4.1. Thrust Range

In the course of a comprehensive thruster performance test, the thrust range is of primary interest. A closed-loop flow control method was adopted to give a specific flow value to the thruster. At the same time, a high-precision thrust test bench monitored and recorded, in real time, the pressure, thrust and displacement data generated by the thruster at the given flow rate. The displacement data were converted into needle valve opening values, and then a large amount of corresponding one-to-one experimental data was collected. After data analysis and processing, the corresponding relationship curves among flow, thrust, and the needle valve opening were constructed.

The results are corroborated by the gradual decrease in pressure. This result demonstrates that the needle valve can move quickly under high flow conditions with closed-loop flow control, and that the thrusters have good performance stability, meeting the demand for higher thrust output under high flow conditions.

Using this relationship, we calculated the flow value corresponding to any thrust value within the range of 1300 μN and vice versa. This allowed us to obtain a more in-depth understanding of the thruster’s performance and to grasp its flow change law and overall operating characteristics under different thrust conditions.

The fit has a certain deviation in the mean displacement. There are two main reasons for this problem. One is that the needle valve material itself has a hysteresis characteristic. Due to this characteristic, the relationship between the displacement and thrust of the needle valve in the process of movement is not completely linear, but has certain hysteresis and non-linear factors, which poses considerable challenges to the fitting work. Secondly, the change in tank pressure also affects the fitting accuracy. In the experimental process, the pressure is not always constant, and its fluctuation causes corresponding changes in the thrust, which in turn disrupt the normal correspondence between the displacement and thrust, making it difficult to fit the curve to the actual data.

4.2. Thrust Resolution

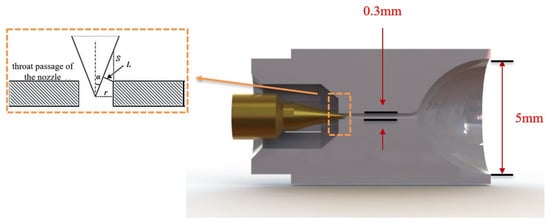

As a high-precision propulsion device, the design objective of the micro-Newton cold gas thruster is to achieve a wide range of thrust adjustments while ensuring high resolution and accuracy under the micro-Newton low-thrust output state. This is critical to meet the noise reduction requirements of spacecraft for complex space missions. During the experiment, a finely controlled small flow was input to the thruster, and the force frame results show that the output resolution in the small flow mode reached 0.1 μN.

It can clearly be seen in the figure that the flow sensor and displacement sensor of the thruster achieved the set accuracy, and the thrust test bench also detected the thrust change with this accuracy. When the flow rate changed by 0.2 μg/s, the resolution reached 0.1 μN. This result demonstrates that the thruster performed well in flow control accuracy and thrust output sensitivity and could sense and respond to small flow changes, thereby achieving precise adjustment of the corresponding thrust. The measurement accuracy of the force frame itself was also excellent, and it detected small thrust changes of 0.1 μN.

4.3. Thrust Noise

The frequency band of main concern is from 10−3 Hz to 1Hz. The band above 0.1 Hz had only one frequency point, 0.3 Hz, where the shear noise exceeded the set requirement threshold of 0.1 μN/Hz1/2. This frequency point corresponds to an oscillation period of approximately 3.3 s. In this case, the possible cause was the fluctuation in the flow rate. Rapid changes in the flow rate produce high-frequency disturbances, which are directly transferred to the thrust output and manifest themselves as high-frequency thrust noise. During the long-term operation of the thruster, due to the influence of various internal factors and the external environment, its performance may drift slowly. This drift will be reflected in the low-frequency fluctuation of the thrust, thereby affecting the stability of the thrust.

To further reduce thrust noise and improve thrust stability, the two key factors of voltage fluctuation and flow fluctuation can be optimized. For example, by adopting a more stable power supply system, the voltage can be precisely regulated to reduce the voltage fluctuation. At the same time, the flow control system can be optimized, and high-precision flow sensors and advanced control algorithms can be used to achieve precise control of the flow, thus reducing the flow fluctuation. To address the problem of drift in thruster performance, the monitoring and maintenance of the thruster can be strengthened, the performance of the thruster can be regularly calibrated and adjusted regularly, and problems that may cause performance drift can be detected and resolved on time to ensure that the thruster is always in a good operating state. By implementing these measures, it is expected that the thrust noise can be controlled at a lower level and meet more stringent performance requirements.

Source link

Songcai Lu www.mdpi.com