathogenic bacteria such as Escherichia coli, Salmonella, Staphylococcus aureus, Campylobacter spp., and Listeria monocytogenes [45,51,52]. While seafood products are of particular concern due to the presence of Vibrio spp. [53] and L. monocytogenes [54]. Contamination with both spoilage and pathogenic microorganisms may occur at any point of the processing or even during the packaging and distribution, necessitating urgent cleaning and intervention measures [52,55,56]. Therefore, water washing works as a multi-purpose approach that can handle the above-mentioned issues within a single process. The related technologies can be divided into physical and chemical, but in most cases, they are used in combination with each other to reach the optimized efficiency [15,57].

The most frequently used chemical approach for sanitizing RTC foods is adding chlorine-based sanitizers when washing them [58]. Needless to say, chlorine-based disinfectants are effective in reducing initial microbial loads; the commonly used disinfectant sodium hypochlorite (NaOCl) has strong oxidizing properties and is bactericidal against a wide range of microorganisms such as bacteria, viruses, fungi, and protozoa. However, the effectiveness of chlorine relies heavily on the wash water quality [17], resulting in unreliable antimicrobial effects. Other chemical sanitizers developed for washing and sanitation include chlorine dioxide, PAA, ozone, and electrolyzed water [58]. These novel sanitizers have not been widely applied by the food industry, although their antimicrobial efficacy was demonstrated [59,60]. For instance, Al-Holy and Rasco (2015) [59] applied acidic electrolyzed water on trout, chicken, and beef muscle for 10 min, causing, respectively, reductions of 1.5, 1.5, and 1.4 log in Salmonella Typhimurium and reductions of 1.2, 1.1, and 1.3 log in L. monocytogenes. The main concerns are the increased cost and safety risks in a large-scale production scenario [61,62,63,64].

Normally used physical techniques include turbulence- and bubble-assisted washing, which are extensively employed to improve mass transfer [65,66]. Novel ultrasound- or microbubble/nanobubble-assisted washing methods have also been investigated with increasing interest in recent years [67,68]. The cavitation and shearing effects of ultrasound or bubbles can inactivate or scrub microorganisms through mechanisms of cavitation and shear forces without leaving any dead space, and help to maintain the quality characteristics of agricultural products [69,70], especially fragile leafy vegetables. However, the implement of these technologies for food cleaning is currently limited to a laboratory scale and has not yet been adopted for commercial food products [71,72]. By optimizing the cleaning conditions for single-frequency ultrasound using response surfaces, Alenyorege et al. (2020) [73] found that the removal of 5.6 and 4.7 CFU/g for E. coli and L. innocua respectively could be achieved by washing Chinese cabbage for 15 min using ultrasound with a frequency of 40 kHz and a power of 125.45 W/L. Ozone micro- and nanobubbles with an ORP of 860 ± 42 mV were sufficient to reduce Streptococcus agalactiae or Aeromonas veronii concentrations by 26- to 48-fold, corresponding to a reduction exceeding 96%, when applied to tilapia products for 10 min [67]. These new techniques overall demonstrated significantly improved cleaning and sanitation efficacy, particularly when applied simultaneously with chemical sanitizers [66,74].

In other cases, some RTC foods are not suitable to be washed or sanitized. Irradiation is an alternative way for microbial mitigation, without compromise in food quality. Gunes et al. (2011) [7] treated ground beef patties with different doses of irradiation and found that L. monocytogenes was effectively inactivated at a dose of 3 kGy, whereas E. coli was inactivated at a lower dose of 1.5 kGy. Furthermore, the shelf life of the ground beef product was extended to 21 days when stored at a temperature of 3 °C. The application of ultraviolet light (UV-C) light-emitting diodes (LEDs) at wavelengths of 250–280 nm for the disinfection of skinless chicken breasts contaminated with Salmonella enterica yielded a reduction of 1.02 and 1.78 Log CFU/cm2 after exposure for 1 min and 15 min, respectively [75]. Irradiation technologies, including ultraviolet (UV) light, are currently employed in commercial applications due to their low cost and absence of residuals, but mainly in liquid food products [76]. Similarly, other techniques such as high-pressure processing also demonstrated effective application in antimicrobial intervention of RTC seafoods. Kural et al. (2008)’s [77] research indicated that applying a pressure of at least 350 MPa for 2 min at temperatures ranging from 1 to 35 °C, or a pressure of at least 300 MPa for 2 min at 40 °C, resulted in a reduction of 5 log in the inactivation of Vibrio parahaemolyticus in oysters. A summary of representative studies with novel antimicrobial intervention technologies for RTC foods are listed in Table 1.

In the case of solely antimicrobial intervention, many food grade compounds demonstrated the suitability when directly added into the food or its brine inside packages. for example, essential oils (e.g., rosemary oil and thyme oil) exhibit broad-spectrum antimicrobial effects by disrupting bacterial cell membranes and are commonly used to prolong the shelf life of meat and vegetable RTC foods [78,79]. Nisin, a naturally occurring antimicrobial peptide produced by lactobacillus bacteria, is able to inhibit the growth of gram-positive bacteria, and is particularly suited to controlling Listeria monocytogenes in meat products [80].

Table 1.

Representative cleaning, sanitation, or antimicrobial techniques used for pathogen control in RTC foods.

Table 1.

Representative cleaning, sanitation, or antimicrobial techniques used for pathogen control in RTC foods.

| RTC Food | Techniques | Treatment Conditions | Effectiveness | References |

|---|---|---|---|---|

| Washed vegetables | Electrolyzed water | 50 ppm of free chlorine, 45 s | 4 log CFU/g Salmonella inactivation | [81] |

| Tomato beef brisket | Peroxyacetic acid | 10 mg/L, 30 s | Prevent cross-contamination with 106 log CFU/g Salmonella | [60] |

| Chicken skewer | Peroxyacetic acid | 0.07%, 15 s | 2.0 log CFU/mL reduction in aerobic bacteria and Salmonella | [82] |

| Thick-cut grilled meat slices | Chlorine dioxide | 200 ppm/400 ppm, 30 s | 0.73/1.25 log CFU/g E. coli O157:H7 inactivation | [83] |

| Trout fillet | Acidic electrolyzed water | pH 2.30, free chlorine: 38 ppm, 10 min | 1.5 log Salmonella Typhimuriu and 1.2 log L. monocytogenes reduction | [59] |

| Korean Army stew | Ultrasound | 40 kHz, 125.45 W/L ultrasound power, 15 min | 5.6 and 4.7 log CFU/g for E. coli and L. innocua reduction, respectively | [73] |

| Washed vegetables | Ultrasound | 40 kHz, 100 W/L, 1 min | 2.5 and 2.6 log CFU/g for E. coli and L. innocua reduction respectively | [84] |

| Beef patty | Gamma irradiation | 3 kGy/1.5 kGy | totally inactivating L. innocua and E. coli respectively | [77] |

| Riced cauliflower | Irradiation | 0.5 kGy | 2 log CFU/g inactivation of total aerobic bacteria | [5] |

| Spicy crayfish | High-pressure processing | ≥350 MPa at 1–35 °C or ≥300 MPa at 40 °C, 2 min | 5.0 log cfu/g Vibrio parahaemolyticus inactivation | [77] |

| Clean tilapia fillets | Peroxyacetic acid | 300 ppm, fogging, 15 min | 1.66 CFU/g Salmonella reduction | [85] |

| Hairtail fish balls | High-pressure processing | 300 MPa, 5 min | 707.67 CFU/g total colony reduction | [86] |

4.2. Peeling- and Cutting-Related Technologies

RTC foods post initial cleaning are submitted to subsequent steps such as peeling of fresh produce, skinning of meat, shell removal from shellfish, and cutting. By converting the raw materials to nearly 100% edible portion, these processes greatly reduce the preparation time for consumers during cooking and may assist them in completing complex and delicate food preparation [47]. Currently, for many RTC foods, these procedures are still completely or partially reliant on manual work, while some others are already performed with machinery [87].

Fresh produce RTC foods, such as potatoes and tomatoes, require peeling before further processing. Traditionally, peeling of fresh produce often involves methods such as lye peeling and steam peeling; these methods are efficient but have drawbacks such as high energy consumption, high peeling losses, and environmental concerns [18]. In recent years, researchers have been trying out new peeling techniques for fruits and vegetables, such as ohmic heating [18,88], infrared peeling [89], and ultrasonic peeling [18]. These techniques are less intense thus posing minimal impact on product quality and will be suitable for future fresh produce RTC foods. Skinning of meats relies more on physical separation by specially designed equipment; large-volume processing also requires a standard supply of animals whose physical properties, such as dimensions, are compatible with the processing line [90,91]. In the category of RTC seafood, some fish products only need to have their scales removed; however, shell removal from shrimp and oysters is more challenging and still heavily relies on manual work in small-scale processing. In recent years, researchers have found that high-pressure technology can be applied to the peeling of shellfish. For example, Xuan et al. (2018) [92] have used high-pressure technology to achieve peeling of fresh razor clams; the shelling rate reached up to 100% for a holding time of 10 min at a pressure of 200 MPa or 1 min at a pressure of 400 MPa.

For the cutting step, high-speed cutting technology, which predominantly utilizes a mechanical cutting mode, is the most prevalent method employed in food processing facilities. The technology has been used in the processing of RTC meat, vegetables, and dairy products. However, higher cutting accuracy has been demanded [93] in order to prevent substantial food residue generation [94]. For example, when dealing with separation of specific part of animals or fish, such as steaks or fish heads, it is essential to achieve precise cutting to obtain the exact portion. More innovative cutting technologies have emerged, including ultrasonic vibration-assisted cutting, laser cutting, and water jet cutting. However, ultrasonic vibration-assisted cutting is deemed inappropriate for the processing of vegetables and meat due to the significant enzymatic reactions that occur in the effluent, as well as the potential for thermal damage [95]. Laser cutting and water jet cutting are classified as non-contact cutting methods. Laser cutting is a thermal cutting technique that involves directing a concentrated laser beam onto the material’s surface, resulting in rapid localized heating that facilitates fine structural separation; this makes laser cutting more appropriate for customized processing applications [96]. However, this method is not suitable for materials that are sensitive to heat. In contrast, water jet cutting is a non-thermal technique that utilizes the substantial kinetic energy of a high-speed water jet to impact and separate the material [97]. This approach also supports custom processing and can be combined with advanced technologies such as computer vision, making it particularly appropriate for soft materials in the processing of RTC foods, such as vegetables. For meat cutting, high-pressure water jets may be a better choice; they are able to cut bones with a higher level of cutting force than normal water jets [98]. These advanced methods offer enhanced precision and quality in cutting processes, thereby providing safer and more efficient alternatives. Additionally, some of the food materials need to be smashed, powdered, or even reconstituted to maximize the flavor or provide a more pleasant mouthfeel when used in RTC foods [99,100,101].

4.3. Marination Technology

Marination is a pivotal process in the preparation of ready-to-cook meals, as it substantially enhances the organoleptic properties, including both taste profile and mouthfeel [19,102]. During the traditional marination, foods are soaked in a marinade, e.g., salt solution, soy sauce, or customized sauce, over several hours or overnight. This is effective for infusing flavor but is less efficient for RTC meals that require quicker processing times. Furthermore, traditional marination can result in uneven flavor penetration, especially in larger or denser items [103]. Typically, marination times of 12 to 24 h are needed for adequate flavor absorption in vegetables and small cuts of meat or fish. Traditional marination is cost-effective, requiring only basic kitchen tools or industrial vats, which are significantly cheaper compared to advanced technologies [19].

In contrast, newer techniques with commercial applications include vacuum marination, injection marination, and tumblers [104,105,106]. Vacuum marination accelerates this process by reducing air and enhancing the penetration of flavors, while injection marination quickly infuses flavors into large volumes of product, making it efficient for high-throughput operations. Tumblers and rotating drums provide uniform flavor distribution and tenderness through mechanical agitation, which is ideal for bulk processing. More specifically, vacuum marination uses a vacuum chamber to remove air, creating a pressure differential that accelerates marinade absorption. J. and M. (2023) [107] highlight that this method reduces marination times from 12 h to 1–2 h for meats and poultry. However, the cost of vacuum marination equipment varies widely, with smaller machines costing between $2000 and $5000, while industrial systems such as the BLENDTEC 3500 lb tumbler can cost more than ten times as much [108]. This method is particularly effective for RTC meals due to its ability to enhance the penetration of key flavor components quickly and uniformly. Vacuum marination works by creating a low-pressure environment that expands the food’s cellular structure, allowing marinade components such as sodium, spices, and acids to diffuse more rapidly and deeply into the food. This is facilitated by the removal of air pockets and the creation of a pressure gradient that drives the marinade into the food matrix. Optimizing parameters such as vacuum pressure (≥400 MPa) and marination duration can further improve the uniformity of flavor and seasoning, ensuring that critical components reach the deeper parts of the food efficiently. Injection marination involves directly injecting marinade into food using needles or pumps, allowing rapid flavor infusion within 15 to 30 min for large cuts of meat or poultry [104,109]. This method is highly effective for RTC meals where uniform flavor distribution is essential. The cost of commercial meat injectors ranges from $5000 to $50,000 depending on automation and capacity [110]. However, careful control of injection parameters, such as pressure and volume, is required to prevent texture changes. Injection marination is beneficial for large or dense items that need quick marination before cooking. Tumblers or rotating drums continuously tumble food with the marinade, processing it within 30 min to 2 h, depending on the product and desired flavor level [111]. Tumblers vary in cost, with smaller models available for as little as $6500, while larger industrial models can reach up to $35,000 [112]. The key parameters include tumbling speed and drum rotation time, which ensure even coating and flavor distribution.

Emerging technologies primarily studied in laboratory settings include high-pressure processing (HPP), ultrasound marination, and electro-magnetic fields (EMF) [113,114]. HPP applies high pressure to enhance marinade absorption, achieving uniform flavor infusion in just a few minutes while preserving food texture. However, HPP has certain limitations that hinder its broader application. For instance, HPP-induced lipid oxidation, baroresistance of bacterial spores, and changes in food color are some significant challenges of this technology [115]. Moreover, HPP equipment is relative expensive, ranging from $500,000 to $2.5 million [112]. Pressures of 400–600 MPa applied for 3 to 5 min have been shown to provide superior marinade penetration and preservation of food texture. HPP is ideal for RTC meals such as marinated meats and seafood, where rapid flavor infusion and high-quality preservation are critical [116,117]. Although HPP provides superior marinade penetration and texture preservation, pressures of 400–600 MPa applied for 3 to 5 min may not fully inactivate bacterial spores, requiring supplementary techniques such as cold-chain handling for safety [118]. Ultrasound marination uses high-frequency sound waves to accelerate the marination process, reducing times to 20–40 min. Costs for ultrasound systems range from $20,000 to $100,000, depending on capacity and system sophistication [108]. This method is effective for various food categories, including meats and vegetables, where faster marination is advantageous. The technology involves optimizing frequency and power settings to enhance absorption rates while maintaining food quality [107]. EMF technology employs electromagnetic fields to improve marinade absorption, though it remains an emerging and costly technology with potential benefits for rapid and uniform flavor distribution. Zhang et al. (2023) [78] indicate that EMF can enhance flavor penetration effectively, though it is still in the experimental stage and is comparable in cost to ultrasound marination [108]. The method shows potential for a wide range of food categories, including meats and vegetables, with the ability to achieve uniform marinade distribution rapidly.

Each marination technology offers unique advantages based on factors such as efficiency, processing scale, and food categories. Their application scope and specific characteristics are listed in Table 2.

Table 2.

Comparisons among marination technologies used for RTC foods.

Table 2.

Comparisons among marination technologies used for RTC foods.

| Technology | Molecular Mechanism | Marination Efficiency | Food Categories | References |

|---|---|---|---|---|

| Traditional Marination | Flavor molecules move via simple diffusion from higher to lower concentrations. Outer layers absorb most flavor; center less affected. | Relatively slow (12–24 h). | Vegetables, small cuts of meat, fish | [103,119] |

| Vacuum Marination | Reduced air pressure in vacuum chamber speeds up marinade diffusion, removing air pockets and enhancing infiltration into food spaces. | High; faster than traditional (1–2 h). | Meats, poultry, fish | [103,105,107,120] |

| Injection Marination | Marinade penetrates food interior uniformly through injection channels, distributing salts, sugars, and flavors evenly. | High; precise and fast (15–30 min). | Large cuts of meat, dense products | [104,112,121,122] |

| Tumblers/Rotating Drums | Constant tumbling increases contact between marinade and food, facilitating uniform and rapid marinade absorption. | High; effective for large batches (30 min to 2 h). | Meats, poultry, seafood | [106,111,123,124] |

| High-Pressure Processing (HPP) | High pressure disrupts cell membranes, enhancing food matrix permeability for deeper, uniform marinade penetration. | Very high; rapid and deep penetration (3–5 min). | RTC meals, high-value products | [21,120,125,126] |

| Ultrasound Marination | Ultrasonic waves generate cavitation, causing micro-shocks and turbulence that mix marinade and enhance flavor molecule absorption. | High; faster absorption (20–40 min). | Meats, seafood, vegetables | [107,127,128,129] |

| Electro-Magnetic Fields (EMF) | EMF technology interacts with the food matrix, influencing marinade component movement and absorption. | Potentially high; still developing. | Meats and vegetables | [93,113] |

4.4. Frying Technology

Frying is another important process to achieve a unique flavor and desirable texture in RTC foods. Common frying technologies in the current market include deep-fat frying, vacuum frying, and air frying. Traditional deep-fat frying refers to immersing food in high-temperature oil and utilizing heat conduction to rapidly dehydrate the surface of the food and form a crispy outer shell. It is widely used for products such as meat and aquatic products, in which, by virtue of its high efficiency and rapidity, it results in a crispy outer surface and a tender inner surface, but it can easily lead to a high fat intake and pose a health risk [130,131]. Vacuum frying is suitable for the production of dried vegetables, which can retain more nutrients and natural color under low-temperature and low-pressure environments, but the high cost restrained its applications in RTC vegetables such as carrot crisps [132]. Due to the configuration of frying process inside a vacuum chamber, such processes are essentially of the batch type and have limited throughput. Even a large piece of equipment 12 m long and 3 m wide can only produce about 350 kg of product per hour, and the equipment is relatively expensive [131]. Air frying uses circulating hot air instead of fat to significantly reduce fat content, in line with the trend of healthier diets, but differs from traditional deep frying in terms of taste [130,133,134].

Frontiers in frying technology studied for RTC applications focused on the coupling technology of vacuum frying with microwave, ultrasound, or radio frequency in a targeted manner according to product characteristics to obtain higher-quality pre-fried food [133,135]. Microwave-assisted vacuum frying (MVF) integrates microwave heating within a vacuum environment by uniformly positioning microwave generators around the frying chamber. This technology leverages microwave energy to enhance the heating and water evaporation of food products, significantly reducing the fat content of food products while improving the color and crunch, and it is suitable for the production of high-quality RTC vegetables, meats, and aquatic products [133,136,137,138]. In studies conducted by Su et al. (2016), Su et al. (2018), Zhang et al. (2020) and R. et al. (2021), microwave power levels of 600 W to 1000 W were used, with frying times of up to 360 s. This approach significantly reduces fat content, with one study showing a decrease from 39.14 g/100 g to 29.35 g/100 g during the frying of potato chips [136,137,139]. While MVF allows for the production of crunchy food products and maintains the basic quality of the product, the process requires longer processing times, resulting in higher operating costs and investments [140]. Pulse-spouted microwave vacuum frying (PSMVF) uses intermittent pulses during the frying process instead of continuously spraying oil onto the food. This pulse allows for more precise control of the amount and coverage of oil, reducing oil consumption and optimizing thermal efficiency through intermittent heat input, enabling precise control of the process. This is particularly beneficial for RTC root vegetables with high starch content, such as potatoes, because the method efficiently manages the moisture content critical to maintaining texture and flavor after frying [137,141]. In a study by Su et al. (2018), pulse-jet microwave technology combined with vacuum frying at 90 °C was shown to reduce fat content by 16–34% [142], while maintaining the desired color [143,144,145]. However, research on PSMVF is still at the laboratory stage with no commercial usage yet. Ultrasonic microwave-assisted vacuum frying (USMVF), on the other hand, introduces ultrasonic waves on the basis of MVF, which enhances the rate of water evaporation through the cavitation effect, reduces the absorption of oil and fat, and causes more nutrients and color to be retained. The USMVF is suitable for the efficient processing of various RTC foods. For example, in the processing of purple potato chips, USMVF not only shortens the frying time but also significantly improves the retention of anthocyanins [139]. This is particularly advantageous for producing heathier RTC fried foods since high temperature frying can hardly improve the retention of heat-sensitive components, which are usually important portion of the nutrients. Studies by Su et al. (2018), Islam et al. (2019), and Zhang et al. (2020), at ultrasound power levels of 300 W to 600 W, coupled with microwave power of 600 W to 800 W, shortened frying time while improving the retention of anthocyanins and nutrients. The cavitation effect from ultrasound accelerates moisture removal, improving texture and crispness while reducing oil content by 16–34% [133,142,146]. The technology is particularly effective at lower frying temperatures, making it suitable for items with sensitive nutritional components that might degrade at higher heat. This method shows a promising reduction in drying time by 20–28%, and the enhanced moisture evaporation rates lead to improved product crispness and reduced oil content [139,147]. The integration of ultrasound technology into MVF is also cost-effective, as the equipment costs about 1/10 of the total cost of the frying setup. The energy used by the ultrasound is significantly less than that used by the microwave source and vacuum pump, reducing overall energy consumption. This makes USMVF an economically viable alternative that enhances the quality attributes of fried products at lower temperatures, suggesting that combining ultrasound with MVF could be a beneficial technique for producing high-quality fried products efficiently [139].

Additionally, capabilities for reheating or re-frying of pre-fried RTC foods are important consideration, involves using ovens, air fryers, or microwaves to restore the original texture and flavor, bringing the food closer to a freshly prepared state [148,149]. It has been shown that the physical structure of the food significantly affects the amount of fat absorbed during the re-frying of frozen pre-fried foods, such as frozen French fries and battered fish fillets, and that lipid intercalation is evident. The use of different types of oils during deep-frying produced differences in the major fatty acid content of the foods and showed less preferential adsorption of polar compounds on the food surface [150,151]. By optimizing the breading formulation and frying parameters, microwave-heatable pre-fried foods can effectively maintain crispiness after re-frying, but large-scale economic production still faces challenges [152,153]. In the case of beef skewers, for example, the refrying conditions of 190 °C and 60 s can significantly improve their yield, color and sensory quality [154].

Source link

Tianqi Cui www.mdpi.com